Method for preparing and separating enkaurane-16-alkene-19-acid from wedelia trilobata

A technology of Wedaria trilobata and kaurine, which is applied in the field of extracting active ingredients from medicinal plants, can solve the problems of inability to meet market demands, long production process cycle, unfavorable large-scale production, etc., and achieves easy control of operating parameters and effective ingredients. Highly enriched, impurity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

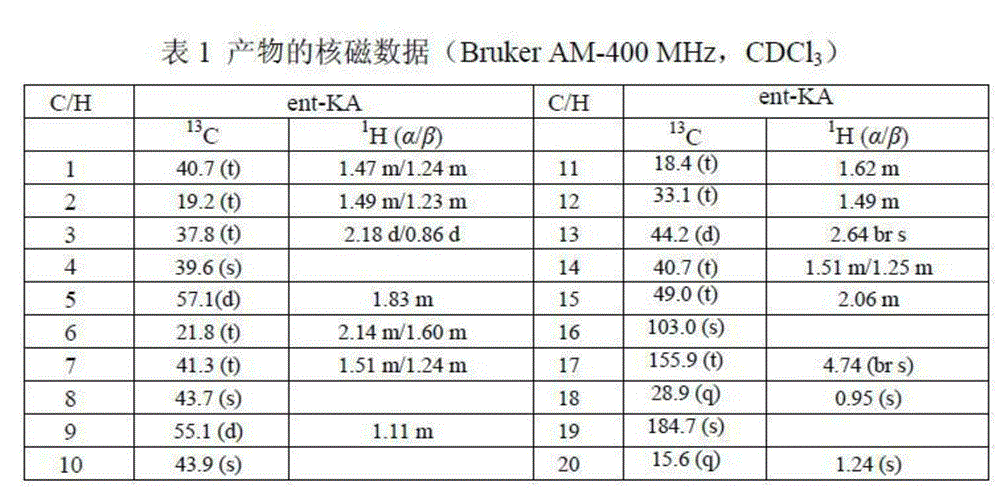

Examples

Embodiment 1

[0018] Dry Wedelia trilobata, pulverize, pass through a 30-mesh sieve, weigh 200 g of Wedelia trilobata powder and put it into the extraction kettle of a supercritical extractor (supercritical extractor: ISCO, USA, Model 260D, Syringe pump), entraining 60wt% ethanol was selected as the agent, the amount of entrainer added was 1200ml, and the flow rate of entrainer was 12ml / min; the extraction pressure was controlled at 25 MPa, the extraction temperature was 60°C, and the CO 2 The flow rate is 40L / h, and the extraction time is 3h; then concentrate under reduced pressure to remove ethanol to obtain about 40g of total extract, dissolve the total extract in 100ml of water, extract three times with 100ml of ethyl acetate, combine organic phases, and concentrate under reduced pressure to remove acetic acid Ethyl ester obtains about 20g of medicinal extract, 100g D101 type macroporous adsorption resin on the medicinal extract, elutes with 10L 60wt% ethanol aqueous solution, collects e...

Embodiment 2

[0020] Dry, grind, and pass through a 30-mesh sieve, weigh 250 g of Wedelia trilobata powder and put it into the extraction kettle of a supercritical extractor (supercritical extractor: ISCO, USA, Model 260D, Syringe pump), entraining The solvent used was 80 wt% ethanol, the amount of entrainer added was 1000ml, and the flow rate of entrainer was 10ml / min; the extraction pressure was controlled at 22 MPa, the extraction temperature was 50°C, and the CO 2 The flow rate is 35L / h, and the extraction time is 2.5h; then concentrate under reduced pressure to remove ethanol to obtain about 45g of total extract, dissolve the total extract in 150ml of water, extract three times with 150ml of ethyl acetate, combine the organic phase, and concentrate and remove the organic phase under reduced pressure Ethyl acetate obtains about 25g of medicinal extract, 200g D101 type macroporous adsorption resin on the medicinal extract, elutes with 10L 55wt% ethanol aqueous solution, collects eluent, c...

Embodiment 3

[0022] Dry, grind, and pass through a 30-mesh sieve, weigh 300 g of Wedelia trilobata powder and put it into the extraction kettle of a supercritical extractor (supercritical extractor: ISCO, USA, Model 260D, Syringe pump), entraining The solvent used was 95 wt% ethanol, the amount of entrainer added was 1200ml, and the flow rate of entrainer was 10ml / min; the extraction pressure was controlled at 20 MPa, the extraction temperature was 40°C, and the CO 2 The flow rate is 30L / h, and the extraction time is 2h; then concentrate under reduced pressure to remove ethanol to obtain about 50g of total extract, dissolve the total extract in 200ml of water, extract three times with 200ml of ethyl acetate, combine organic phases, and concentrate under reduced pressure to remove acetic acid Ethyl ester obtains about 30g of medicinal extract, 300g D101 type macroporous adsorption resin on the medicinal extract, elutes with 10L 50wt% ethanol aqueous solution, collects eluate, concentrates un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com