Automobile water storage tank, cooling system with the same and automobile with cooling system

A technology for automobile cooling and water storage tank, applied in the direction of cooling brakes, vehicle parts, brakes, etc., can solve problems such as hidden dangers, crowded and disadvantageous space at the bottom of the frame, and achieve the effect of avoiding fatigue stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

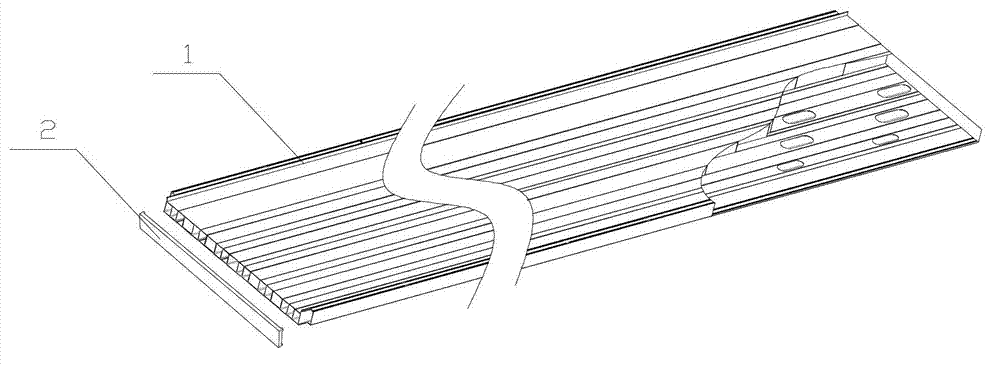

[0041] A water storage tank for a vehicle cooling system, comprising a water storage tank body 1, the water storage tank body is a

[0042] The body floor or a part of the body floor. Use the water storage tank as part of the bottom of the tank or as a tank

[0043] body bottom plate, avoiding the action of the water storage tank on the girder, especially concentrated action on a certain point of the girder, thereby avoiding

[0044] Avoid fatigue stress.

Embodiment 2

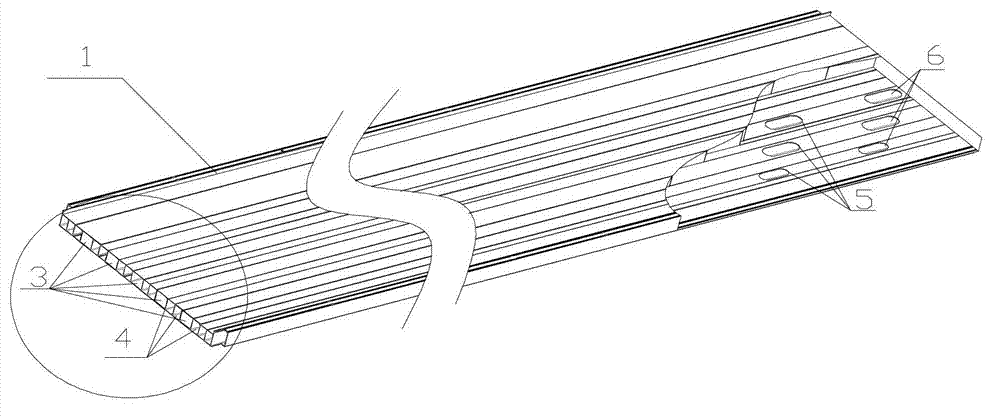

[0046] A water storage tank for a vehicle cooling system, comprising a water storage tank body 1, the water storage tank body is a

[0047] The body floor or a part of the body floor. Use the water storage tank as part of the bottom of the tank or as a tank

[0048] body bottom plate, avoiding the action of the water storage tank on the girder, especially on a certain point of the girder, thereby avoiding

[0049] produce fatigue stress. The water storage tank body includes at least one closed cavity 3 that is sealed around and at least one

[0050] A semi-closed cavity 4 with an opening at one end, the closed cavity is used for water storage, and the semi-closed cavity is used for fixing the water storage tank,

[0051] There is a fixed connection between the closed oral cavity and the semi-closed cavity. Closed cavities and semi-closed cavities can be a

[0052] Body formed, can also be welded to form.

Embodiment 3

[0054] A water storage tank for a vehicle cooling system, comprising a water storage tank body 1, the water storage tank body is a

[0055] The body floor or a part of the body floor. Use the water storage tank as part of the bottom of the tank or as a tank

[0056] body bottom plate, avoiding the action of the water storage tank on the girder, especially on a certain point of the girder, thereby avoiding

[0057] produce fatigue stress. The water storage tank body includes at least one closed cavity 3 that is sealed around and at least one

[0058] A semi-closed cavity 4 with an opening at one end, the closed cavity is used for water storage, and the semi-closed cavity is used for fixing the water storage tank,

[0059] There is a fixed connection between the closed oral cavity and the semi-closed cavity. Closed cavities and semi-closed cavities can be a

[0060] Body formed, can also be welded to form. The closed cavities are distributed axially symmetrically. closed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com