Multifunctional thermal container

A thermal insulation box and multifunctional technology, applied in the field of thermal insulation boxes, can solve the problems of poor sealing between the inner tank and the outer shell, the heating temperature cannot be too high, the heating speed is slow, etc. Rapid, usability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

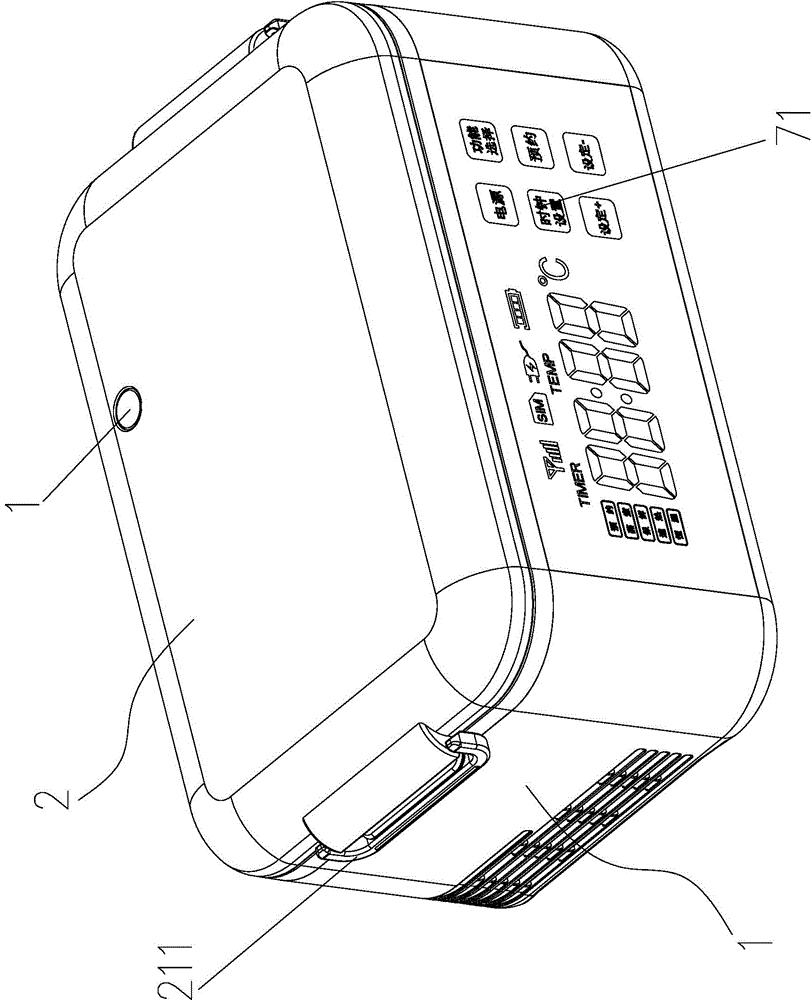

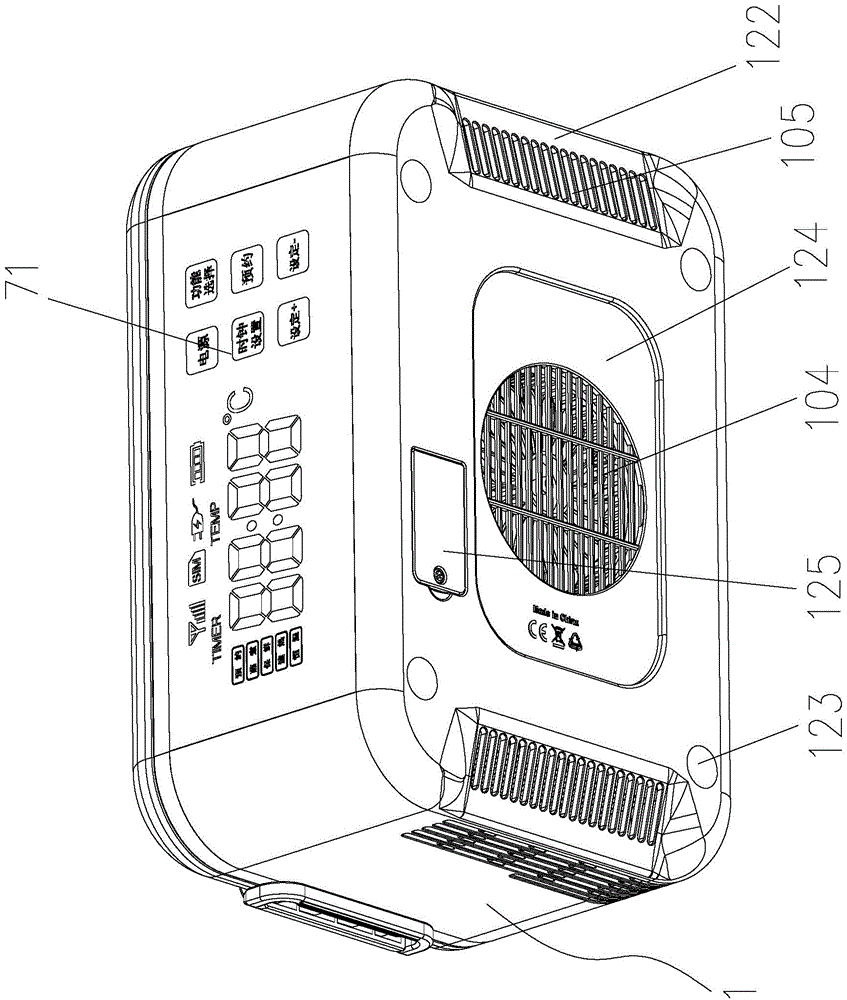

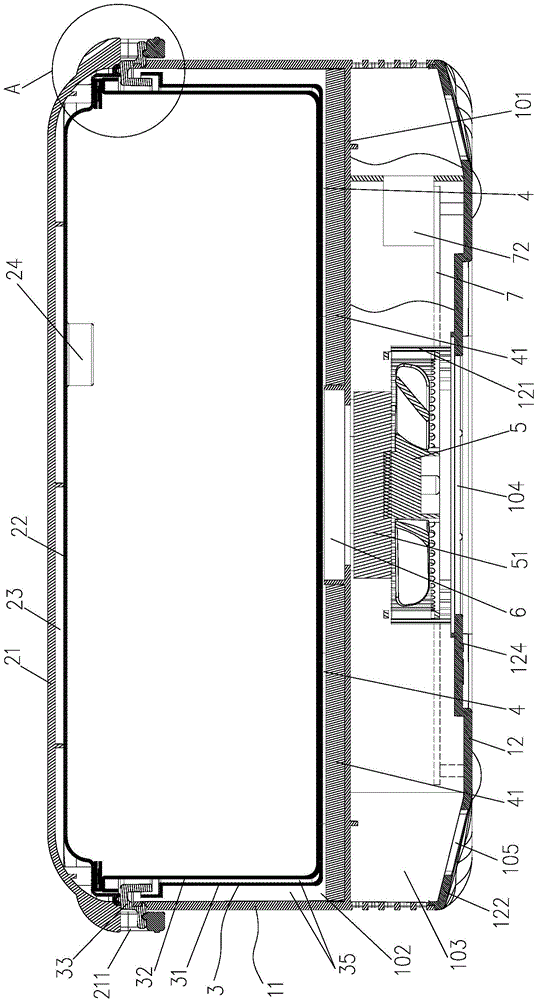

[0024] Such as figure 1 , figure 2 As shown, a kind of multifunctional heat preservation box of the present invention comprises a box body 1 and a cover body 2, wherein:

[0025] A horizontal partition 101 is formed in the box body 1 and the box body 1 is divided into an upper chamber 102 and a lower chamber 103, and a metal box 3 is arranged above the horizontal partition 101, that is, in the upper chamber 102, The bottom of the metal box 3 is in contact with the heating element 4 installed on the horizontal partition 101, and a first thermal insulation layer 41 is provided between the heating element 4 and the horizontal partition 101;

[0026] Open a through hole 100 in the middle part of the horizontal partition 101;

[0027] A radiator fan 5 is installed below the horizontal partition 101, that is, in the middle of the lower chamber 103. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com