Absolute-type grating control system and control method based on industrial Ethernet bus

A control method and control system technology, which is applied in the absolute grating control system and control field, can solve the problems of small amount of communication data, difficulty in realizing high-speed cross-communication of servo system data, inability to flexibly adapt to various grating devices, etc., to achieve High control performance to ensure effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

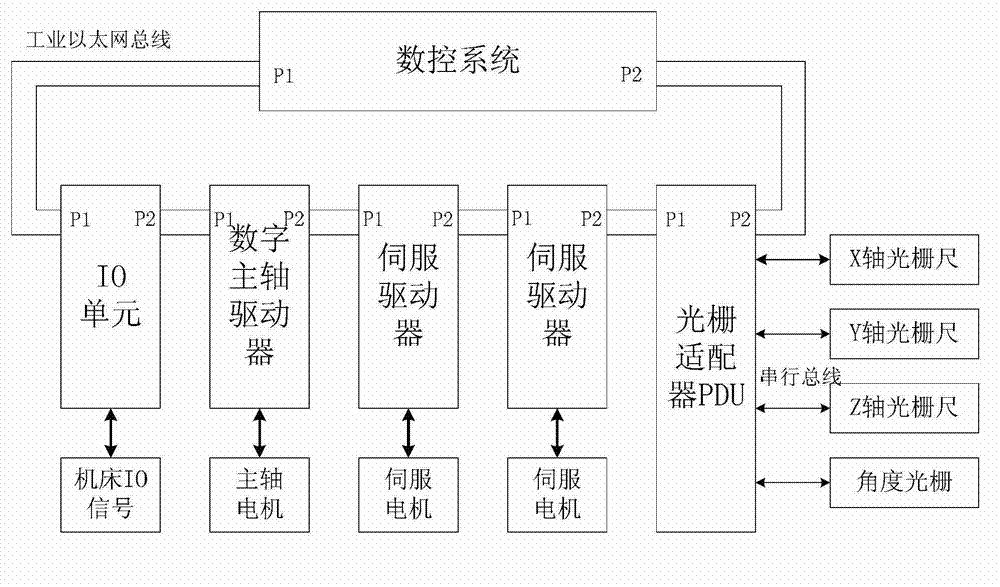

[0048] like figure 1 , figure 2 As shown, this embodiment is based on the absolute grating control system of the industrial Ethernet bus, and the numerical control system is connected to each slave station device in a ring topology through the industrial Ethernet bus. It is characterized in that the slave station includes sequentially connected IO units, digital spindles The drive, the feed axis drive and the grating adapter slave station PDU, the grating adapter slave station PDU is connected to the linear grating and angle grating.

[0049] The grating adapter slave station PDU includes FPGA main chip, serial memory EPCS and SDRAM memory, Ethernet physical chip and dual network interface, power conversion and grating device serial interface.

[0050] The FPGA main chip adopts the system-on-chip SOC technology, which can flexibly configure the software and hardware system framework. The hardware framework structure includes a soft-core main CPU, an internal RAM connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com