Crystallizer for hydrolyzing carnallite

A technology of crystallizer and carnallite, which is applied in the field of salt chemical industry, can solve problems that cannot be solved, and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

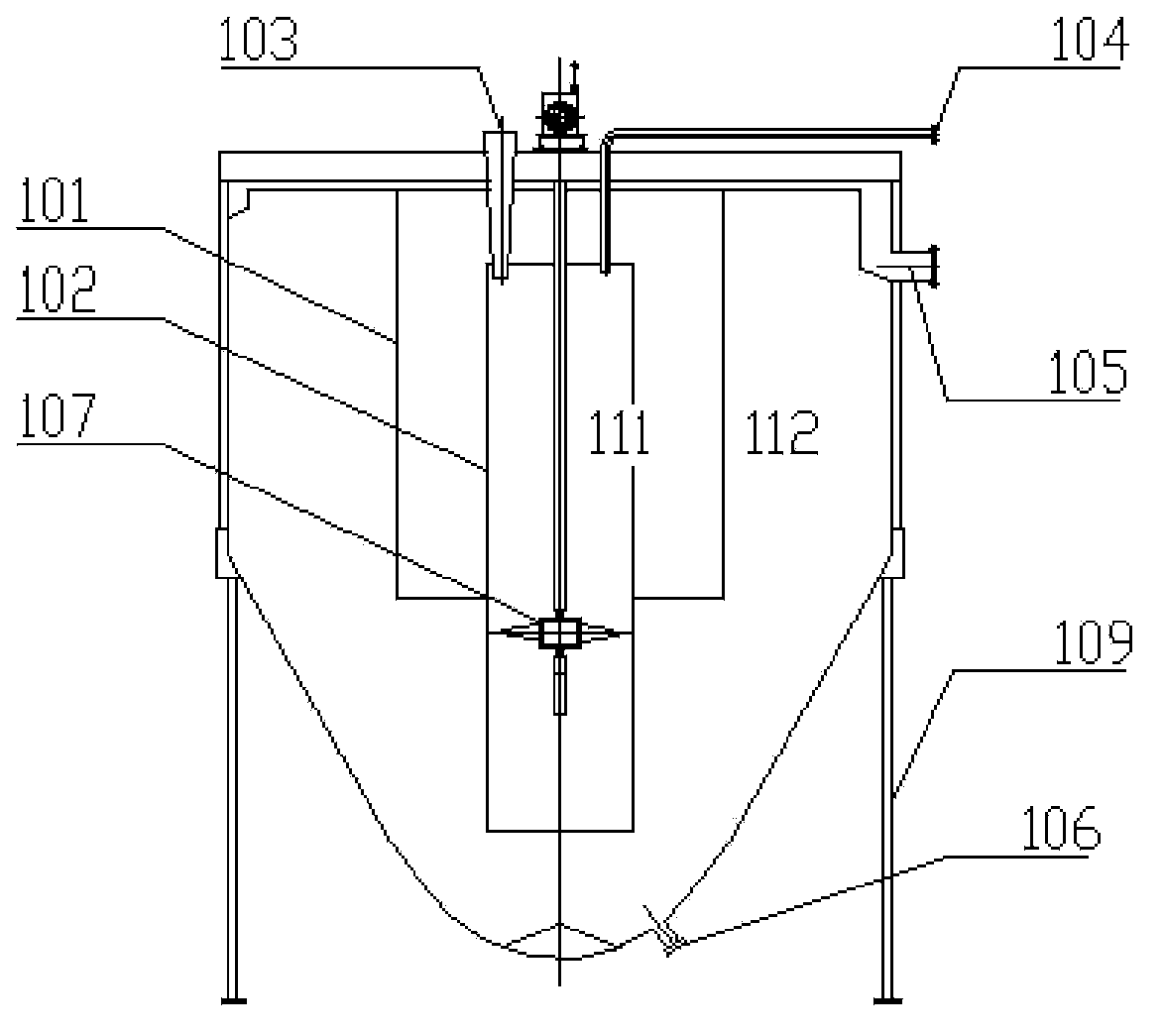

[0045] Embodiment 1: Crystallizer for hydrolysis of carnallite

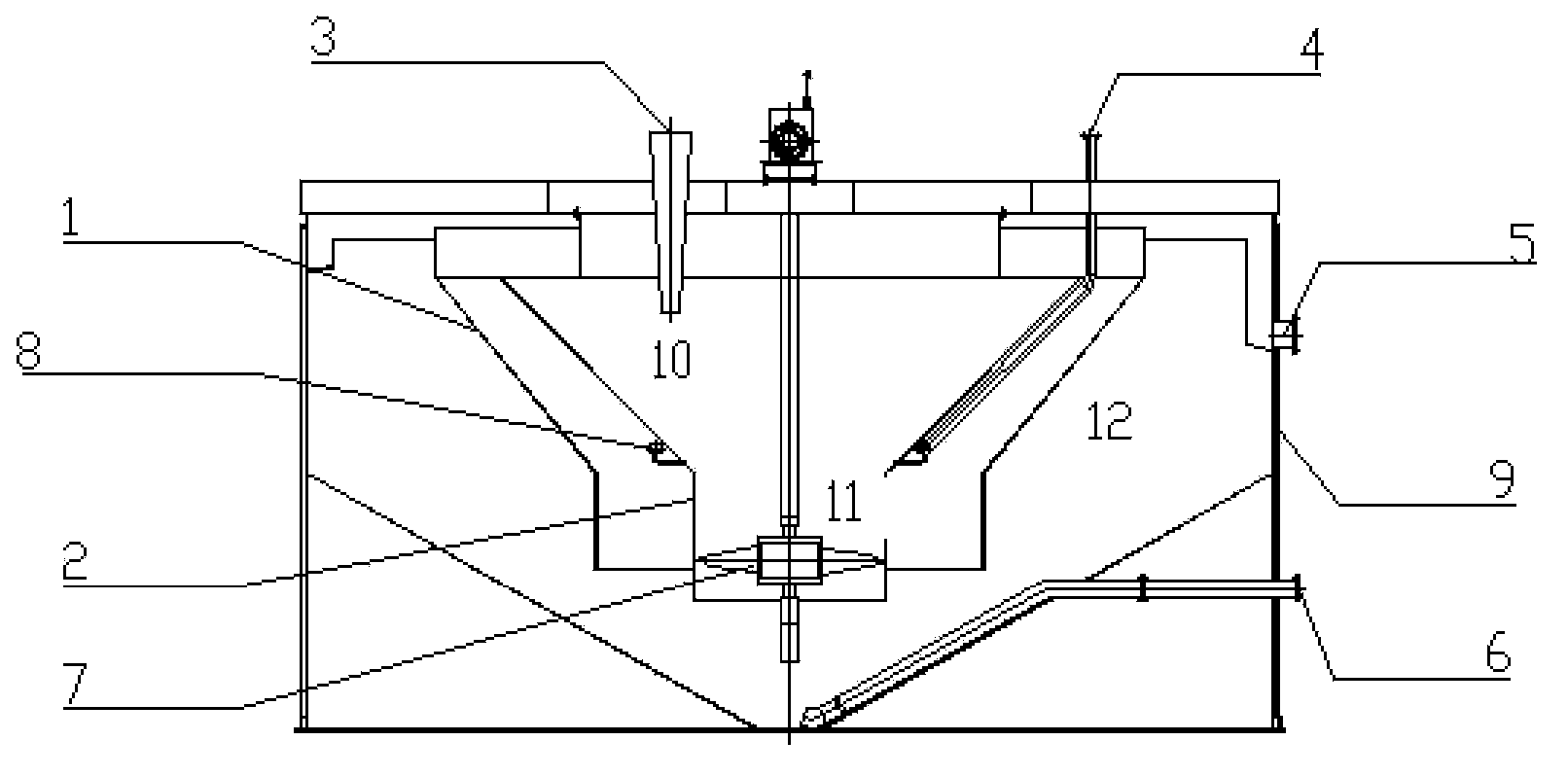

[0046] The structure of the crystallizer is attached as figure 2 As shown, it includes a housing 9, an inner cylinder 2 and an outer cylinder 1 arranged in the housing 9, a carnallite inlet 3 and a mother liquor inlet 4 communicated with the inner cylinder 2, and a decomposition liquid outlet 5 is arranged on the upper part of the housing 9 , the product outlet 6 is set at the bottom of the housing 9, the inner cylinder 2 is located in the outer cylinder 1 and is coaxial with the outer cylinder 1, and a stirring device is provided at the bottom of the inner cylinder 2; it is characterized in that the inner cylinder 2 and The longitudinal cross-sectional shape of the outer cylinder 1 is that the upper part is an inverted cone, while the lower part is rectangular; the distance between the bottom of the inner cylinder 2 and the bottom of the elliptical cone shell is greater than the distance between the bottom of t...

Embodiment 2

[0054] Example 2: Crystallizer for hydrolysis of carnallite

[0055] The implementation of this embodiment is the same as that of Example 1, except that the angle between the inverted tapered side of the outer cylinder 1 and the extended line of the rectangular side is 40°, and the angle between the inverted tapered side of the inner tube 2 and the extended line of the rectangular side The angle is 50°, and the included angle between the shell side wall of the crystallizer and the shell bottom is 70°.

