Device and method for generating double-layer plasma photon crystal

A plasma and photonic crystal technology, which is applied in the field of plasma application technology and optics, can solve the problems of limited application fields and application prospects, single modulation method, and limited wavelength range of light modulation, so as to achieve diversification and broaden the wavelength band. , the effect of a wide range of application fields and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

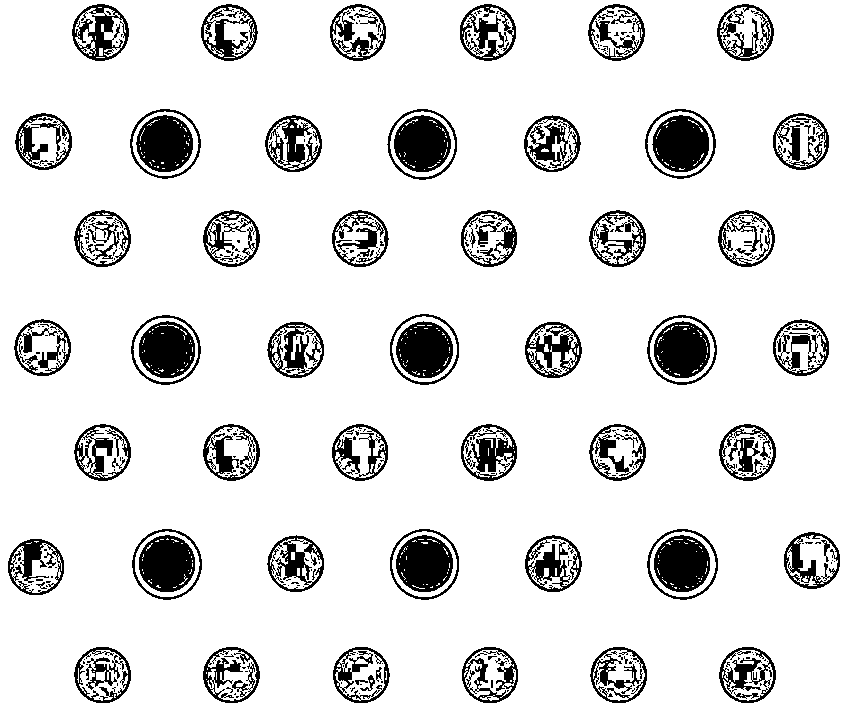

[0029] Such as figure 1 As shown, the device for producing double-layer plasma photonic crystals of the present invention is to symmetrically arrange two airtight dielectric containers in a horizontal cylindrical vacuum reaction chamber 1, and fill the airtight dielectric containers with water to form two polar plates Opposite water electrode 2. The two water electrodes 2 are electrically connected to a plasma generating power source 3 . Water electrode 2 also can adopt plexiglass tube, both sides are sealed with glass baffle 7, is filled with water and is built-in copper ring 6, and the power line of plasma generation power supply 3 is connected on the copper ring 6. The thickness of the glass block 7 is between 0.1 and 5mm, which is used as a discharge medium. An air inlet and an air outlet are opened on the wall body of the vacuum reaction chamber 1 .

[0030] Two frames 4 with different thicknesses are arranged between the two water electrodes 2 as the boundaries of the...

Embodiment 2

[0036]The method for producing double-layer plasma photonic crystals in the present invention is as follows: a vacuum reaction chamber 1 is provided, an air inlet and an air outlet are opened on its wall body, and two water electrodes opposite to each other are arranged in the vacuum reaction chamber 1 2. The water electrode 2 is a plexiglass tube sealed with glass baffles 7 on both sides and filled with water, and a built-in copper ring 6 is electrically connected to the plasma generating power supply 3 . Wherein, water is used as an electrode, and a glass block 7 with a thickness between 0.1 and 5 mm is used as a discharge medium. Two frames 4 with different thicknesses are arranged between the two water electrodes 2 as the boundaries of the discharge air gap, and the thickness of the frames 4 is between 0.1 mm and 20 mm. A dielectric plate 5 is arranged between the frames 4 to separate the discharge gap into two layers with adjustable thickness. In order to improve the bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com