A leak detection device and leak detection method for large leak measurement

A technology of leak detection and gas storage chamber, which is applied in the direction of measuring the rate of increase and deceleration of fluid, and liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of huge deviation of test results, exhaustion, helium overflow, etc. , to achieve the effects of simple structure, fast leak detection speed and accurate leak detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

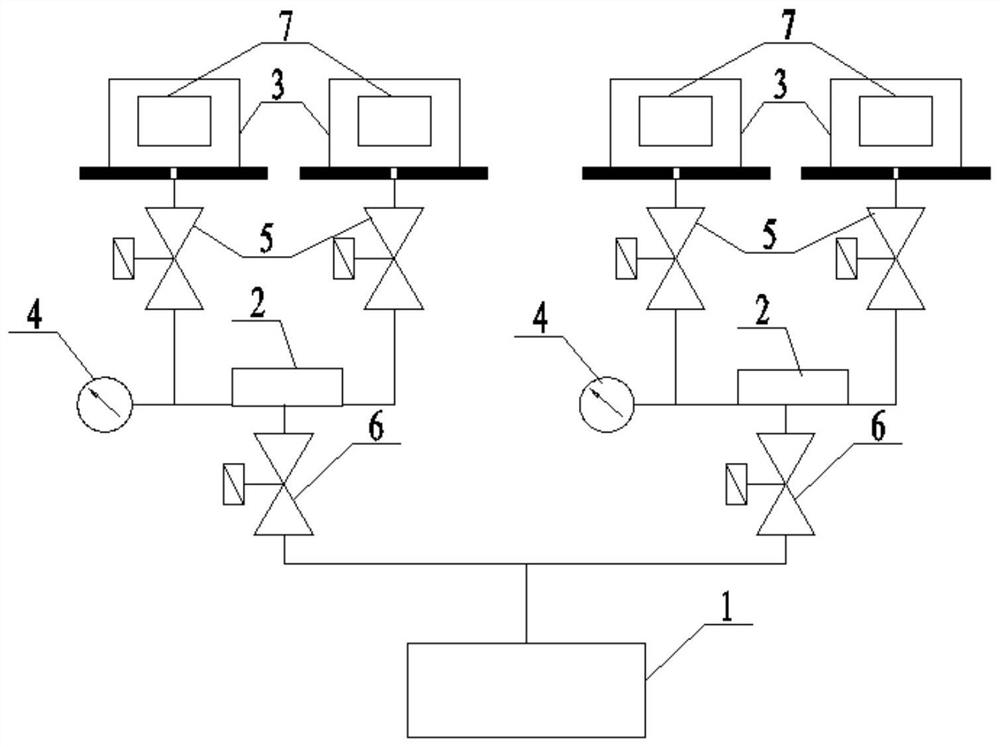

[0022] Such as figure 1 As shown, this embodiment provides a leak detection device for large leak measurement, including a gas source 1, a gas storage chamber 2 connected to the gas source 1 through a gas source pipeline, and a vacuum chamber connected to the gas storage chamber 2 through an inflation pipeline. Chamber 3, a pressure sensor 4 connected to the gas storage chamber 2, an inflation valve 5 is provided at the interface connected between the vacuum chamber 3 and the inflation pipeline, and an air source valve 6 is provided at the interface connected between the gas storage chamber 2 and the gas source pipeline;

[0023] Among them, several vacuum chambers 3 are respectively connected to the gas storage chamber 2 through a plurality of inflatable pipes, and several gas storage chambers 2 are respectively connected to the gas source 1 through gas source pipes.

[0024] The leak detection method provided by the leak detection device in this embodiment is characterized i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com