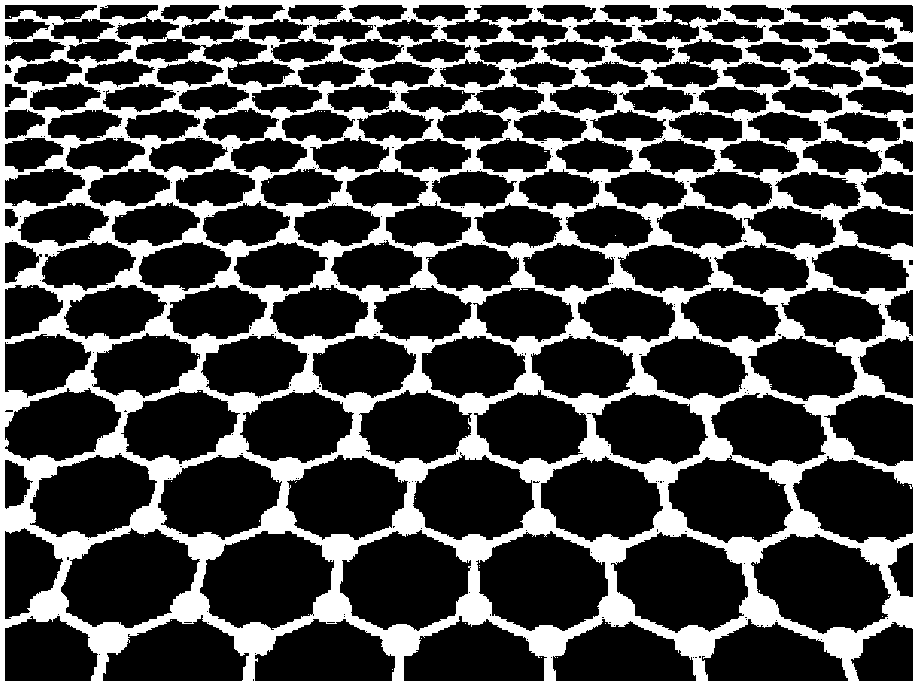

Method for preparing graphene organic dispersion solution from hyperbranched polyethylene

A hyperbranched polyethylene and graphene dispersion technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of weak dispersion and stability, decreased performance of graphene, low concentration of graphene, etc., and achieve less destructive surface structure , low concentration of surface defects, and mild polymerization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

