Heavy metal trapping material prepared by using waste polyurethane sponge, and preparation method

A polyurethane sponge and capture material technology, applied in the field of heavy metal capture materials and its preparation, can solve the problems of difficult removal of heavy metal ions, a large number of flocs and sludge, and the inability to regenerate and reuse, so as to achieve waste utilization and low density , the effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

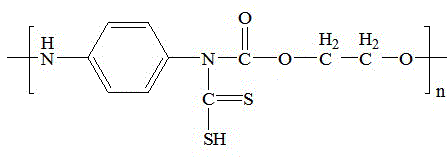

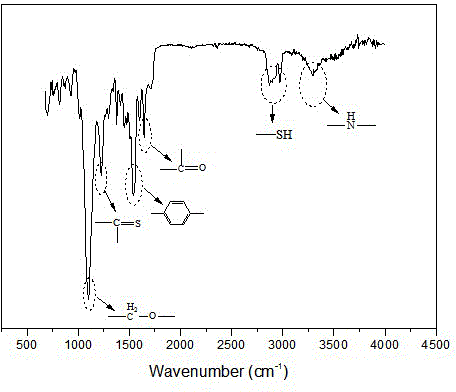

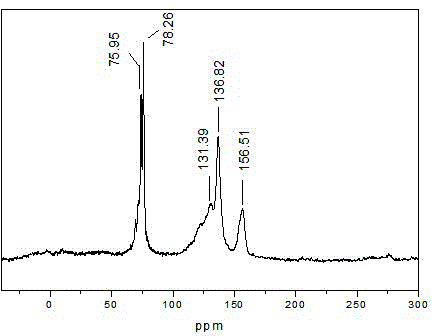

[0041] Extract 2.0 g of polyurethane sponge with ethanol in a Soxhlet extractor for 4 hours, put it in a large beaker after drying, add 400 ml of 2 mol / L sodium hydroxide solution, stir for 4 hours, and wash 3 times with distilled water (500ml each time). Transfer the sponge into a stainless steel reaction kettle, add 200 ml of ethanol and 20 ml of carbon disulfide. The reaction temperature is 5 degrees Celsius, the reaction pressure is 0.1 MPa, and the reaction is stirred at a speed of 60 r / min for 4 hours. The product obtained in the reaction is subjected to solid-liquid separation, washed with ethanol, and dried to obtain a spongy heavy metal capture material (PU-DTCA ). The PU-DTCA chemical structure that embodiment 1 makes is as figure 1 said n is the degree of polymerization, in the range of 500-1200 (the degree of polymerization of the polyurethane sponge used is usually 500-1200), such as figure 2 The FT-IR spectrum of PU-DTCA is shown, the abscissa is the wave n...

Embodiment 2

[0048] Extract 2.0 g of polyurethane sponge with acetone in a Soxhlet extractor for 4 hours, put it in a large beaker after drying, add 400 ml of 3mol / L sodium hydroxide solution, stir for 4 hours, and wash with distilled water for 3 times (500ml each time). Transfer the sponge into a stainless steel reaction kettle, add 200 ml of ethanol and 30 ml of carbon disulfide. The reaction temperature is 8 degrees Celsius, the reaction pressure is 0.1 MPa, and the reaction is stirred and reacted at a speed of 60 r / min for 4 hours. The reaction product is subjected to solid-liquid separation, washed with ethanol, and dried to obtain a spongy heavy metal trapping material PU-DTCA.

[0049] Static equilibrium adsorption test: at a temperature of 20 degrees Celsius, add 0.1g of sponge adsorption material to 5 Erlenmeyer flasks, and add 100ml of heavy metal ions with an initial concentration of 40, 80, 120, 160, 200mg / L in each Erlenmeyer flask Solution, after shaking in a constant temper...

Embodiment 3

[0055] Add 2.0 g of polyurethane sponge to 200 ml of ethanol and extract in a Soxhlet extractor for 4 hours, place it in a 3-neck bottle after drying, then add 400 ml of 4mol / L sodium hydroxide solution, stir for 4 hours, and use Wash with distilled water 3 times (500 ml each time). Transfer the sponge into a stainless steel reaction kettle, add 200 ml of ethanol and 40 ml of carbon disulfide. The reaction temperature is 10 degrees Celsius, the reaction pressure is 0.1 MPa, and the reaction is stirred at a speed of 60 r / min for 4 hours. The reaction product is subjected to solid-liquid separation, washed with ethanol, and dried to obtain a spongy heavy metal trapping material PU-DTCA.

[0056] Static equilibrium adsorption test: at a temperature of 20 degrees Celsius, add 0.1g of sponge adsorption material to 5 Erlenmeyer flasks, and add 100ml of heavy metal ions with an initial concentration of 40, 80, 120, 160, 200mg / L in each Erlenmeyer flask Solution, after shaking in a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com