Constant width film stretching device combined with X-ray scattering, and experimental method thereof

A technique of stretching device and experimental method, which is applied in material analysis using radiation diffraction, etc., can solve the problem of less research on extensional flow, and achieve continuous adjustment of stretching rate and stretching ratio, precise control, easy disassembly, and easy disassembly. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment further illustrate the present invention.

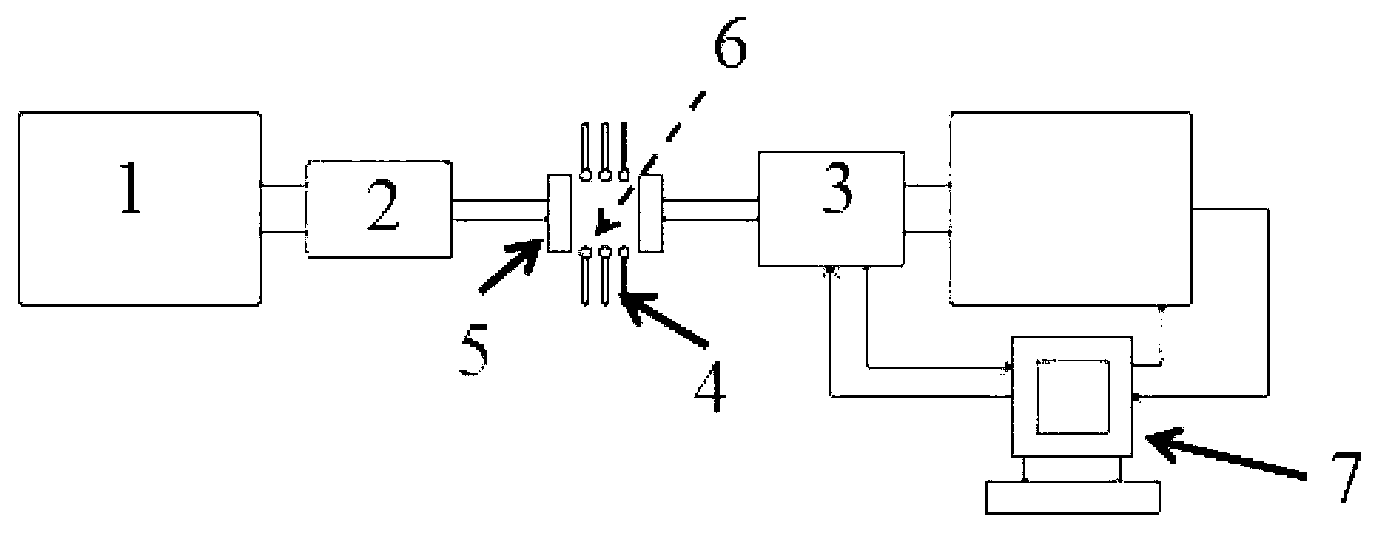

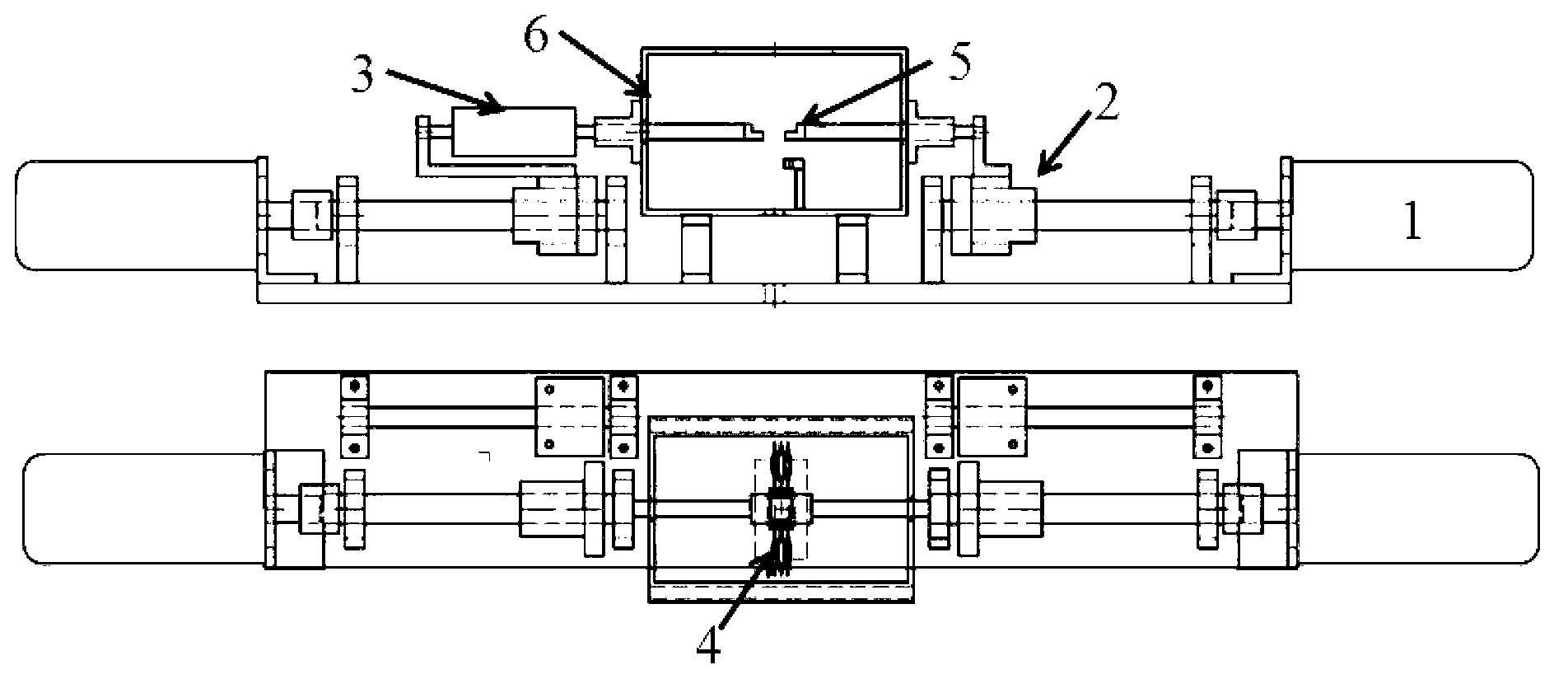

[0042] A constant width film stretching device combined with X-ray scattering, see attached figure 1, The high-precision servo motor 1 drives the ball screw 2 to move, and converts the motor rotation into linear motion. The ball screw drives the movement of the longitudinal chuck 5 to realize the stretching of the film sample 6 . The running speed is continuously adjustable, which can well match the response of different materials to the stretching speed. 4 is the horizontal chuck, using a scissors mechanism, which not only ensures that the width of the sample remains constant during stretching, but also satisfies the uniform movement of the chuck point with the sample without interfering with the longitudinal stretching of the sample. During the stretching process, the tension sensor 3 tracks the tension change. This device uses the Labview software control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com