Method for machining molded line of scroll plate

A scroll and wire processing technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of reduced processing speed, low processing cost, and large memory space, so as to improve efficiency and save processing cost , the effect of prolonging the service life and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

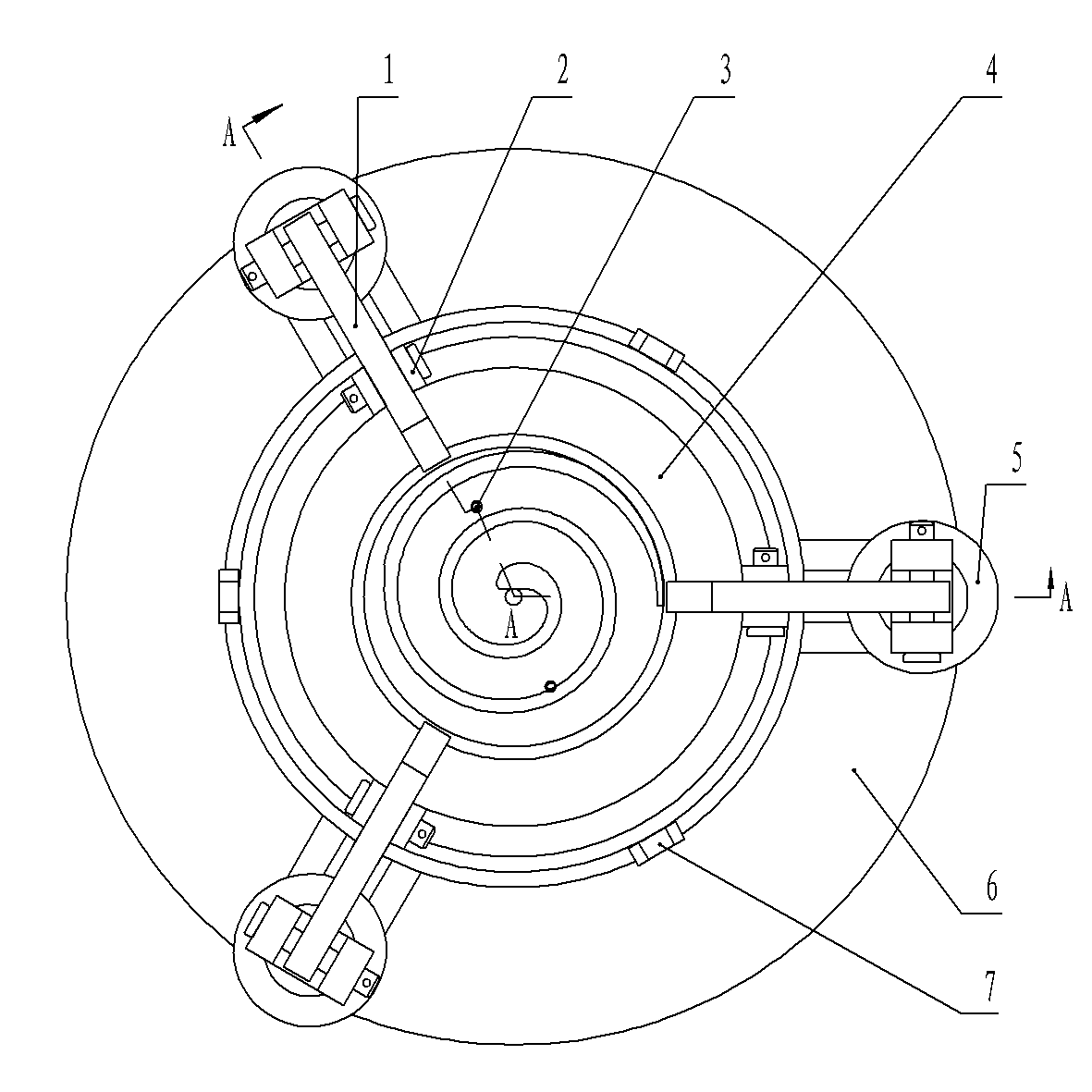

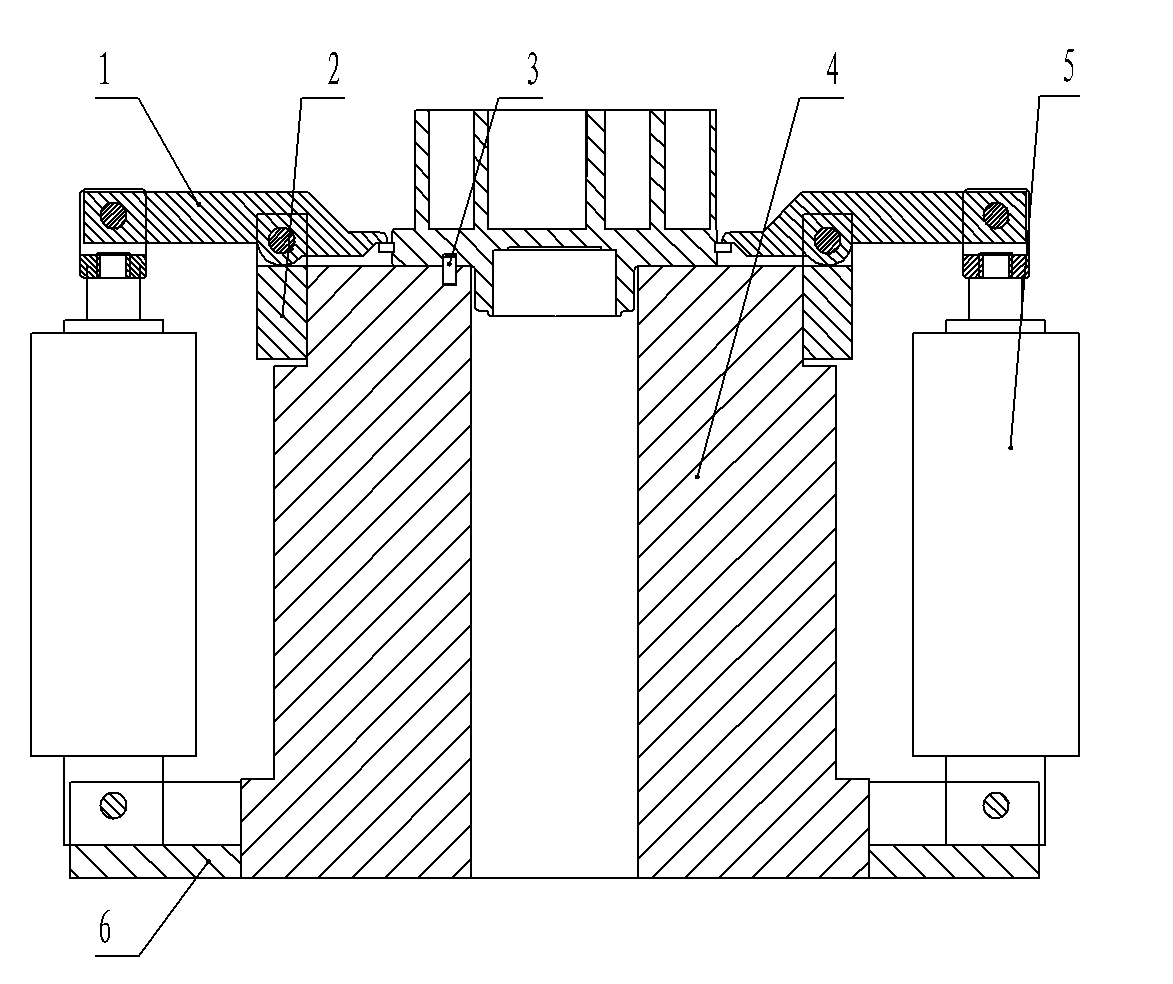

[0020] The scroll has an end plate and a scroll wall on it, and the lower end of the end plate is provided with a positioning hole; the method of processing the scroll profile is to use such as figure 1 , figure 2 The scroll profile processing jig shown, the scroll profile processing fixture includes a base 4 with a middle hole on the top surface, the bottom of the base 4 is fixedly connected with a lower end plate 6, in the middle of the top surface of the base There are three pressing arms 1 distributed around the hole, and these three pressing arms 1 are hinged on the base 4 through hinge shafts, each pressing arm 1 is respectively hinged with a pressing arm driving cylinder 5, and the top surface of the base 4 is equipped with two positioning pin 3;

[0021] The operation steps include:

[0022] Install the fixture first: fix the lower end plate 6 of the scrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com