Energy-saving blowdown device for industrial boilers

A sewage device, industrial boiler technology, applied in the direction of boiler cleaning device, etc., can solve the problems of water and energy waste, water loss, heat energy loss, etc., to avoid the waste of water and heat energy, solve the waste of drainage, reduce the sewage discharge rate and The effect of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

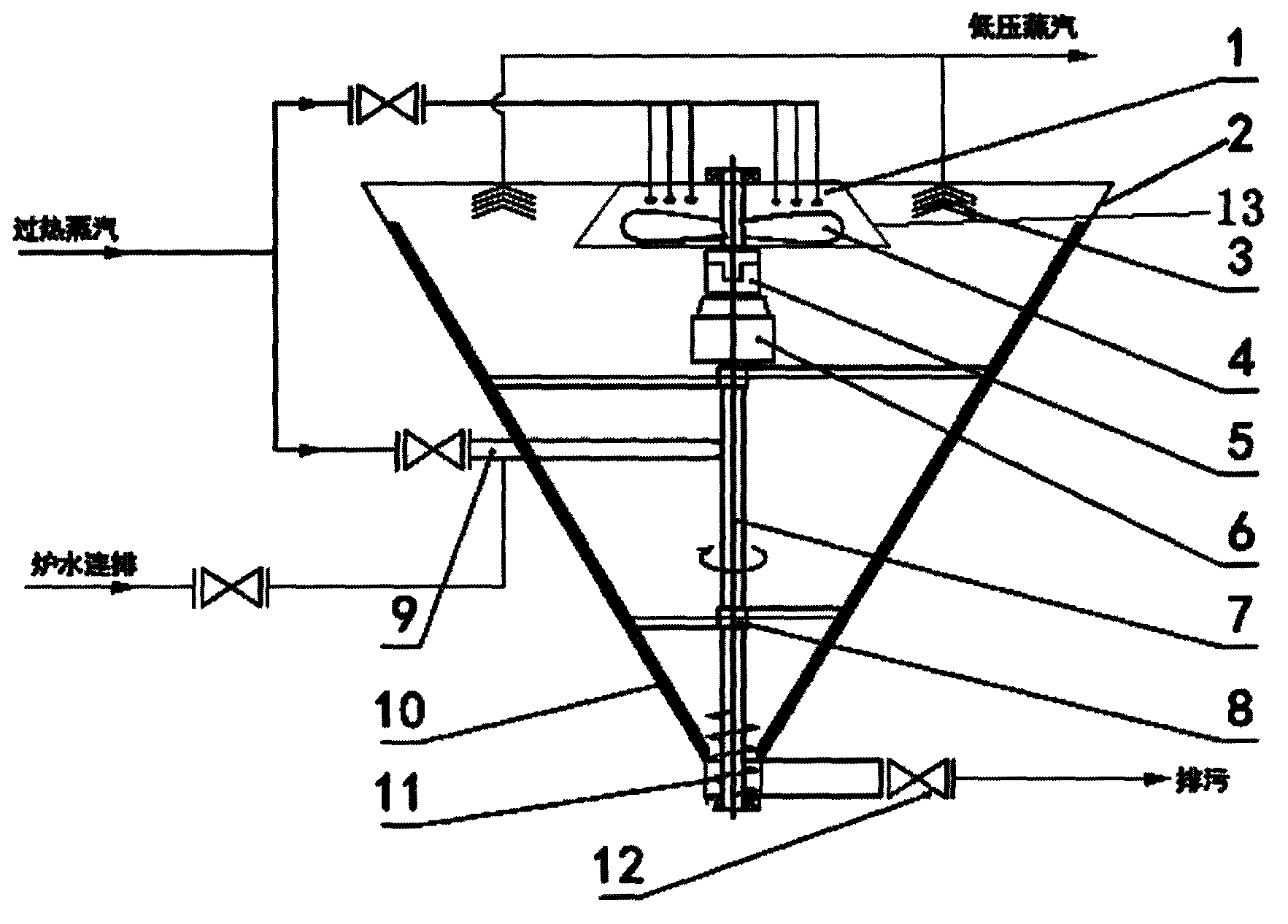

[0009] Example 1 as figure 1 Said, an industrial boiler energy-saving blowdown device, comprising a housing 2, a turbine device, a steam-water mixer 9, and a screw conveyor 11; the steam-water mixer 9 is installed outside the housing 2 and connected to the side of the housing; the screw conveyor 11 is installed under the casing 2; the turbine device is arranged in the casing, including the steam turbine blade 4 and the reducer 6, and the steam nozzle 1 is installed above the steam turbine blade 4; the rotating shaft of the steam turbine blade 4 passes through the magnetic coupling 5 is connected to the reducer 6, the lower part of the reducer 6 is connected to the scraper drive shaft 7; the scraper support 8 