Cement-emulsified asphalt mortar for slab tracks in severe cold areas

A technology of cement emulsified asphalt and emulsified asphalt, which is used in tracks, track maintenance, track laying and other directions, and can solve problems such as delamination, cracking and fragmentation of mortar cushions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this example and Examples 2-4 below, the emulsified asphalt contained in the cement-emulsified asphalt mortar of the present invention was prepared.

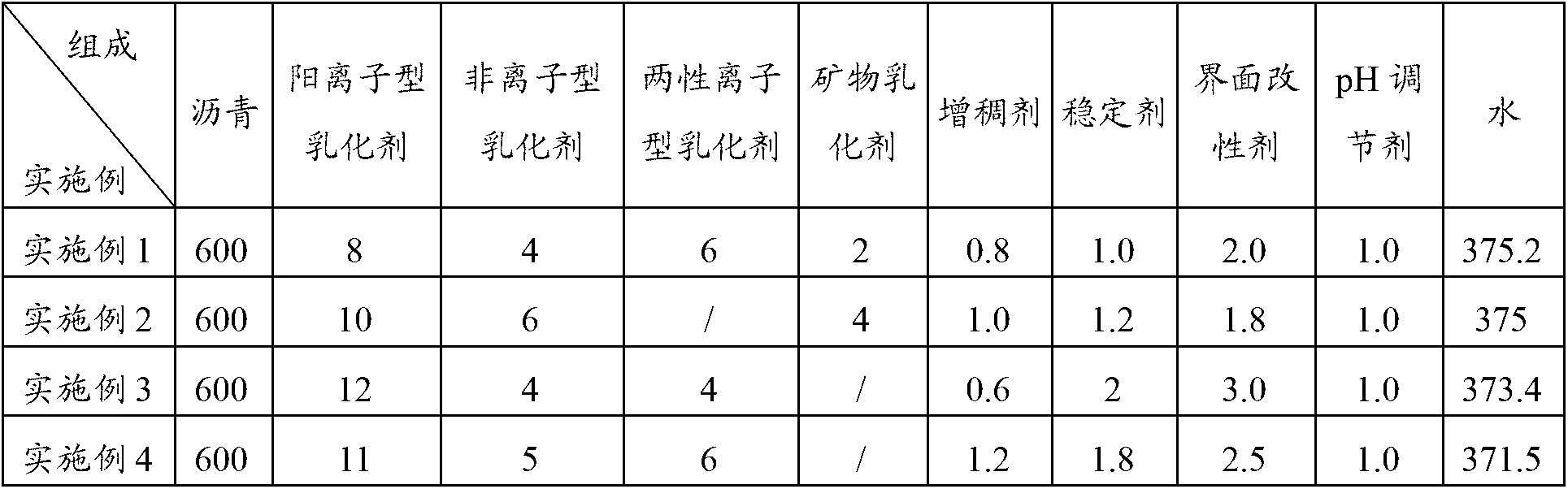

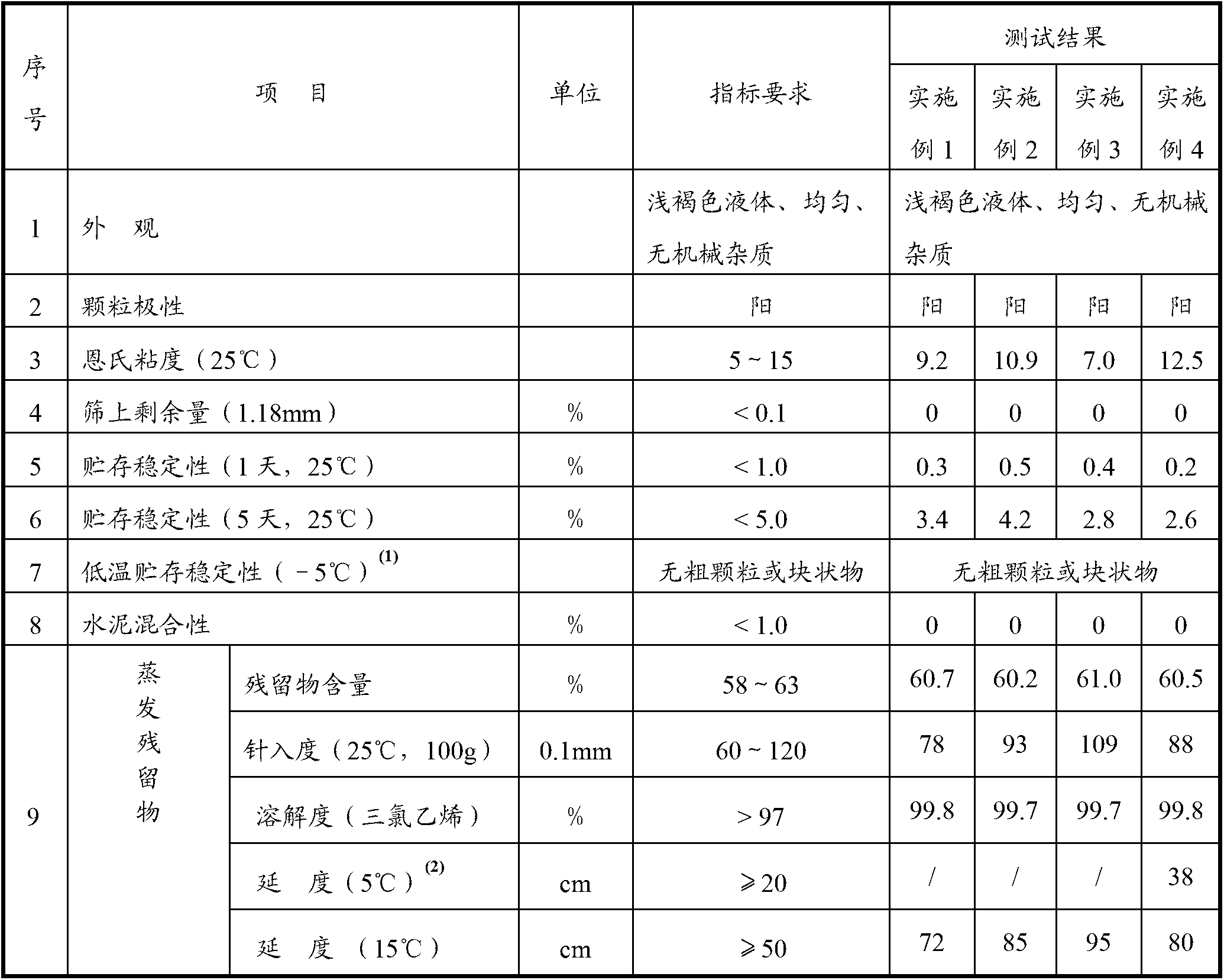

[0067]In this embodiment, the emulsified asphalt adopts 70# heavy traffic road petroleum asphalt, the cationic emulsifier is octadecyltrimethylammonium chloride, and the nonionic emulsifier is alkyl nonylphenol polyoxyethylene ether, polyoxyethylene polymerized Degree 30, zwitterionic emulsifier is cocamidopropyl betaine, mineral emulsifier is bentonite, thickener is cellulose ether (molecular weight 40000), stabilizer is calcium chloride, interface modifier is polycarboxylic acid With alkylamine, the pH regulator is hydrochloric acid, and its composition is shown in Table 1.

[0068] Preparation method of emulsified asphalt:

[0069] Dehydrate 70# heavy traffic road petroleum asphalt at 100°C, and then control the temperature of the asphalt at 120°C-130°C;

[0070] Add the emulsifier and thickener measured in propor...

Embodiment 2

[0075] In this embodiment, the emulsified asphalt adopts 90# heavy traffic road petroleum asphalt, the cationic emulsifier is bis-octyl / decyl dimethyl ammonium chloride and aminated lignin, and the nonionic emulsifier is fatty acid polyoxyethylene ester, thickening The agent is cellulose ether and polyurethane, the mineral emulsifier is bentonite, the stabilizer is sodium chloride, the interface modifier is Span 20 and polycarboxylic acid, and the pH regulator is hydrochloric acid. The composition is shown in Table 1.

