Heating seat cushion

A seat cushion and heating core technology, applied in the field of seat cushions, can solve problems such as copper sheets are easily broken, heat cannot be transmitted, heating cushions lose heating and heating effects, etc., and achieve the effect of controlling the heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

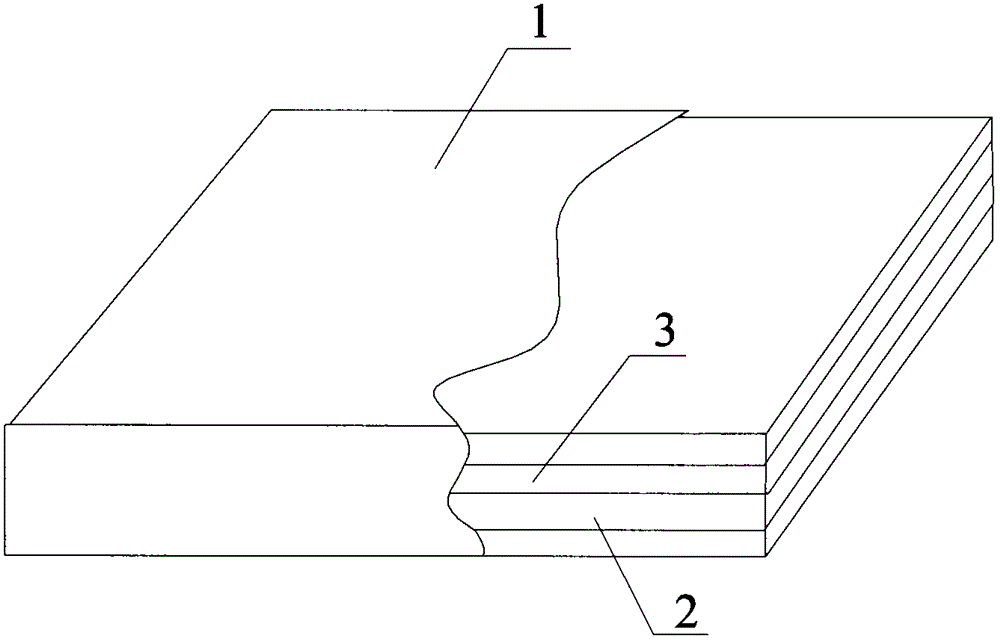

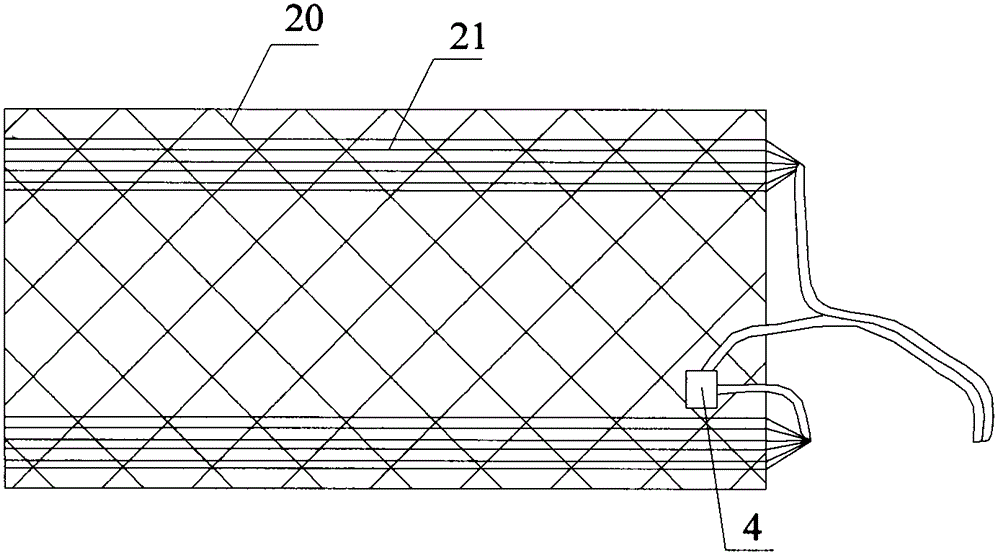

[0021] see figure 1 and figure 2 , Embodiment 1 of the present invention: a heating cushion, including a cushion body 1, a heating core 2, and a temperature control device. The temperature control device is connected to the heating core 2. Including electric heating wire and carbon fiber heating layer, the carbon fiber heating layer is a grid-like heating element formed by interlacing carbon fiber heating wire 20; in this embodiment, the electric heating wire is two groups, and the two groups of electric heating wire are respectively placed in the carbon fiber heating The two ends of the layer are thermally connected to the carbon fiber heating wire 20 on the carbon fiber heating layer, and the two sets of heating wires are connected to the temperature control device; the heating cushion also includes a flame-retardant layer 3, and the flame-retardant layer 3 is placed on the cushion body 1 Inside, the flame retardant layer 3 covers the carbon fiber heating layer and two set...

Embodiment 2

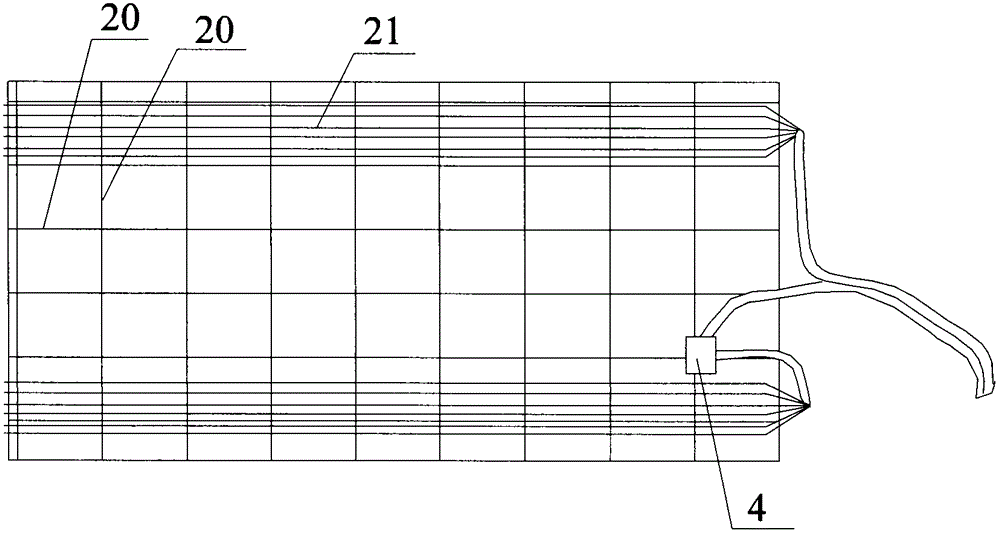

[0027] Embodiment two, please refer to image 3 The difference between this embodiment and Embodiment 1 is that the carbon fiber heating layer is a rectangular grid-shaped heating element formed by interlacing carbon fiber heating wires 20 , and the metal wires 21 in this embodiment are copper wires.

Embodiment 3

[0028] Embodiment 3. The difference between this embodiment and Embodiment 1 is that the carbon fiber heating layer is an elliptical grid-shaped heating element formed by interlacing carbon fiber heating wires 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com