Single-walled carbon nanotube array with chiral selective orientation and method for representing chiral structure thereof

A single-walled carbon nanotube, selective technology, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems of high instrument cost, harsh operating conditions, complicated sample preparation process, etc., to achieve low cost, easy operation The effect of simplicity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

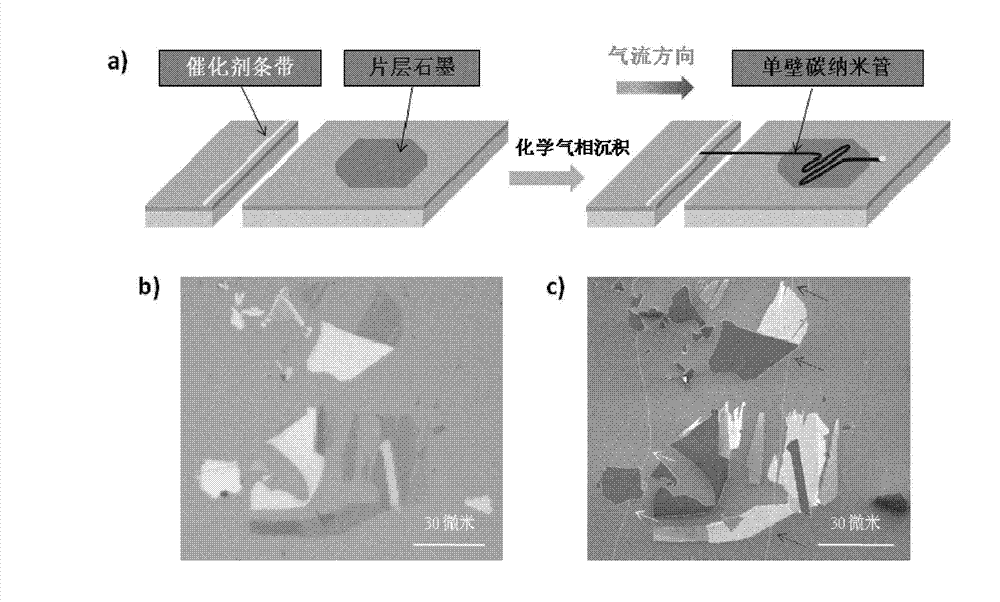

[0039] Example 1. Preparation of single-walled carbon nanotube arrays with chiral selective orientation on graphite surface

[0040] 1) Cleaning of the substrate: Select a Si single crystal with a 300nm oxide layer on the surface as the substrate for carbon nanotube growth, cut it into a size of 1cm×1cm; ultrasonically clean it in ultrapure water, acetone, ethanol and ultrapure water for 10min , and then blow dry with high-purity nitrogen for later use.

[0041] 2) Select kish graphite as raw material, use Scotch Tape to mechanically peel off different layers of graphite on the surface of Si substrate, use an optical microscope to determine the number and position of graphite layers, and spin-coat 0.1mmol / L FeCl on the surface of the substrate 3 / EtOH solution, the rotation speed is 3000rpm. Use the microcontact printing method to draw 0.1mmol FeCl on the edge pattern of another Si substrate with a 300nm oxide layer 3 / EtOH catalyst strips for the preparation of single-walle...

Embodiment 2

[0045] Embodiment 2, measuring the chiral angle of single-walled carbon nanotubes

