Composition for polymer membrane and polymer membrane

A polymer film and composition technology, applied in the field of polymer film compositions and polymer films, can solve problems such as unstable performance, high heat-sealing temperature, and uneven composition of propylene terpolymer, and achieve initial Low heat sealing temperature, good film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] This example serves to illustrate the composition for a polymer film and the polymer film according to the present invention.

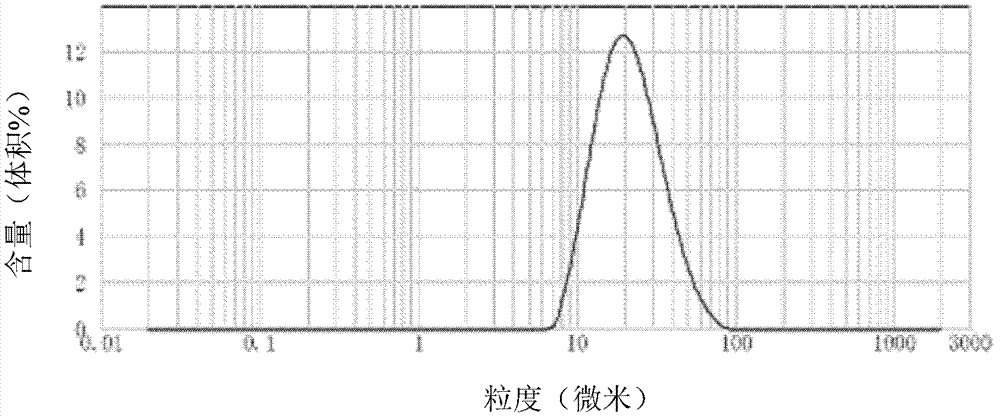

[0093] (1) Sieve the catalyst solid component (commercially purchased from Beijing Aoda Petrochemical Co., Ltd.), so that the particle size of the obtained solid component is 8-100 microns, and the particle size is a solid within the range of 14-30 microns The amount of the components is 80% by volume. Such as figure 1 As shown, the obtained particle size distribution curve of the solid component is a unimodal distribution.

[0094] The solid component uses magnesium chloride as a carrier, wherein, based on the total amount of the solid component, the content of titanium in terms of elements is 2.5% by weight, and the content of di-n-butyl terephthalate is 10% by weight.

[0095] Continuously feed the catalyst solid component into 50m at 0.63kg / h 3 In the continuous horizontal stirred bed gas-phase reactor, add triethylaluminum continuously ...

Embodiment 2

[0110] This example serves to illustrate the composition for a polymer film and the polymer film according to the present invention.

[0111] (1) The same method as in Example 1 is used to prepare propylene polymer, the difference is that the pressure in the reactor is 2.4MPa, the temperature in the reactor is 60°C, and the hydrogen in the reactor / propylene molar ratio (H 2 / C 3 ) is 0.013.

[0112] The composition and properties of the propylene polymers prepared are shown in Table 1.

[0113] (2) The polymer film was prepared by the same method as in Example 1, except that the propylene polymer was the propylene polymer prepared in step (1) of Example 2.

[0114] The heat-sealing initiation temperature of the prepared polymer films was measured and the results are shown in Table 1.

Embodiment 3

[0116] This example serves to illustrate the composition for a polymer film and the polymer film according to the present invention.

[0117] (1) The same method as in Example 1 is used to prepare propylene polymer, the difference is that the pressure in the reactor is 2.3MPa, the temperature in the reactor is 61°C, and the hydrogen in the reactor / propylene molar ratio (H 2 / C 3 ) is 0.017.

[0118] The composition and properties of the propylene polymers prepared are shown in Table 1.

[0119] (2) The polymer film was prepared by the same method as in Example 1, except that the propylene polymer was the propylene polymer prepared in step (1) of Example 3.

[0120] The heat-sealing initiation temperature of the prepared polymer films was measured and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com