Injection-molding mold-filling flow system for visualizing polymer melt

A flow system and polymer technology, which is applied in the field of visualization of polymer melt filling flow system, can solve the problems of inability to observe the motion state of fine and heterogeneous particles, low mold service life, and high operating costs, and achieve low construction and operating costs. , compact structure, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

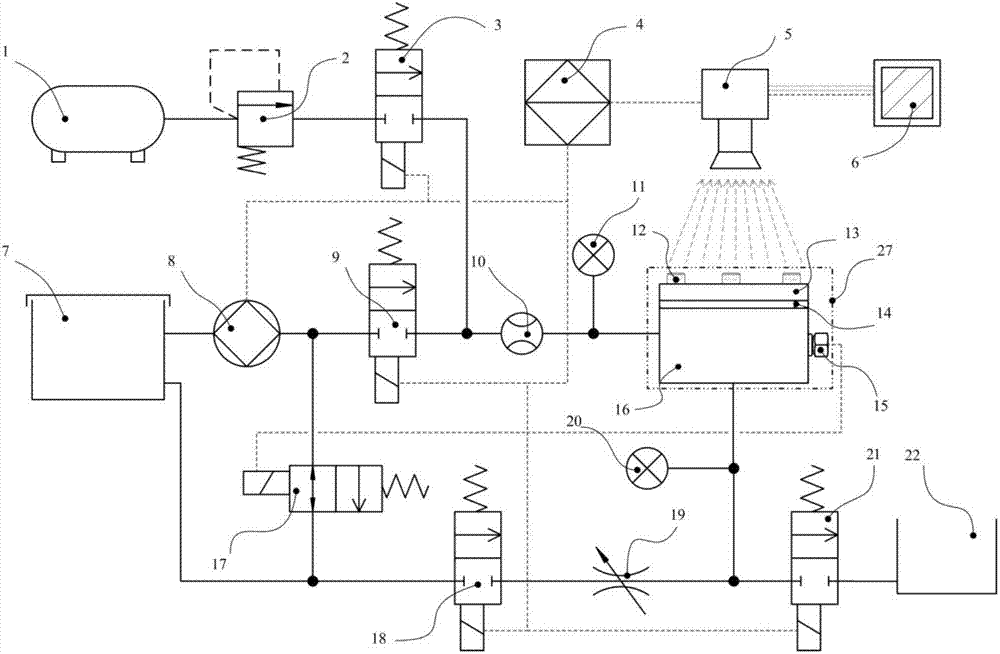

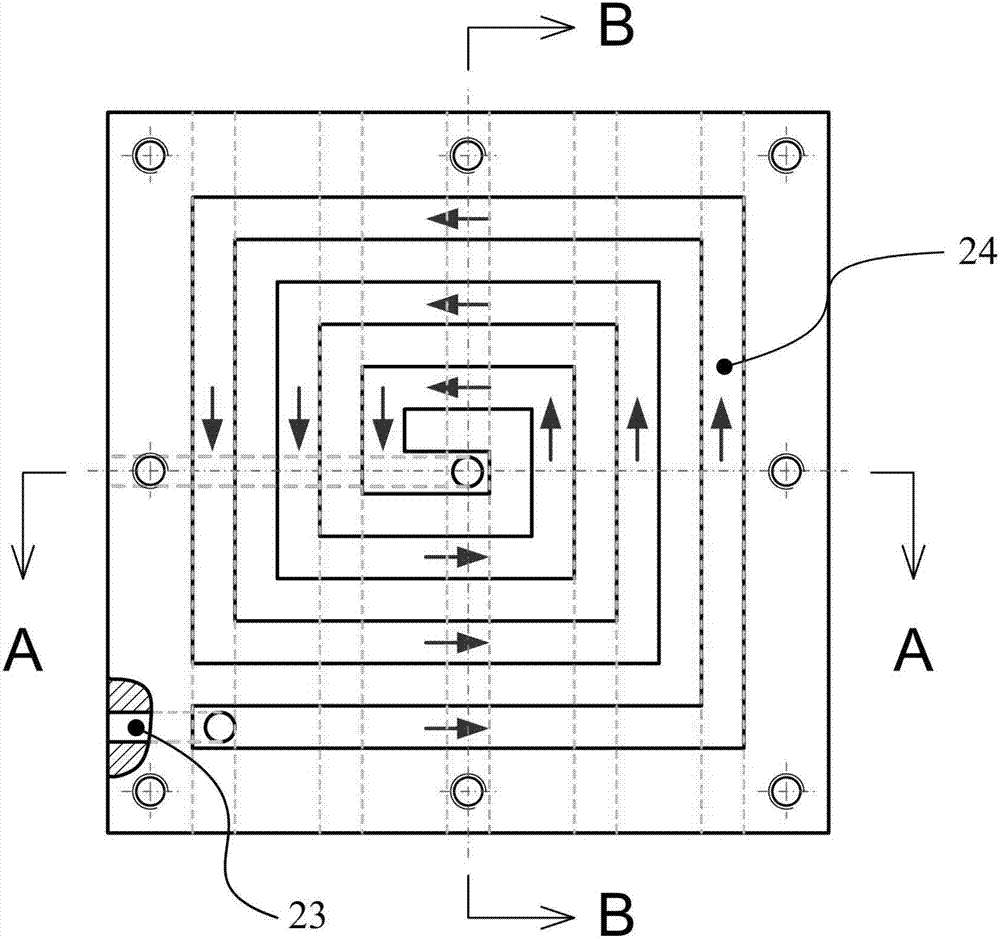

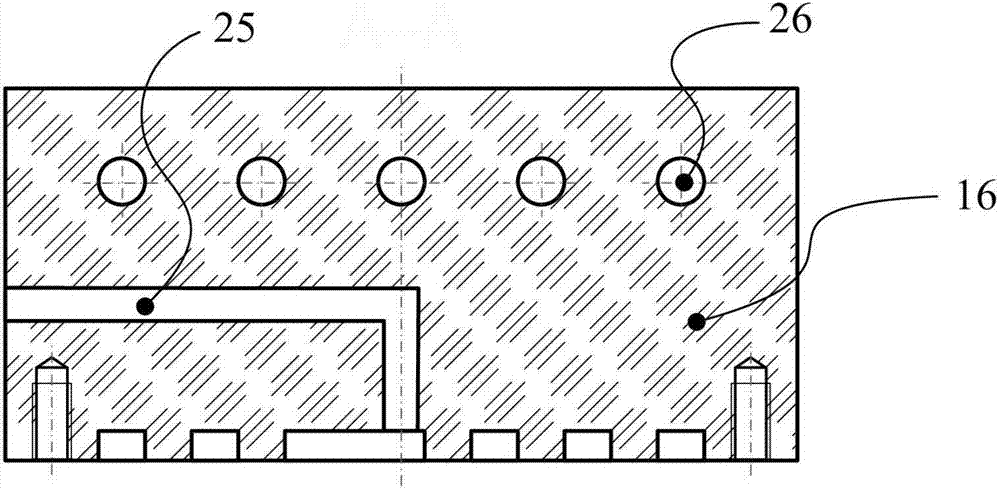

[0023] Such as figure 1As shown, a visual polymer melt injection mold filling flow system includes two closed-loop circuits, wherein the first circuit includes a closed container 7 connected in sequence, an adjustable flow pump 8, a first reversing valve 9, a flow rate Gauge 10, inlet pressure gauge 11, transparent mold tooling 27, outlet pressure gauge 20, throttle valve 19, second reversing valve 18, airtight container 7, the second loop includes airtight container 7 connected in sequence, adjustable flow pump 8. The third reversing valve 17 and the airtight container 7.

[0024] The visualized polymer melt injection molding filling flow system also includes a residue discharge and residual material recovery system. The residue discharge and residual material recovery system includes a high-pressure gas source 1, a pressure regulating valve 2, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com