Jet pipe, fluidized bed reactor with jet pipe and coal catalyzing and gasifying method

The technology of a jet tube and a reactor is applied in the fields of fluidized bed reactor and coal catalytic gasification, coal catalytic gasification process, coal and biomass co-gasification process, and can solve the problem that the degree of back-mixing of solid particles is slow, the degree of turbulence is slow, the The problems of low gas-solid contact efficiency and easy slagging can reduce the risk of slagging, realize the self-heating of coal combustion, and strengthen the degree of heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

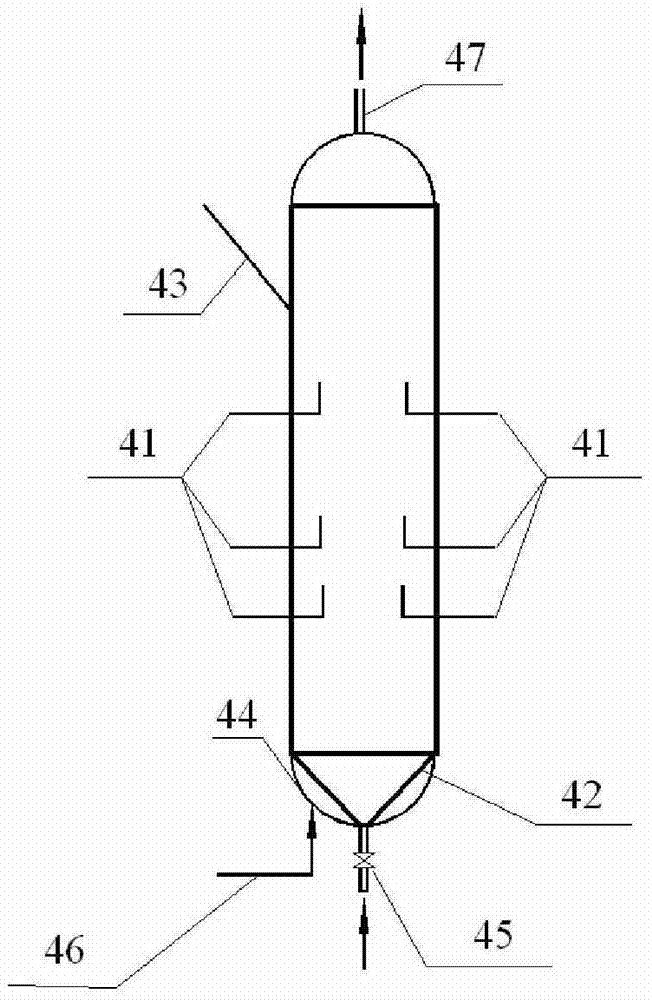

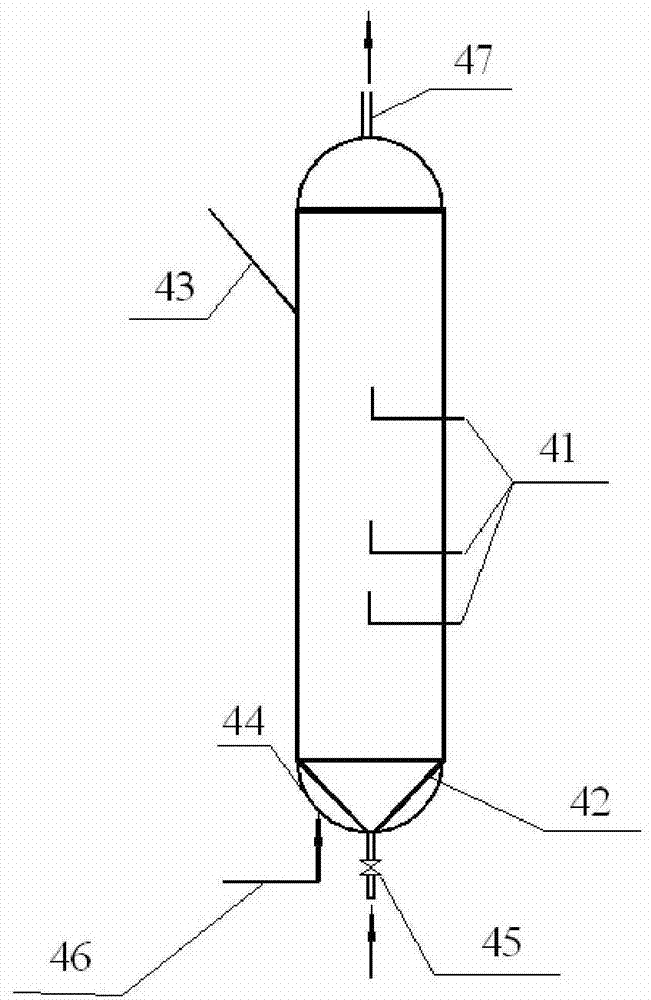

[0068] Such as figure 1 and figure 2 Shown, a kind of multi-jet fluidized bed reactor, described reactor comprises:

[0069] a reactor body, the interior of which forms a chamber;

[0070] A conical distribution plate 42 is located at the bottom of the reactor main body, forming an air chamber 44 with the wall of the bottom of the reactor main body;

[0071] The feed line 43 is arranged through the upper part of the reactor main body, and is in fluid communication with the chamber, so that the raw carbonaceous material enters the chamber;

[0072] The gasification agent pipeline 46 is arranged through the bottom of the reactor main body, and is opened to the gas chamber 44, so that the gasification agent enters the chamber through the conical distribution plate 42;

[0073] The bed gas distribution device 41 is arranged through the side wall of the reactor body and is in fluid communication with the chamber;

[0074] The discharge pipeline 47 is arranged through the top o...

Embodiment 2

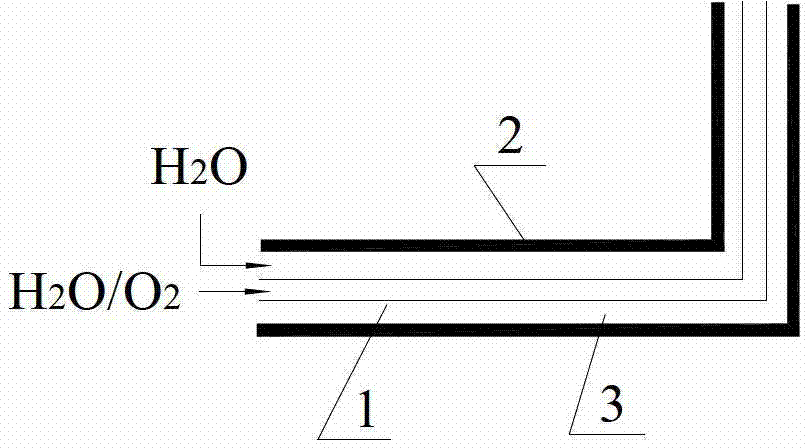