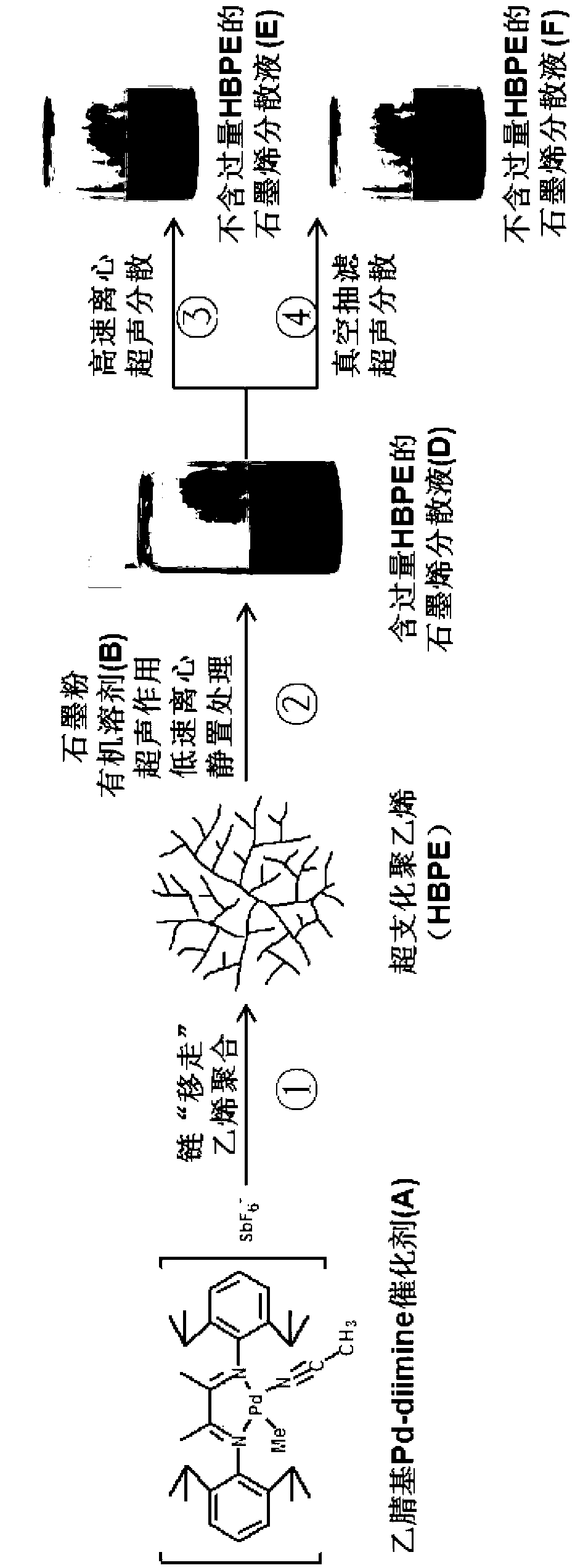

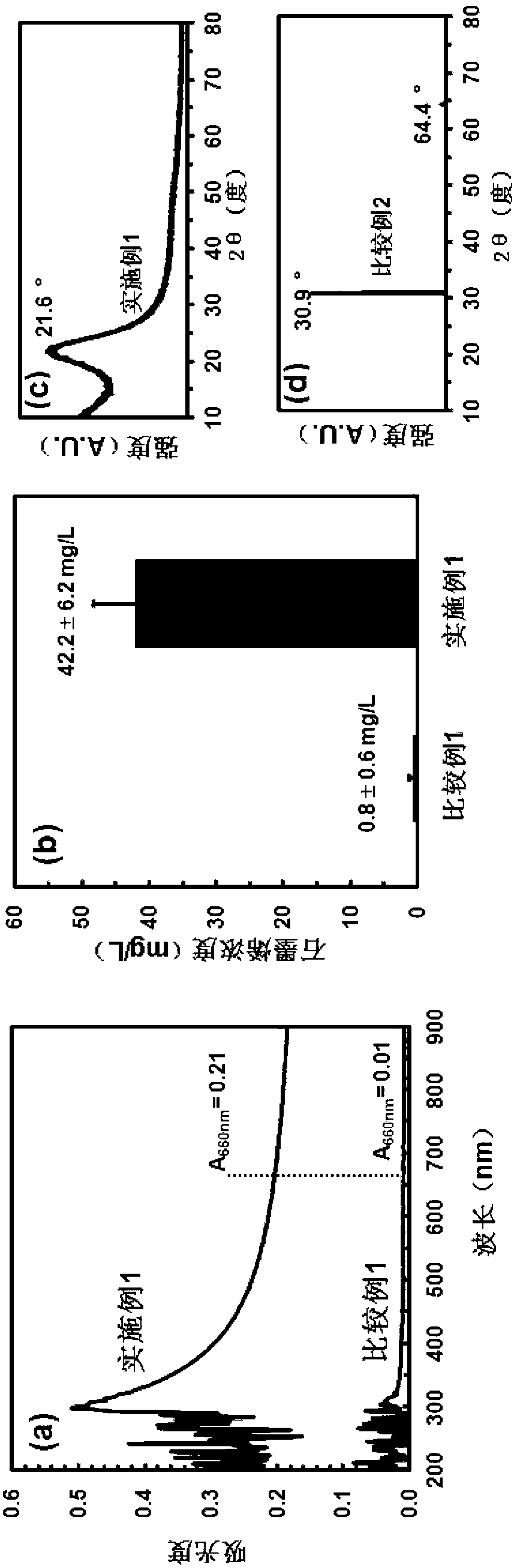

[0048] Embodiment 1, comparative example 1~2

[0049] 1. Sample preparation

[0050] (1) The preparation of the sample of Example 1 is carried out according to the following steps:

[0051] Step 1: Under the protection of ethylene, inject 100 mL of anhydrous dichloromethane into a 250 mL Schlenk reaction flask, stir for 30 min to keep the temperature at 35 ° C; then add acetonitrile-based Pd-diimine catalyst A (0.2 g, dissolved in 10 mL of anhydrous dichloromethane in advance, with a concentration of 1.82 g / L based on the total reaction volume) under the protection of ethylene. At a constant polymerization temperature (35 ° C) Stir the above solution under ethylene pressure (1 atm) to continue the polymerization for 24 h, immediately add 0.5 mL triethylsilane (0.005 times the total volume of the polymerization reaction) to the product and stir for 1 h to terminate the polymerization. The obtained polymeric product was purified as follows: firstly, the solvent was removed by...

Embodiment 2、 comparative example 2~3

[0068] 1. Sample preparation

[0069] (1) The preparation of the sample of Example 2 is carried out according to the following steps:

[0070] The 1st step: the synthesis technique of HBPE is the same as the 1st step in the embodiment 1.

[0071] Step 2: Add 500 mesh natural phosphorus flake graphite powder, chloroform and HBPE synthesized by the above step 1 into a 140 mL cylindrical glass bottle in sequence, and control the initial feeding ratio of each raw material as follows: The total volume of solvent is 100 mL, the initial concentration of graphite powder was 2 mg / mL, and the initial mass ratio of polymer / graphite powder was 2; ° C was continuously ultrasonicated for 48 h at constant temperature to obtain the initial dispersion of graphene. It was further centrifuged at a low speed (room temperature, 4000 rpm, 45 min), and after standing for 8 h, the centrifuged supernatant was collected, and finally a graphene dispersion containing excess HBPE was obtained.

[0072]...

Embodiment 3、 comparative example 2

[0086] 1. Sample preparation

[0087] (1) The preparation of the sample of Example 3 is carried out according to the following steps:

[0088] The 1st step: the synthesis of HBPE is with the 1st step in embodiment 1;

[0089] Step 2: Add 500-mesh natural phosphorus flake graphite powder, THF and HBPE synthesized by the above-mentioned step 1 into a glass container of 250 mL in order, and control the initial feeding ratio of each raw material as follows: the total volume of solvent is 150 mL, graphite The initial concentration of powder was 3 mg / mL, and the initial mass ratio of polymer / graphite powder was 2; ° C was continuously ultrasonicated for 112 h at a constant temperature to obtain the initial dispersion of graphene. It was further centrifuged at a low speed (room temperature, 4000 rpm, 45 min), and after standing for 8 h, the centrifuged supernatant was collected, and finally a graphene dispersion containing excess HBPE was obtained.

[0090] Step 3: Ultra-high-spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com