Vacuum pump for vehicle motors and one-way valve for said vacuum pump

A technology of vacuum pumps and check valves, applied in parts of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump parts, pumps, etc., to prevent fatigue stress, regular power absorption results, and power absorption The result is more effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

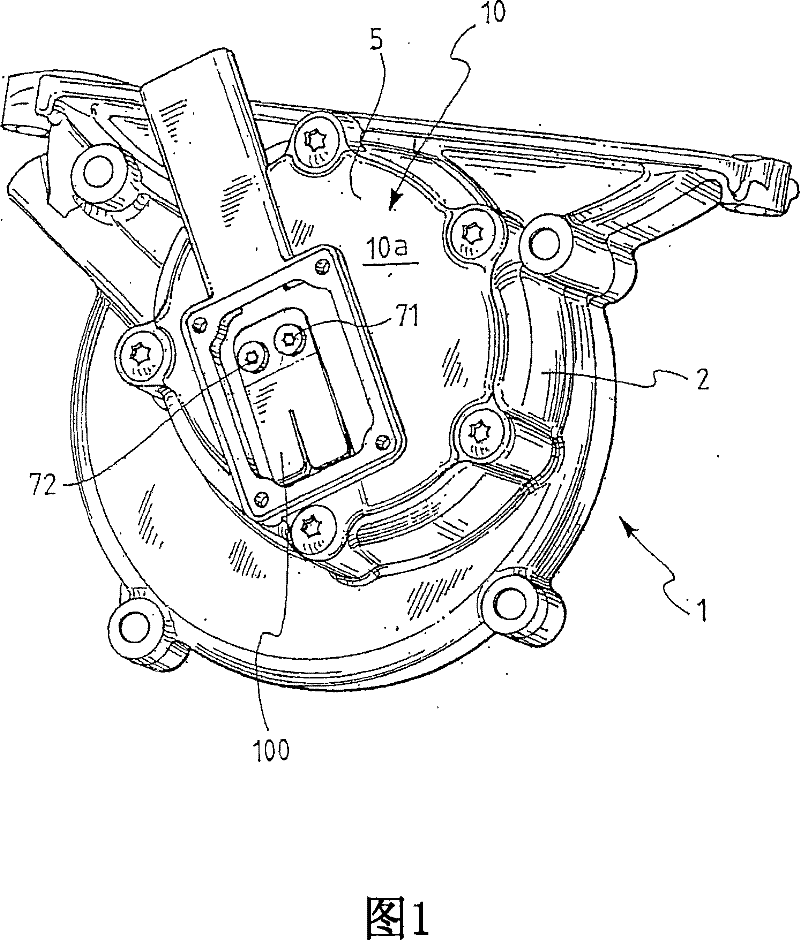

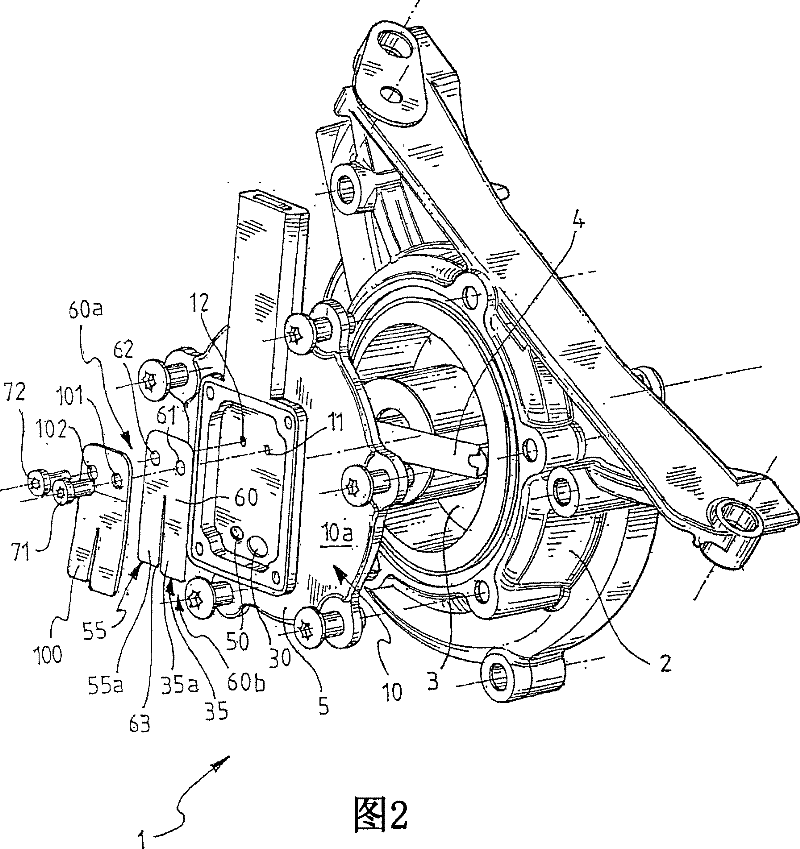

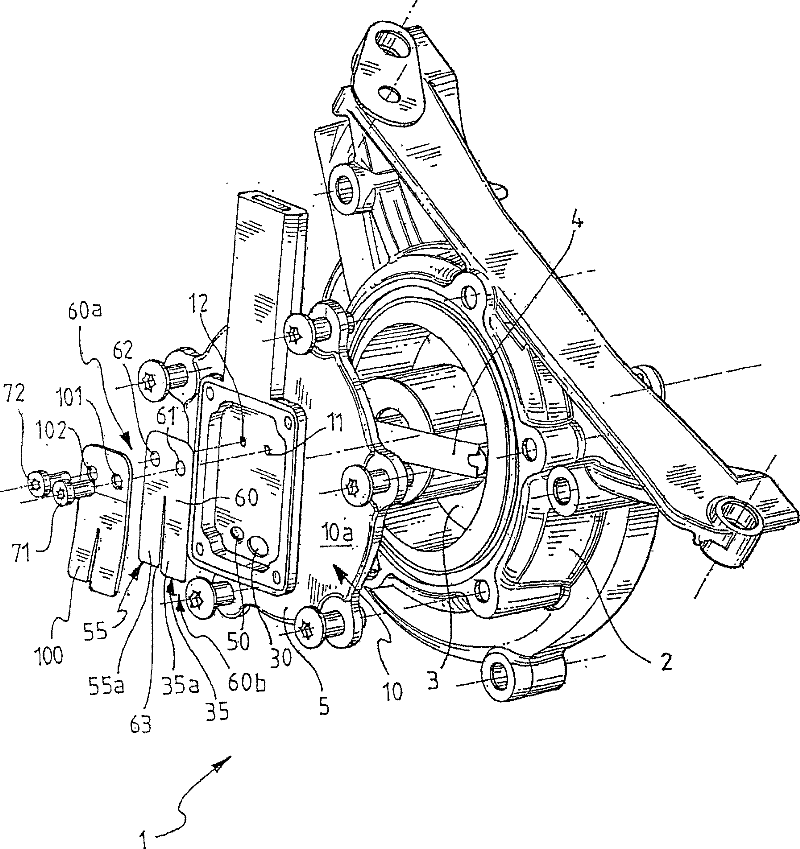

[0045] In the figures, a vacuum pump according to the invention is indicated with reference number 1 .

[0046] The vacuum pump 1 includes a stator 2, a chamber 3 is defined in the stator 2, and vanes 4 are rotatably installed in the chamber 3 ( figure 2 ). The vanes 4 are provided with opposite ends in sealing contact with the inner surface of the stator 2 to generate the desired low pressure.

[0047] The stator 2 comprises openings for the entry of air and oil (not shown as this is conventional per se and / or available in any convenient way to a person skilled in the art) and a closure cover 5 . From figure 2 It can be seen that, in the particular example shown therein, a first discharge opening 30 and a second discharge opening 50 are formed on the side surface 10 of the stator 2 defined by the cover 5 . The two discharge openings 30 and 50 are formed adjacent to each other and are different in size. Specifically, the first discharge opening 30 is larger in size than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com