Non-woven fabric and method for producing non-woven fabric

A manufacturing method and technology of non-woven fabrics, applied in the direction of textiles and papermaking, non-woven fabrics, fabric elongation, etc., can solve the problem of non-woven fabric breaking strength, non-woven fabric damage, and manufacturing speed that are difficult to reduce fluffed non-woven fabrics Slow and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

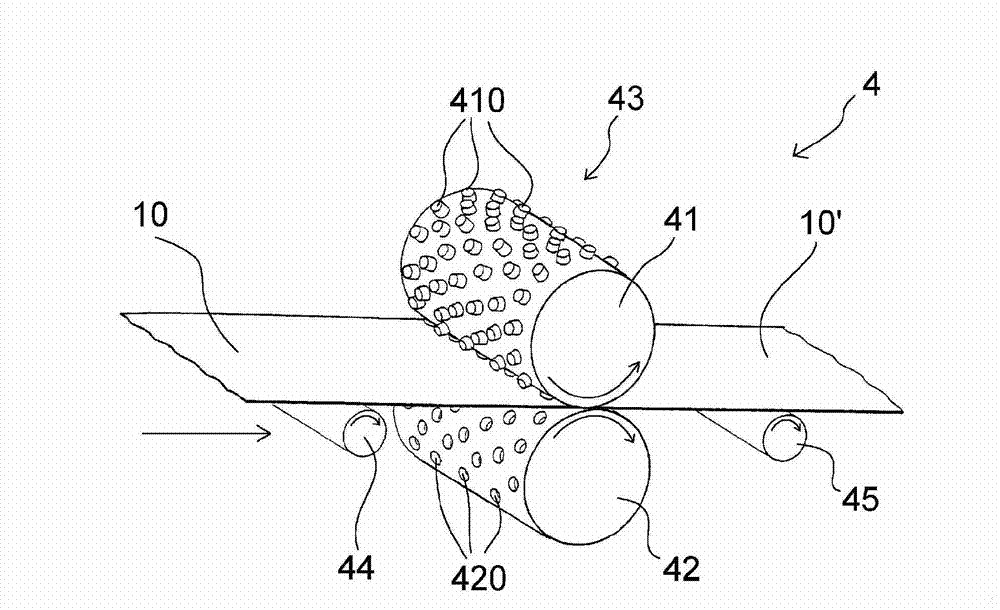

[0167] Using a spunbonded layer made of ethylene-propylene copolymer resin with a fiber diameter of 14.7 μm, the grammage per square meter is 15 g / m 2 (Spunbond-meltblown-spunbond laminated nonwoven fabric, hereinafter also referred to as SMS) (the nonwoven fabric in this state is referred to as Comparative Example 5). Next, pass the SMS non-woven fabric through the image 3 Matching embossing steel roll 43 indicated in Figure 4 The convex roller 51 shown in is subjected to surface processing, and a two-stage treatment is performed to obtain a nonwoven fabric. The height of each convex portion 410 in the roller 41 of the matching embossing steel roller 43 used is 2.8mm, and the engagement depth between each convex portion 410 of the roller 41 and each concave portion 420 of the roller 42 is 2.7mm. In addition, the distance (gap) between the protrusions 410 adjacent to each other in the rotation axis direction was 7 mm, and the distance (gap) between the protrusions 410 adja...

Embodiment 2

[0169] Using a spun-bonded layer made of acrylic resin with a fiber diameter of 17.7 μm, the grammage per square meter is 15 g / m 2 Non-woven fabrics (spunbond-meltblown-spunbond laminated nonwoven fabrics, hereinafter also referred to as SMS). Next, this SMS nonwoven fabric was subjected to two-step treatment under the same conditions as in Example 1 to obtain a nonwoven fabric.

Embodiment 3

[0171] Using a spunbond layer made of ethylene-propylene copolymer resin with a fiber diameter of 12.9 μm, the grammage per square meter is 18 g / m 2 (Spunbond-spunbond-meltblown-spunbond laminated nonwoven fabric, hereinafter also referred to as SSMS. Softeners are mixed into the spunbond layers on both sides of the SSMS nonwoven fabric). Next, this SSMS nonwoven fabric was subjected to two-stage treatment under the same conditions as in Example 1 to obtain a nonwoven fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com