Sound absorption and vibration reduction polyester composite cotton and preparation method of sound absorption and vibration reduction polyester composite cotton

A technology of composite cotton and polyester, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems that the safety and environmental protection performance cannot meet the market requirements, achieve excellent thermal insulation performance, prolong the transmission path and time, and block thermal bridges Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the examples. The following examples are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

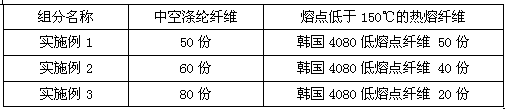

[0026] The mass parts of each component of the sound-absorbing and shock-absorbing polyester composite cotton provided in Examples 1-3 are shown in Table 1, and the preparation method is carried out according to the following steps:

[0027] 1. Weighing and feeding: Weigh hollow polyester fibers with a mass percentage of 50% to 80% and hot-melt fibers with a mass percentage of 20% to 50% whose melting point is lower than 150°C, and put them into the cotton blending and opening equipment. The fiber fineness of polyester fibers and hot-melt fibers with a melting point below 150°C is 3 deniers to 15 deniers;

[0028] 2. Cotton blending and opening: under the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com