is installed on the scraper drive shaft 7, the outer end of the scraper support 8 is connected to the scraper 10, and the scraper 10 is close to the shell 2 The inner wall; the rotating shaft of the screw conveyor 11 is connected to the scraper drive shaft 7 through a tran...

Embodiment 2

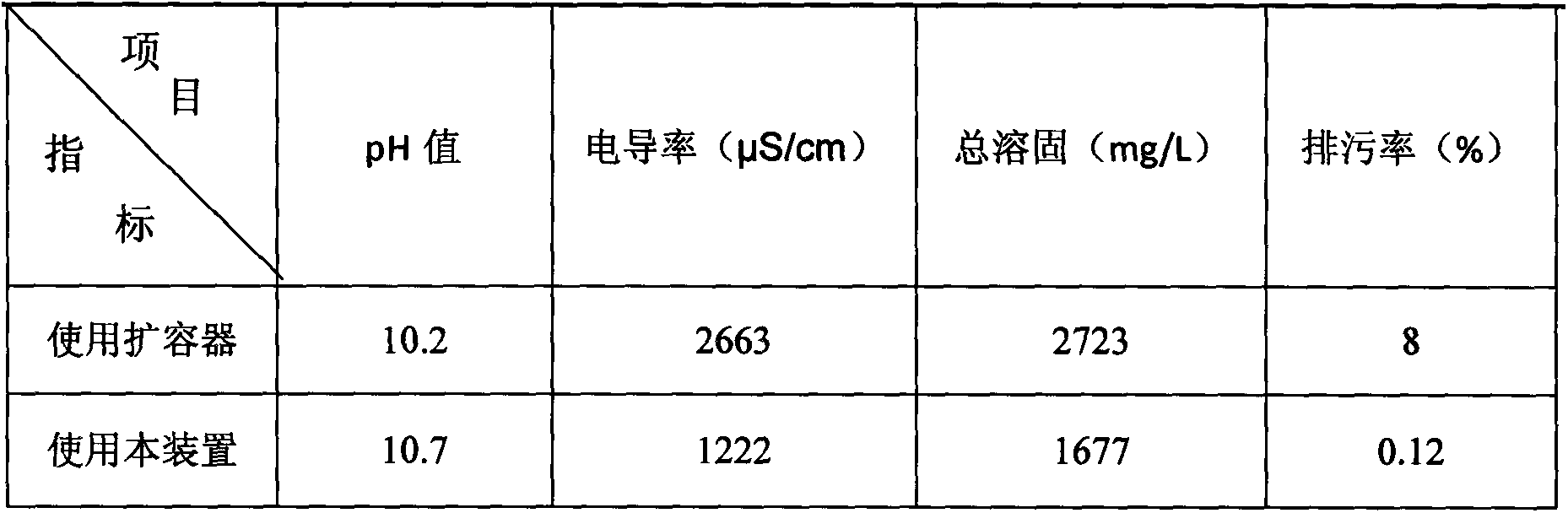

[0016] Example 2 The industrial boiler energy-saving sewage discharge device of the present invention is used to perform sewage treatment on the DZL4-1.25-4 steam boiler of Qingdao Jiarun Chemical Co., Ltd., and it has been operated for 6 months. The before and after effects are compared as follows:

[0017] Table 1 Comparison of the use effect between the industrial boiler energy-saving sewage discharge device of the present invention and existing equipment

[0018]

[0019] Conclusions: 1. The boiler water quality has improved rapidly, the steam production of the boiler has increased from 3.1 tons per hour to 3.8 tons, and the heat transfer effect has been significantly improved; 2. The amount of sewage has been reduced, resulting in a significant reduction in water replenishment, and the water saving rate has increased by more than 98%. .

