An access method for a large-scale printing plate storehouse plate roller access system

An access method and access system technology, which is applied in the access field of the plate roll access system of a large printing plate library, can solve the scratches on the plate roll surface, increase the cost of the printing factory, and integrate the simple plate roll storage rack No high-level problems, low failure rate, fast and automatic plate taking, and simple and easy management procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

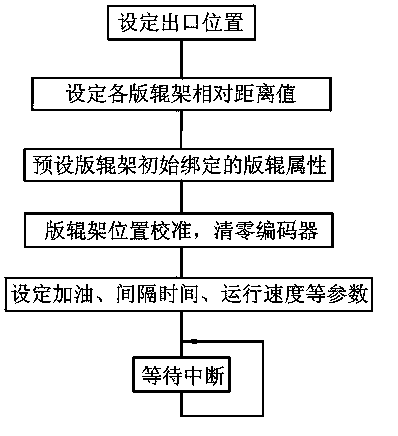

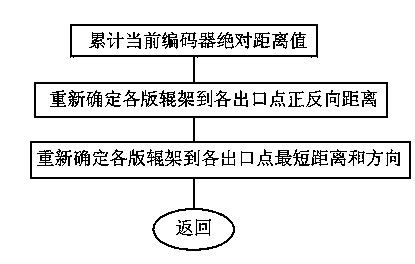

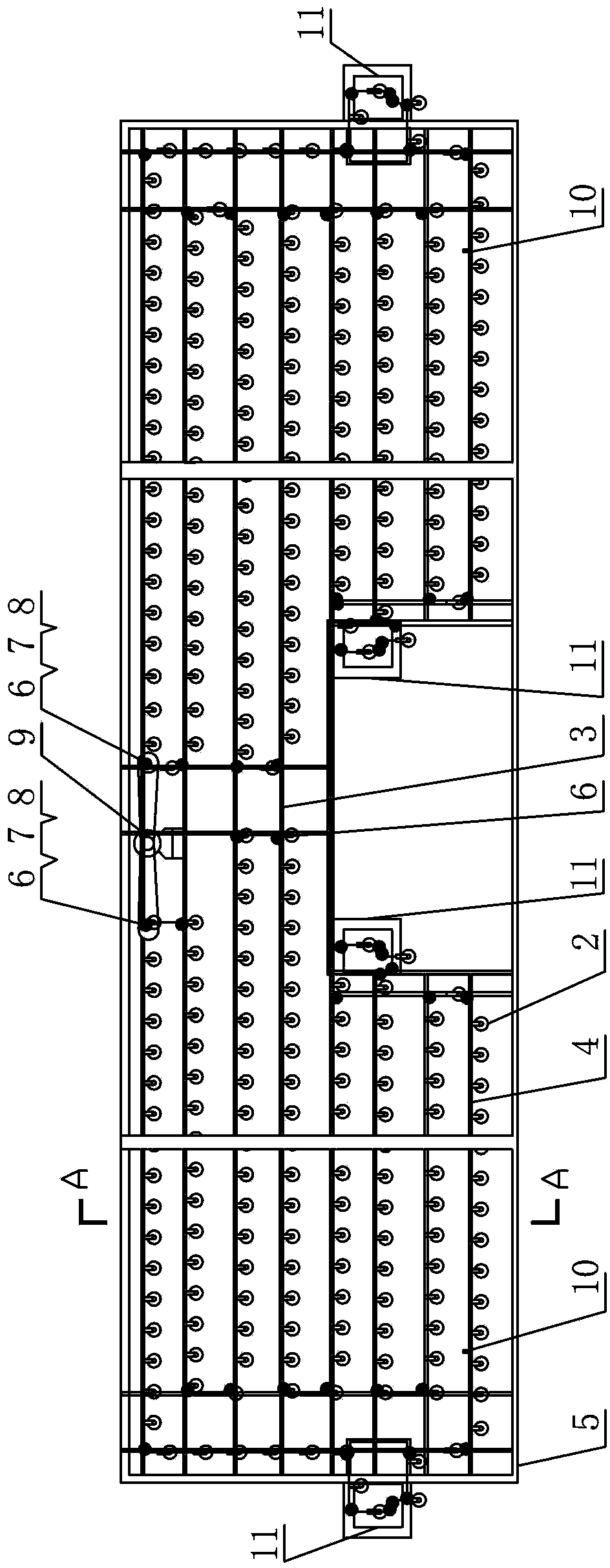

[0027] Below in conjunction with accompanying drawing, the present invention is further described: as figure 1 , 2 As shown in , the access method for a large-scale printing plate library plate roll access system, the printing plate storehouse includes a plate roll storage frame 5, guide rails 3 symmetrically fixed on both sides inside the plate roll storage frame, The transmission chain 4 connected end to end and vertically rotated in the storage frame of the plate roll, the plate roll frame 1 fixedly installed at both ends of the plate roll, the plate roll frame is arranged along the guide rail so that the guide rail is used as the support of the plate roll, and the plate roll Both sides of the frame 1 are provided with binding belts for hanging and binding the plate rolls. The plate roll storage frame is provided with one or more access plates 11, and the plate roll storage frame is fixed with a motor 9 with a deceleration device. The motor drives the conveyor chain to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com