Lockable button

A button and fixed part technology, applied in the field of buttons, can solve problems such as loss of accuracy, lack of smoothness and accuracy, deformation of grippers, etc., and achieve the effect of reduced manufacturing costs and smooth and reliable engagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

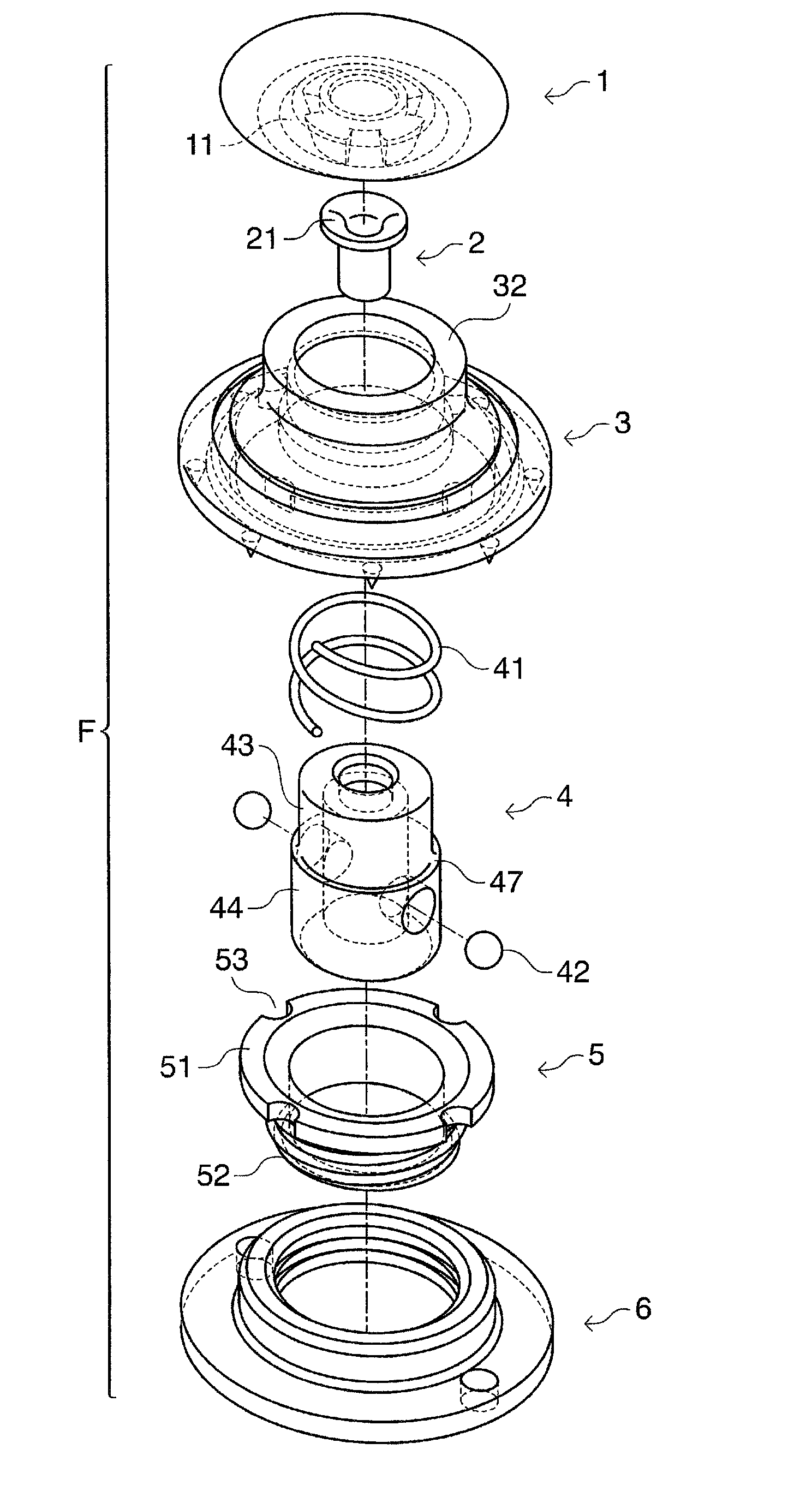

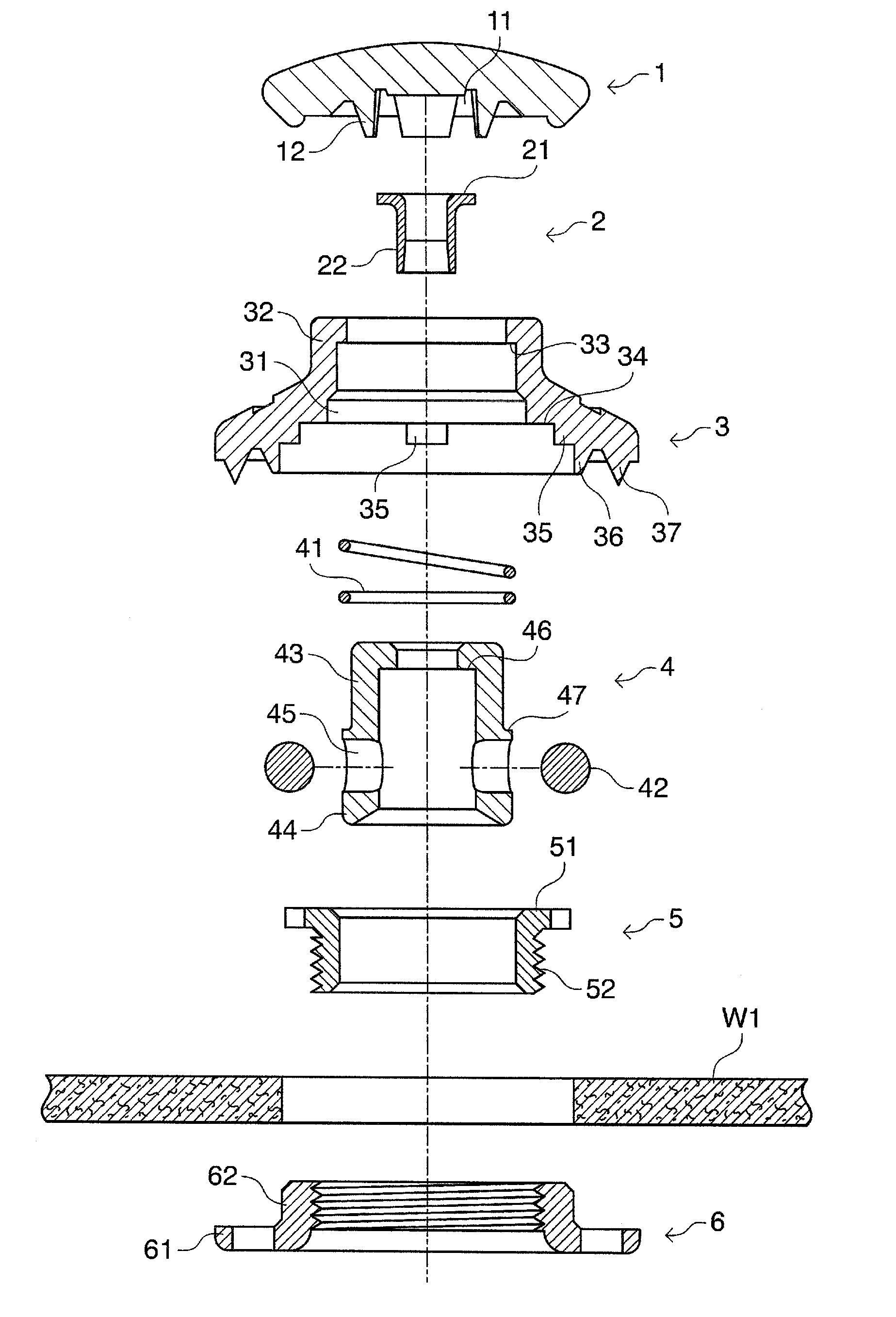

Image

Examples

Embodiment 2

[0054] Figure 7 ~ Figure 10It is the second embodiment of the present invention. The difference from the first embodiment is that no male screw is used in the female component F, and the frame body 3A and the back seat 6A are directly riveted by the pin 63 . For this reason, it is necessary to provide the extension part 38 in the frame body 3A in advance, to provide the through-hole 39 in the extension part 38, and to provide the opening part 64 also in the back seat 6A.

[0055] In addition, for the same components as those in the first embodiment, symbols in which "A" is added to the symbols used in the first embodiment are used, and descriptions thereof are omitted.

[0056] At this time, since the back seat 6A and the male screw 5A are recessed in a bowl shape toward the center core 4A, insertion and engagement can be performed even if the bead 7A of the male member is inclined.

[0057] In the present embodiment, the number of parts is 8 male members and 3 female membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com