[0076] Preparation method of emulsified asphalt:

[0077] Dehydrate 90# heavy traffic road petroleum asphalt at 100°C, and then control the temperature of the asphalt at 120°C-130°C;

[0078] Add the emulsifier and thickener measured in proportion to the water at 60°C, adjust the pH value of the solution to the specified value, and control the temperature of the emulsifier solution to 50°C-60°C;

[0079] Pour the measured emulsifier solution into the cleaned e...

Embodiment 3

[0083] In this embodiment, the emulsified asphalt adopts 110# heavy traffic road petroleum asphalt, the cationic emulsifier is octadecyl trimethylammonium chloride and octadecyl dimethyl propamide, and the nonionic emulsifier is polyoxyethylene Ether, polyoxyethylene polymerization degree 40, zwitterionic emulsifier is lauryl imidazoline betaine, thickener is polyether, stabilizer ammonium chloride and calcium chloride, interface modifier is polycarboxylic acid, pH regulator It is glacial acetic acid, and its composition is as shown in Table 1.

[0084] Preparation method of emulsified asphalt:

[0085] Dehydrate 110# heavy traffic road petroleum asphalt at 100°C, and then control the temperature of the asphalt at 120°C-130°C;

[0086] Add the emulsifier and thickener measured in proportion to the water at 60°C, then adjust the pH value of the solution to the specified value, and control the temperature of the emulsifier solution to 50°C-60°C;

[0087] Pour the measured emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com