[0080] A method for coal catalytic gasification using a multi-jet fluidized bed reactor, the carbonaceous material impregnated with the catalyst enters the reactor chamber through the feed line 43, and the gasification agent passes through the gasification agent line 46 from the gas chamber 44 through After the conical distribution plate 42 evenly distributes the gas, it enters the reactor chamber, and the gasifying agent and the carbonaceous material undergo a gasification reaction under the action of the catalyst; the gasifying agent is superheated steam and O 2The mixed gas in which the oxygen concentration is 5mol%, and the water-to-carbon molar ratio of the gasification agent to the carbonaceous material is 3.

[0081] The central tube 1 of the jet tube as the bed gas distribution device 41 is fed with a mixture of oxygen and superheated steam, and superheated steam is passed into the annulus 3; the oxygen and carbonaceous materials undergo catalytic combustion to release ...

Embodiment 3

[0086] A method for coal catalytic gasification using a multi-jet fluidized bed reactor, the carbonaceous material impregnated with the catalyst enters the reactor chamber through the feed line 43, and the gasification agent passes through the gasification agent line 46 from the gas chamber 44 through The conical distribution plate 42 enters the reactor chamber after distributing the gas, and the gasification agent and the carbonaceous material undergo a gasification reaction under the action of the catalyst; the gasification agent is superheated steam, and the molar ratio of water to carbon is controlled to be 2.5;

[0087] The central tube 1 of the jet tube as the bed gas distribution device 41 is fed with a mixture of oxygen and superheated steam, and superheated steam is passed into the annulus 3; the oxygen and carbonaceous materials undergo catalytic combustion to release heat, which is a gasification reaction Provide heat; the superheated steam in the annulus 3 strengthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com