Wireless Control Access System for Plate Roller in Large Printing Plate Library

A wireless control and access system technology, applied in storage devices, transportation and packaging, etc., can solve problems such as low integration of simple plate roll storage racks, increased printing factory costs, and scratches on the plate roll surface, achieving The management program is simple and easy to operate, fast and automatic plate taking, and the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

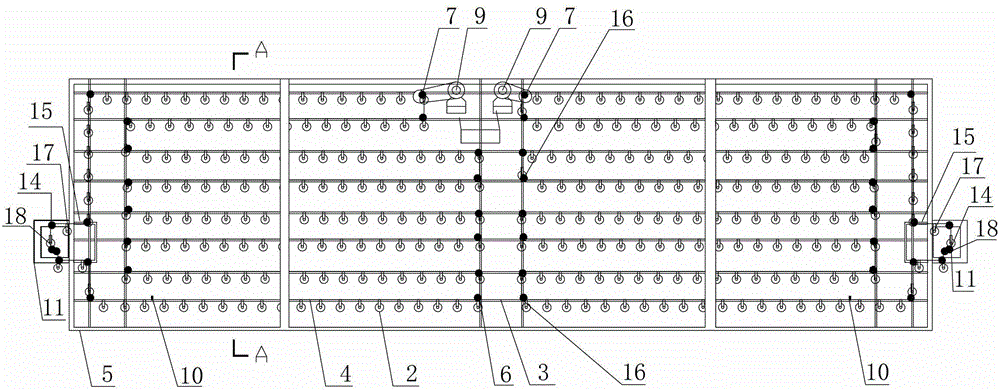

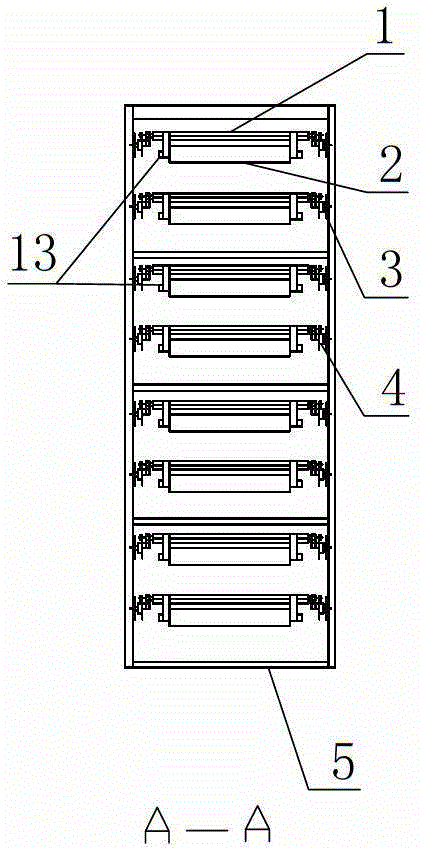

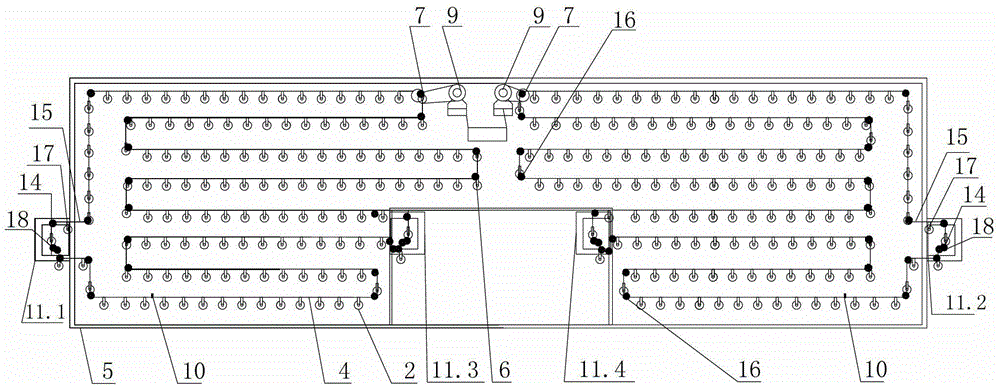

[0021] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , 2 As shown in , the wireless control and access system for large-scale printing plate library plate rollers includes a console 15, a plate roll storage frame 5, a motor 9 with a deceleration device, a motor drive module 18 connected to the motor 9, a handheld wireless control terminal 12 and Two groups of guide rails 3 are symmetrically arranged on both sides of the plate roll storage frame 5; position positioning sensors 16 are arranged in multiple places on the guide rails 3; a transmission chain 4 is laid on each group of guide rails 3 and steering gear 6, and two groups of transmission chains 4 is a multi-row synchronous vertical rotation arrangement respectively forming a closed connection end to end, a steering gear 6 is provided at the vertical rotation angle of the transmission chain 4, and a pair of transmission chains 4 located on both sides of the plate r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com