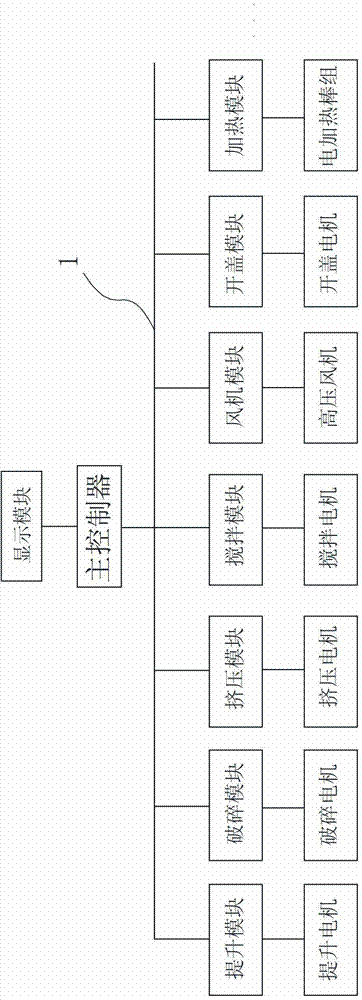

Electrification control system of kitchen waste disposer

A kitchen waste and control system technology, applied in the direction of solid waste removal, etc., can solve the problems of inability to meet the centralized treatment and electrification control of kitchen waste, unable to form a waste treatment process, and simple electrification control, etc., to improve reliability. and error detection ability, shorten the development cycle, improve the effect of anti-interference degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

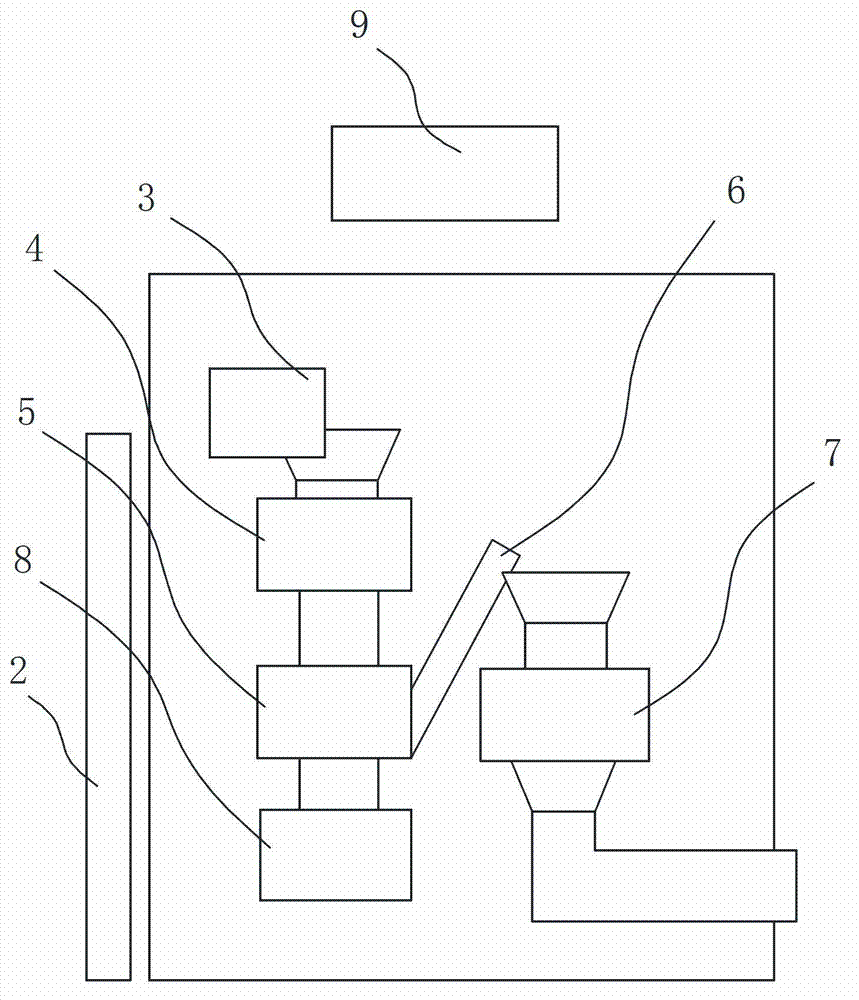

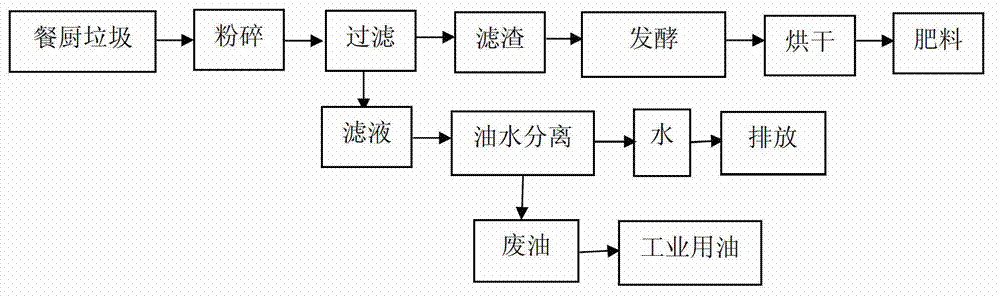

[0038] Food waste generally undergoes treatment processes such as crushing, solid-liquid separation, extrusion, fermentation and drying, and oil-water separation. The solid food waste after the above treatment can be used as fertilizer, and the waste water extracted from liquid food waste can be used as fertilizer. The waste oil can be directly discharged, and the waste oil can be used as a raw material for refining industrial oil. However, the existing food waste treatment methods are relatively simple, and there is no special food waste disposer, which can perform centralized and complete treatment of the entire food waste. In addition, the existing food waste disposer is electrified The control is simple, and most of them rely on on-site wiring to complete the wiring operation of each electrical control component. The wiring layout is cumbers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com