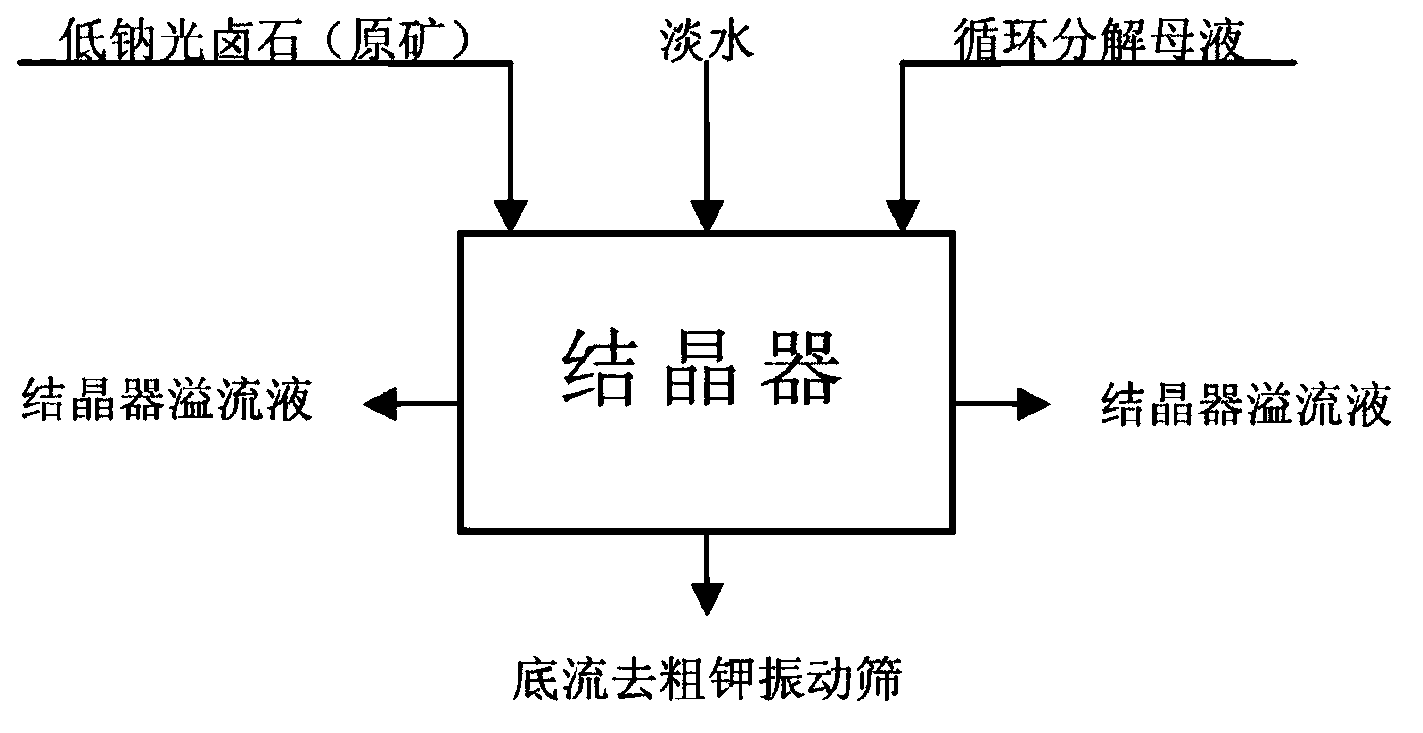

[0056] Use this embodiment crystallizer, according to appendix image 3 The process flow and the steps described in the instructions are carried out under the following conditions for carnallite hydrolysis: the processing capacity of low-sodium carnallite is 450t / h, and the underflow flow rate is controlled at 340m 3 / h, the underflow concentration is 28% (volume ratio). Adopt my country's existing analysis standard or literature data to analyze relevant components in low-sod...

Embodiment 3

[0057] Example 3: Crystallizer for hydrolysis of carnallite

[0058] The implementation of this embodiment is the same as that of Example 1, except that the included angle between the inverted tapered side of the outer cylinder 1 and the extended line of the rectangular side is 38°, and the included angle between the inverted tapered side of the inner tube 2 and the extended line of the rectangular side The angle is 40°, and the included angle between the shell side wall of the crystallizer and the shell bottom is 57°.

[0059] Use this embodiment crystallizer, according to appendix image 3 The process flow and the steps described in the instruction manual carry out the hydrolysis of carnallite under the following conditions: the processing capacity of low-sodium carnallite is 380t / h, and the flow rate of the underflow is controlled at 360m 3 / h, the underflow concentration is 32% (volume ratio). Adopt my country's existing analysis standard or literature data to analyze re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com