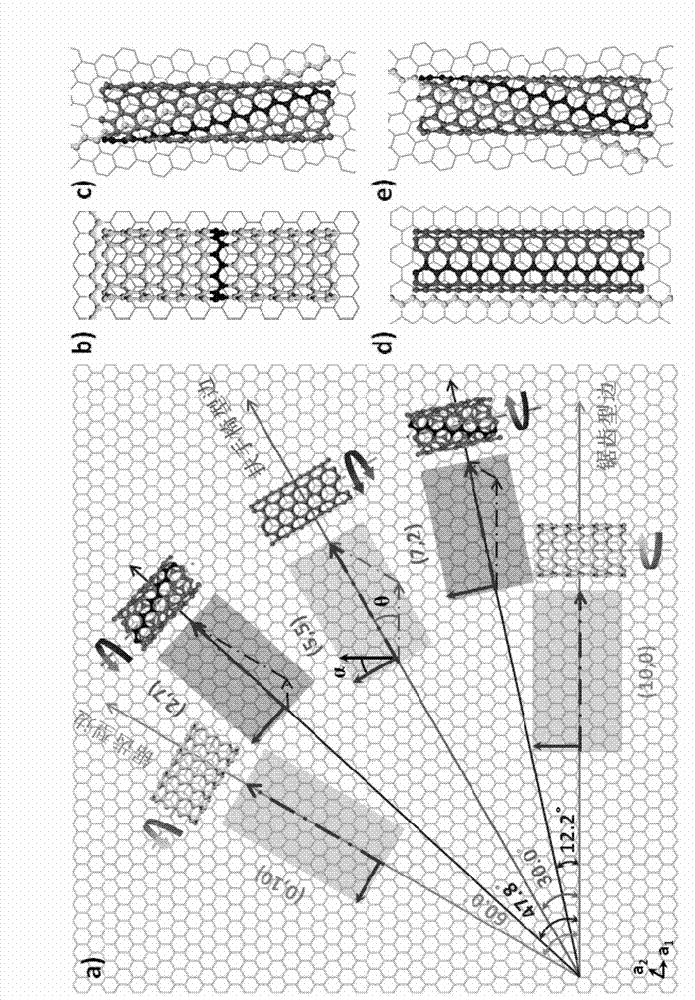

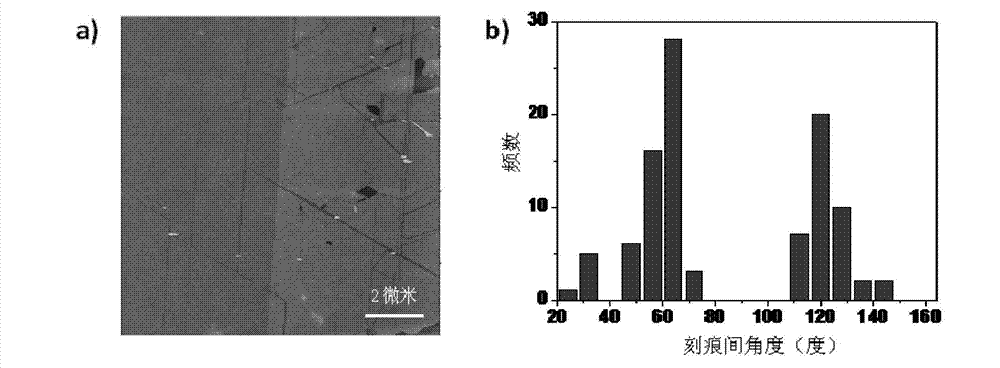

[0046] The chiral angle of the single-walled carbon nanotubes with chiral selective orientation prepared in Example 1 is measured, and the chiral angle θ of the carbon nanotubes is the angle between the curl vector direction of graphite and the zigzag direction. like Image 6 a indicates that the axial and radial directions of carbon nanotubes are perpendicular to each other, and the zigzag direction of graphite is perpendicular to the armchair direction. Therefore, the chiral angle of carbon nanotubes is the angle between the axial direction of carbon nanotubes and the edge of graphite armchair. Therefore, if the angle between the graphite indentation and the carbon nanotube axis is for Then the chiral angle θ of the carbon nanotube is If the angle between the graphite notch and the carbon nanotube axis for Then the chiral angle θ of the carbon nanotube is

[0047] In the above ...

Embodiment 3

[0049] Embodiment 3, measuring the optical activity of single-walled carbon nanotubes

[0050] The optical rotation of the single-walled carbon nanotubes with chiral selective orientation prepared in Example 1 was measured. Carbon nanotubes can be divided into right-handed and left-handed according to the size of the chiral angle or the direction of the curl vector (referring to the zigzag edge of graphite), and the chiral angle θ of the right-handed carbon nanotubes is 0°≤θ≤30° , the chiral angle θ of the left-handed carbon nanotube is 30°≤θ≤60°.

[0051] In the above method, the carbon nanotubes have chiral selective orientation on the graphite surface. The optical rotation of carbon nanotubes can be determined according to the relative angle between the axial direction of carbon nanotubes and the notch of graphite, such as Image 6 As shown in b, the angle between the carbon nanotube axis and the graphite notch for Then carbon nanotubes are right-handed; Image 6 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com