Rapid leak detection device and leak detection method for total leakage rate of spacecraft condensate piping system

A technology for condensate water pipes and spacecraft, which is applied in the direction of measuring the acceleration and deceleration rate of fluids and using liquid/vacuum degree for liquid tightness measurement, etc. problems, to achieve the effect of saving leak detection time, improving leak detection efficiency and fast leak detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

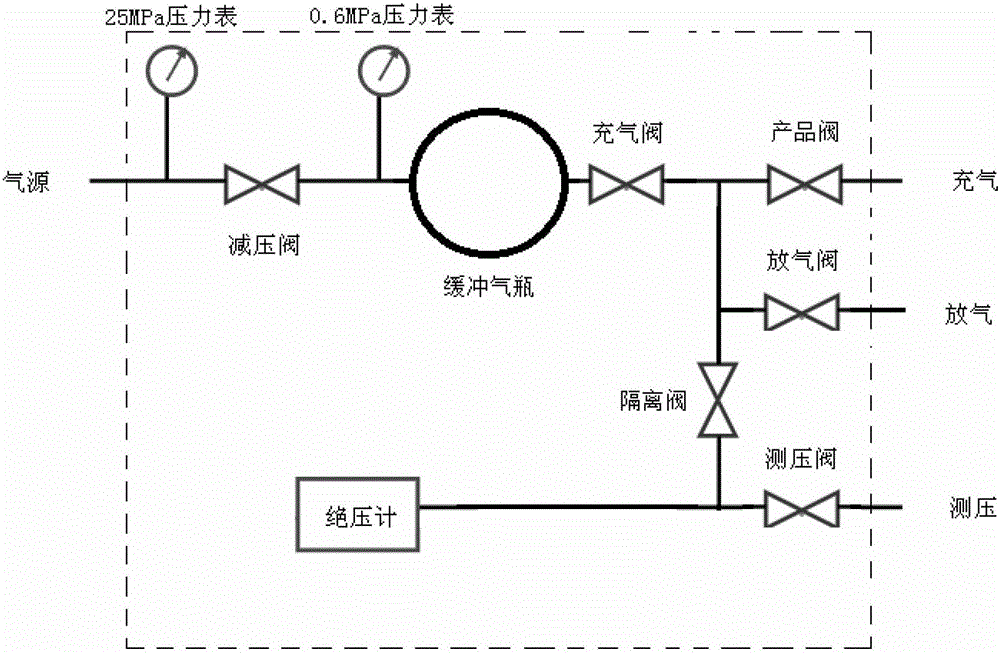

[0030] figure 1 It is a structural schematic diagram of the rapid leak detection device used for testing the total leak rate of the spacecraft condensate piping system according to the present invention. The device includes a high-precision absolute pressure gauge (such as an absolute pressure gauge with a range of 0kPa to 250kPa and an accuracy of 0.01% FS, that is, ±25Pa), a pressure reducing valve, a high pressure gauge, a low pressure gauge, five stop valves, and a buffer gas cylinder. It is connected with the corresponding pipeline, wherein, the gas source is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com