A carbon fiber heating plate and its production process

A technology of carbon fiber heating and carbon fiber heating wire, applied in the field of carbon fiber heating plate and its production process, can solve problems such as poor contact, loss of electrical connection, displacement or looseness, achieve heat balance, not easy to loosen, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

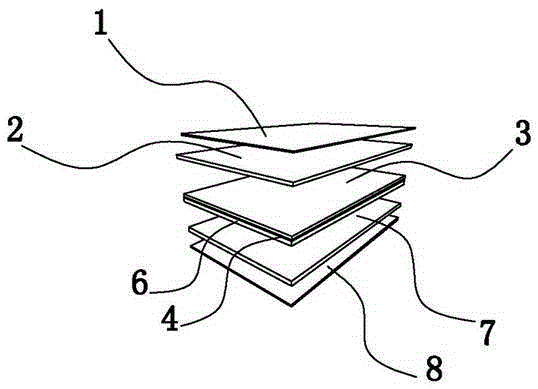

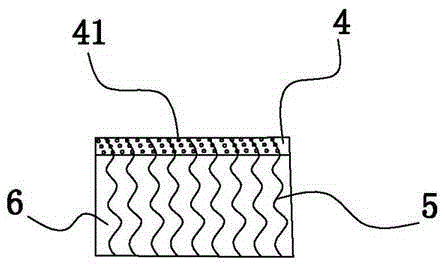

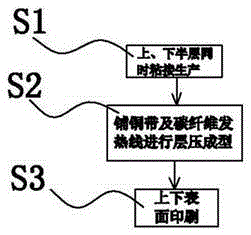

[0026] like figure 1 and 2 As shown, the carbon fiber heating plate includes an upper insulating layer 2, a lower insulating layer 7, an upper fiber mesh 3, a lower fiber mesh 6 and a copper strip 4, and both the upper insulating layer 2 and the lower insulating layer 7 are made of PET. A plurality of connection holes 41 are opened on the copper strip 4, and the connection holes 41 are composed of multiple groups of uniformly arranged connection holes 41, and each group of connection holes 41 is composed of three connection holes 41 and is inclined relative to the edge of the copper strip 4. , the carbon fiber heating wire 5 is evenly arranged along the vertical direction of the copper strip 4, and each carbon fiber heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com