A solid propellant flame splitting device

A solid propellant and flame technology, which is used in measuring devices, material analysis and material analysis by optical means, etc., can solve the problem of inability to observe the movement process of metal particles in the flame, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

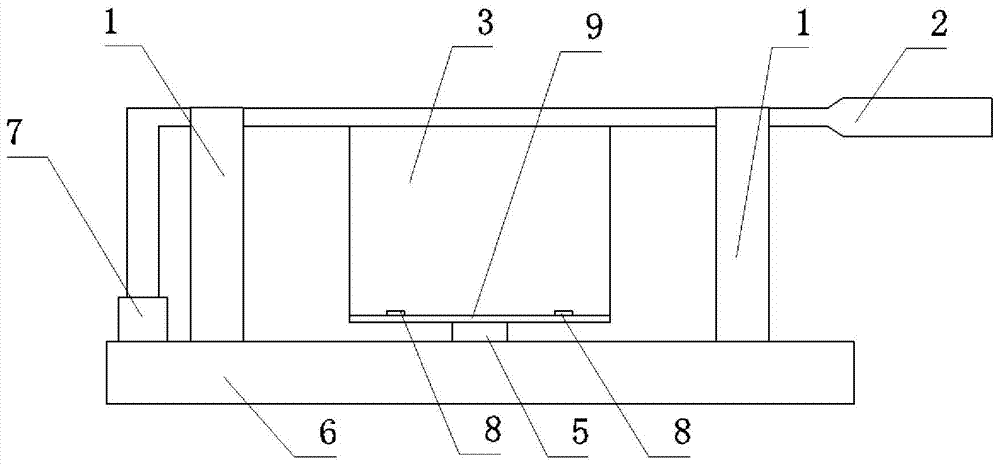

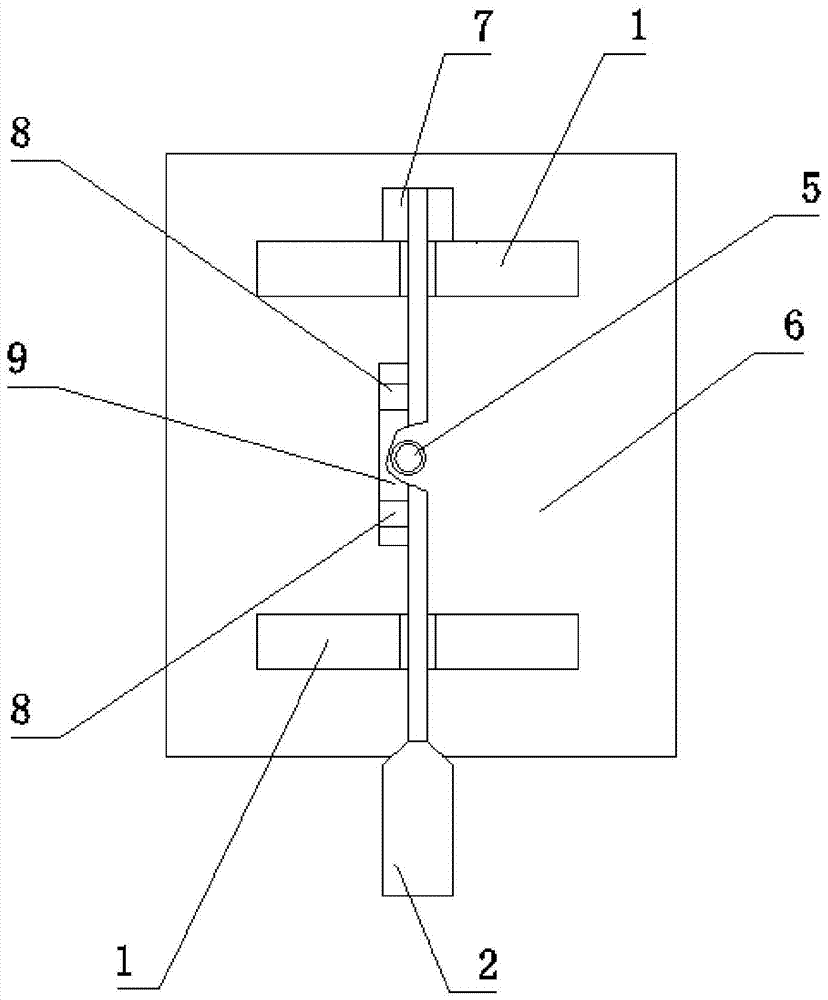

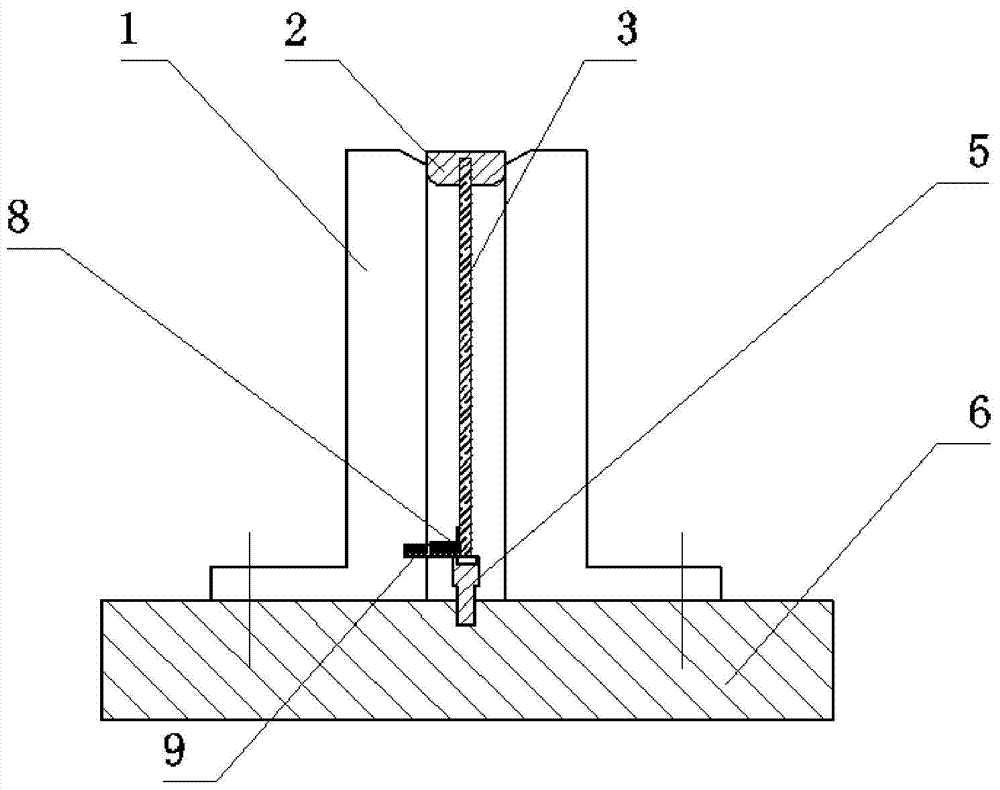

[0020] A solid propellant flame splitting device, comprising a directional support 1, a bracket 2, a quartz glass plate 3, a solid propellant support 5, a base 6, a rotating shaft support 7, a connecting block 8 and an ignition plate 9. The support 2 is L-shaped, and the vertical bar of the support 2 is rotatably connected with the rotating shaft support 7, so that the L-shaped support 2 can move up and down. The rotating shaft support 7 is welded on the base 6, the bottom of the cross bar of the support 2 has a first groove along the length direction, the quartz glass plate 3 is arranged in the first groove of the support 2, and the two ends are fixed by screws for easy disassembly and replacement. Set along the length of the bar. The solid propellant support 5 is threaded on the base 6 and is located below the center of the bottom edge of the quartz glass plate 3 . The fire pressing plate 9 is provided with 502 glue, and is fixedly connected with the bottom side of the quar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com