System and method for large-scale forme storehouse forme roller storage and taking

An access system and plate roller technology, which is applied in storage devices, transportation and packaging, etc., can solve the problems of scratches on the surface of the plate roller, increase the cost of the printing factory, and the integration of the simple plate roll storage rack is not high, and achieve failure The effect of low efficiency, fast and automatic plate taking, and simple and easy management procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

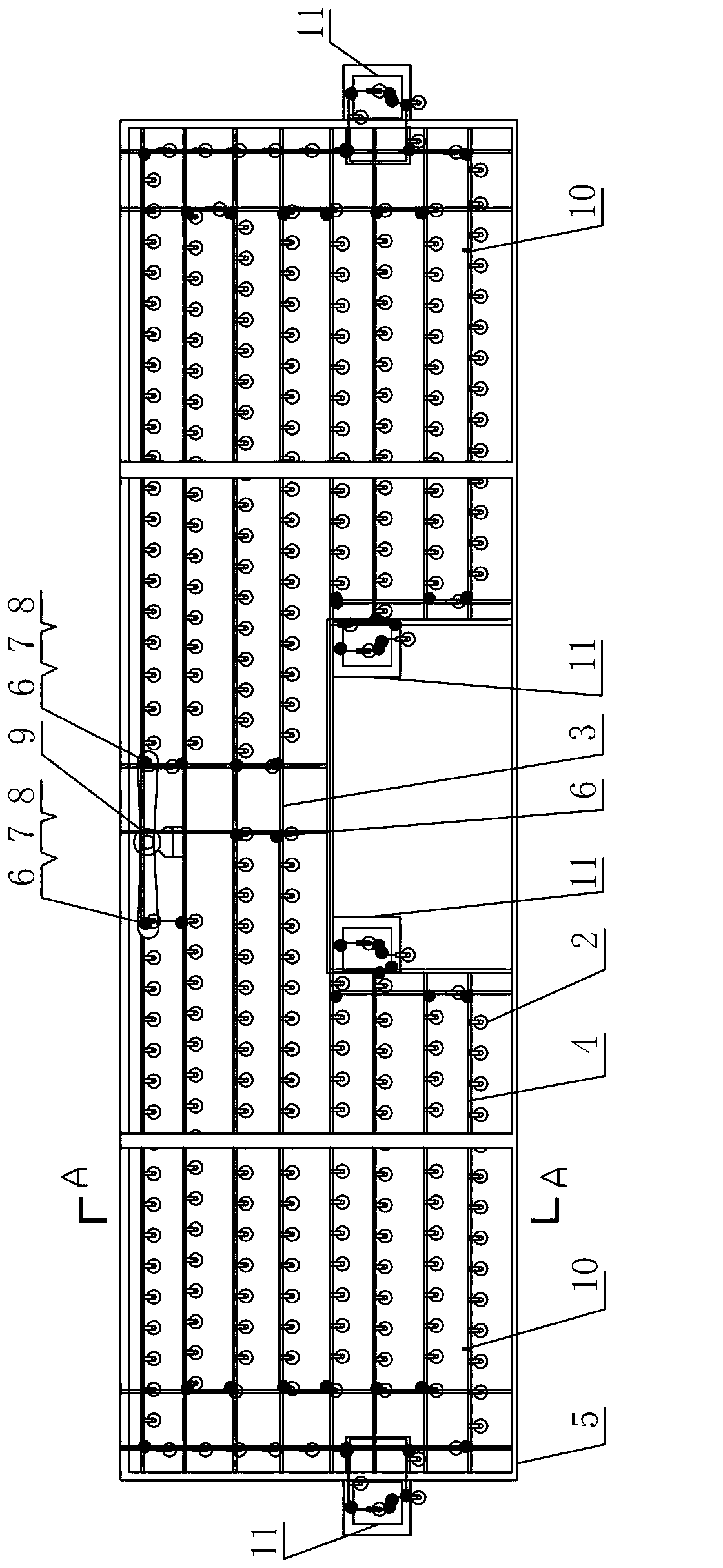

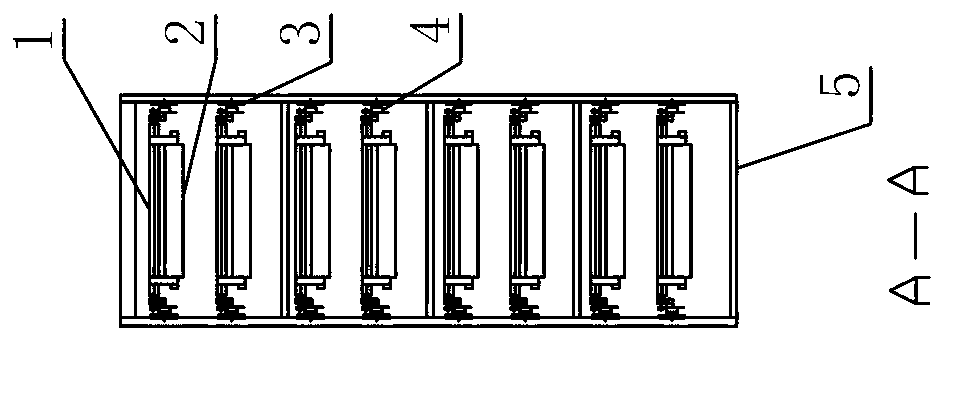

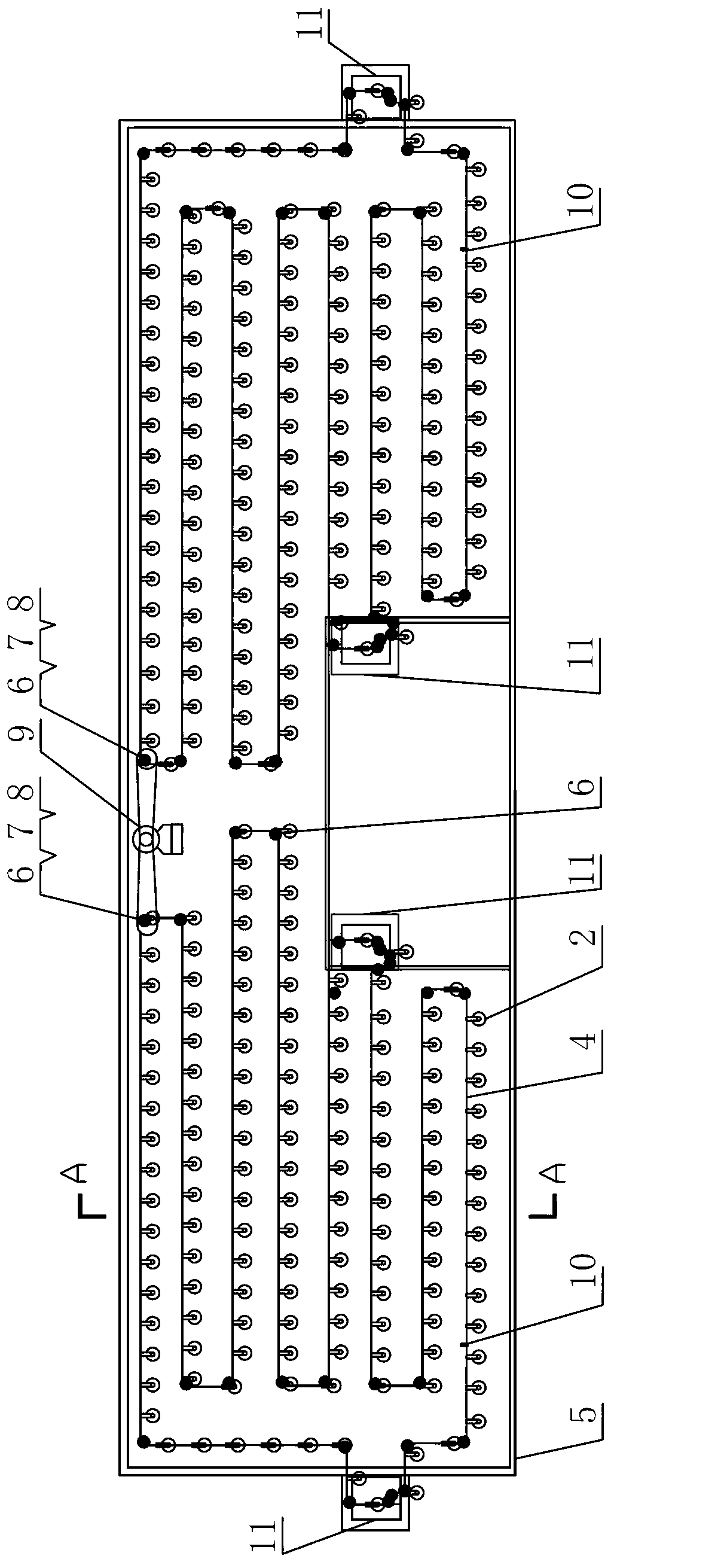

[0027] The present invention will be further explained below in conjunction with the drawings: figure 1 , 2 As shown in the above-mentioned large-scale printing plate library plate roller access system and method, the printing plate library includes a plate roller storage frame 5, guide rails 3 symmetrically fixed on both sides of the plate roller storage frame, and storage on the plate roller In the frame, a conveyor chain 4 connected end to end and arranged vertically rotating, and a plate roller frame 1 fixedly installed at both ends of the conveyor chain. The conveyor chain is arranged along a guide rail so that the guide rail serves as a support for the conveyor chain. Both sides of the plate roller frame 1 There is a binding belt for hanging the binding plate roller, the plate roller storage frame is provided with one or more plate access openings 11, and the plate roller storage frame is fixedly equipped with a motor 9 with a deceleration device, which is driven and transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com