Embodiment 3

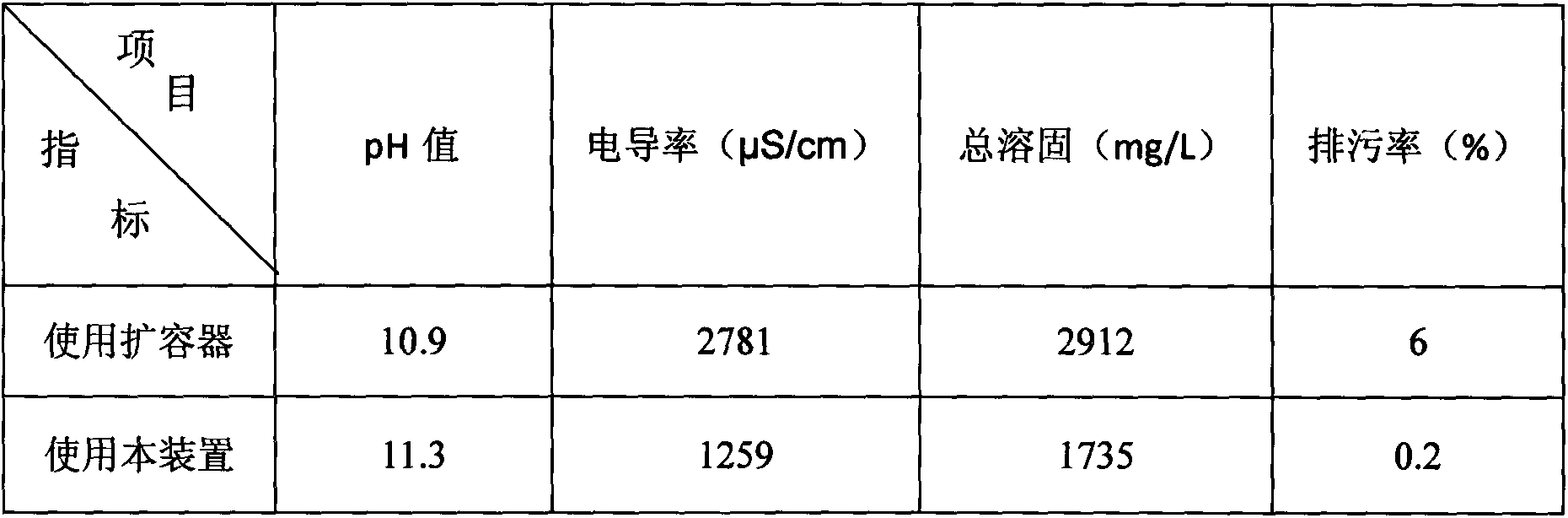

[0020] Example 3 The comparison of the effect of sewage treatment on the alkali recovery boiler WGZ1.27--26 of Shandong Bohui Company using the industrial boiler energy-saving sewage discharge device of the present invention is as follows:

[0021] Table 2 The use effect comparison between the industrial boiler energy-saving sewage discharge device of the present invention and existing equipment

[0022]

[0023] Conclusions: 1. The original boiler water was turbid, and white suspended matter was clearly observed visually. After using this equipment, the water quality was quickly clarified, and all indicators were reduced and improved, ensuring the safe operation of the boiler. The steam production rate was changed from the original 17 tons / hour, increased to 21 tons / hour, significantly improving heat exchange efficiency; 2. Reduced sewage discharge, reduced water replenishment, and a water saving rate of over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com