Organic rankine-type industrial waste heat integrated recovery device

An industrial waste heat recovery device technology, which is applied to steam engine devices, mechanical equipment, indirect heat exchangers, etc., can solve problems such as explosion of organic working fluid and leakage of heat exchangers, and improve safety performance, reduce low-temperature corrosion, and reduce emissions. Effect of Smoke Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

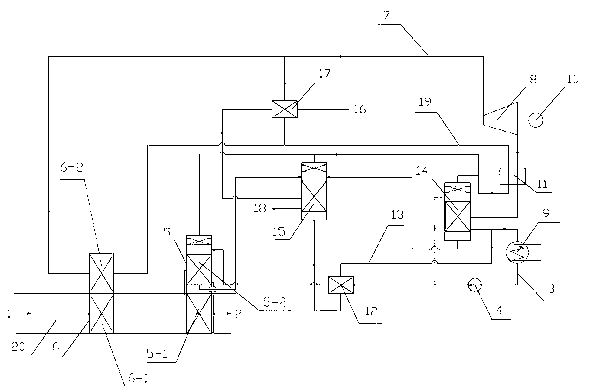

[0045] Such as figure 1 As shown, an organic Rankine type industrial waste heat integrated recovery device, the specific examples are as follows:

[0046] The high-temperature fluid 1 is the flue gas of the utility boiler, and the steam 16 is the waste steam generated by hydrophobicity, the exhaust steam of the deaerator, etc.;

[0047] Using multi-component organic working fluid;

[0048] Described organic Rankine cycle refers to that the organic liquid 3 passes through the condenser 5-2 of the circulating pump 4 and the cooling evaporator 5, and the organic working medium vapor generated passes through the organic working medium steam pipeline 19 and the phase change heat exchanger 6. The condenser 6-2 forms the superheated steam 7 of the organic working medium, which is sent to the steam turbine 8 to drive the generator 10 to generate electricity, and the lean liquid produced by the cooling evaporator 5 returns to the condenser 9 through the return line 13, and the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com