Part height measuring method based on laser ranging

A technology of laser distance measurement and measurement method, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as misjudgment, missed detection, time-consuming, time-wasting, etc., and achieve the effect of improving measurement efficiency and saving measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

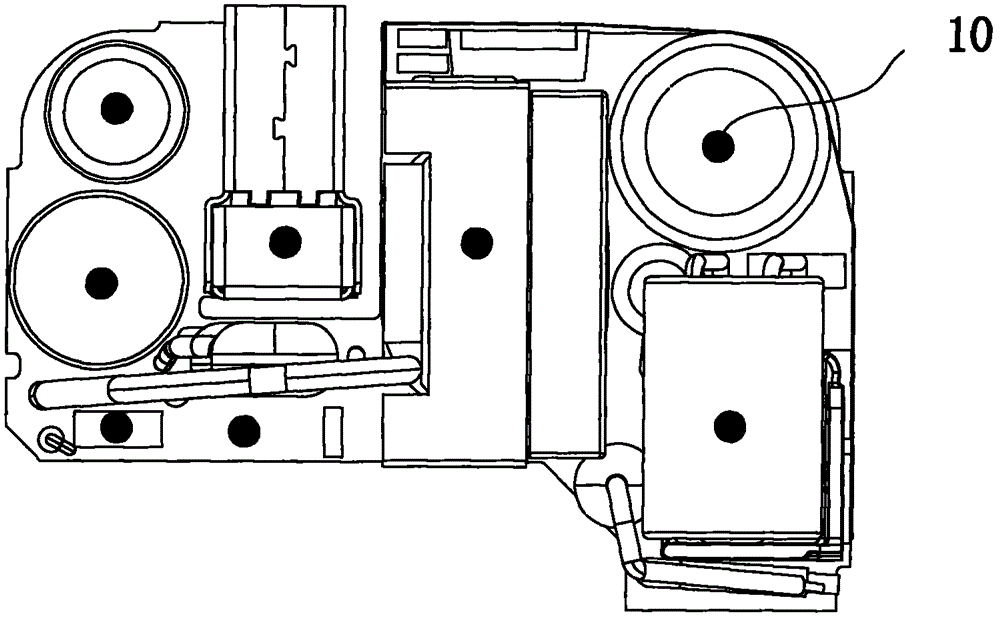

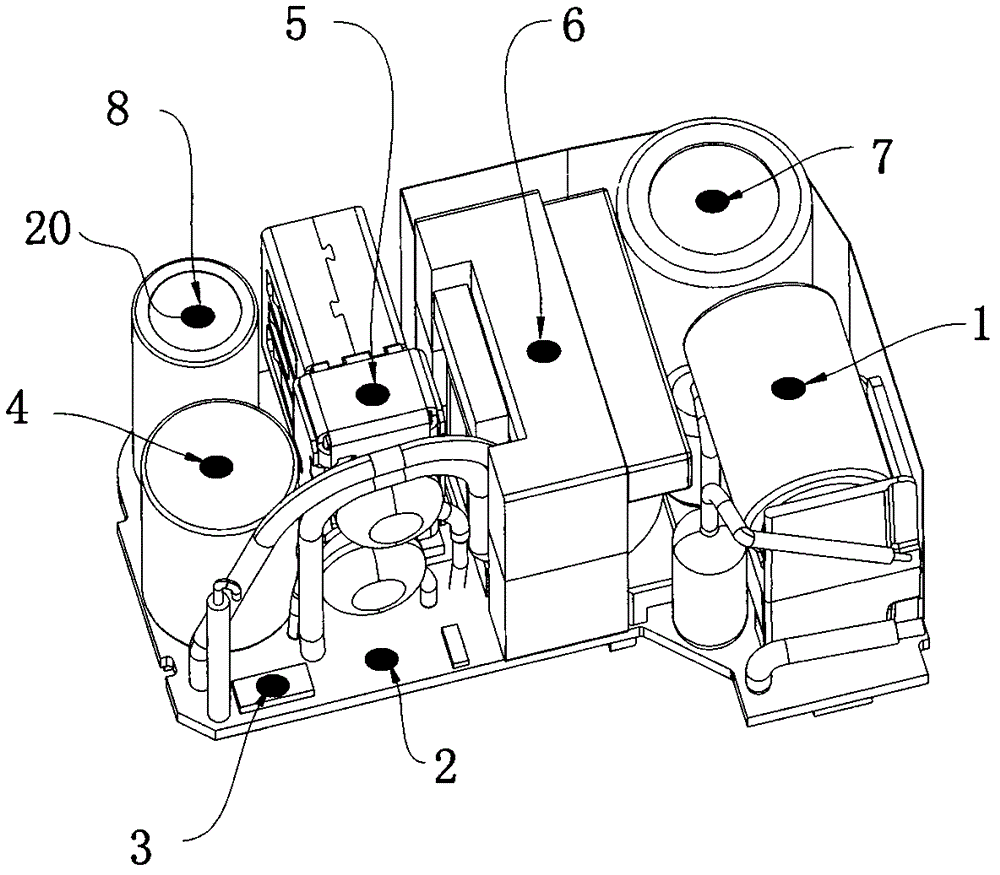

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following examples are given and described in detail with reference to the drawings.

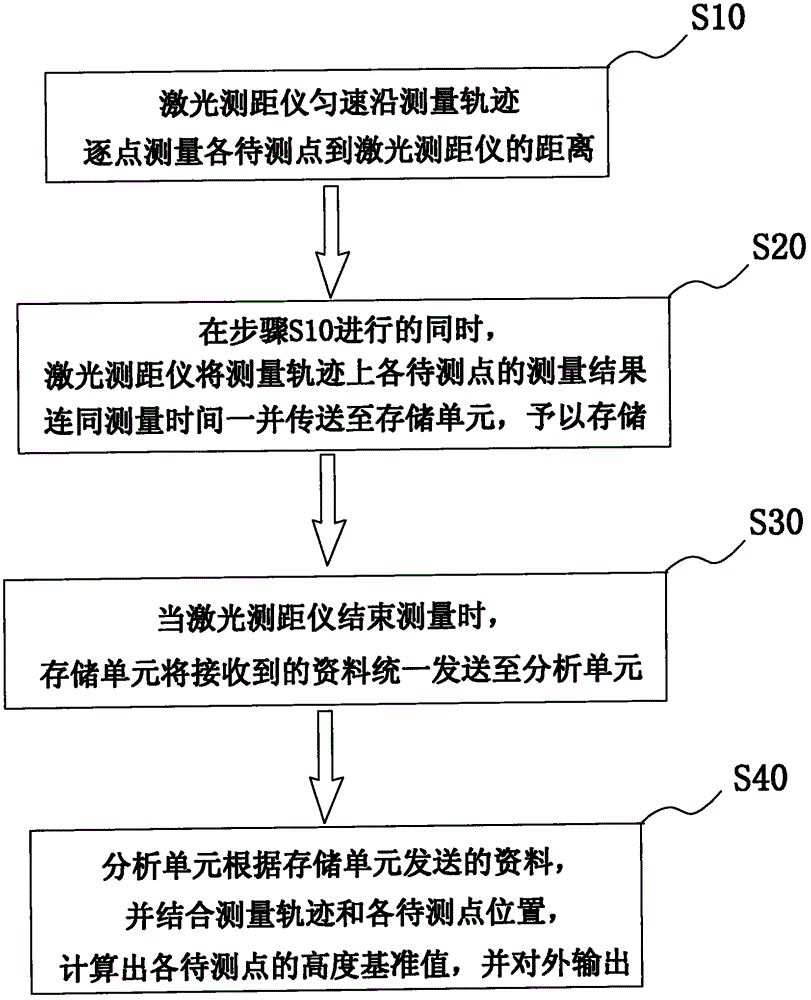

[0021] Such as figure 2 As shown, the method for measuring the height of parts provided by the present invention is based on laser ranging technology, and includes the following steps:

[0022] Step S10: the laser range finder measures the distance from each point 20 to be measured to the laser range finder point by point along the measurement track 30 at a uniform speed;

[0023] Step S20: While performing step S10, the laser rangefinder transmits the measurement results of each point 20 to be measured on the measurement track 30 together with the measurement time to the storage unit for storage. The measurement time is the displacement of the laser rangefinder to the time to be measured at point 20;

[0024] Step S30: When the laser range finder fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com