Light low cost durable cable bridge

A cable tray and low-consumption technology, which is applied in the field of light-weight, low-consumption and durable cable trays, can solve problems such as prone to pressure sinking, complex structure of the bridge frame, and easy to rust, so as to reduce production costs, avoid pressure sinking, and avoid corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

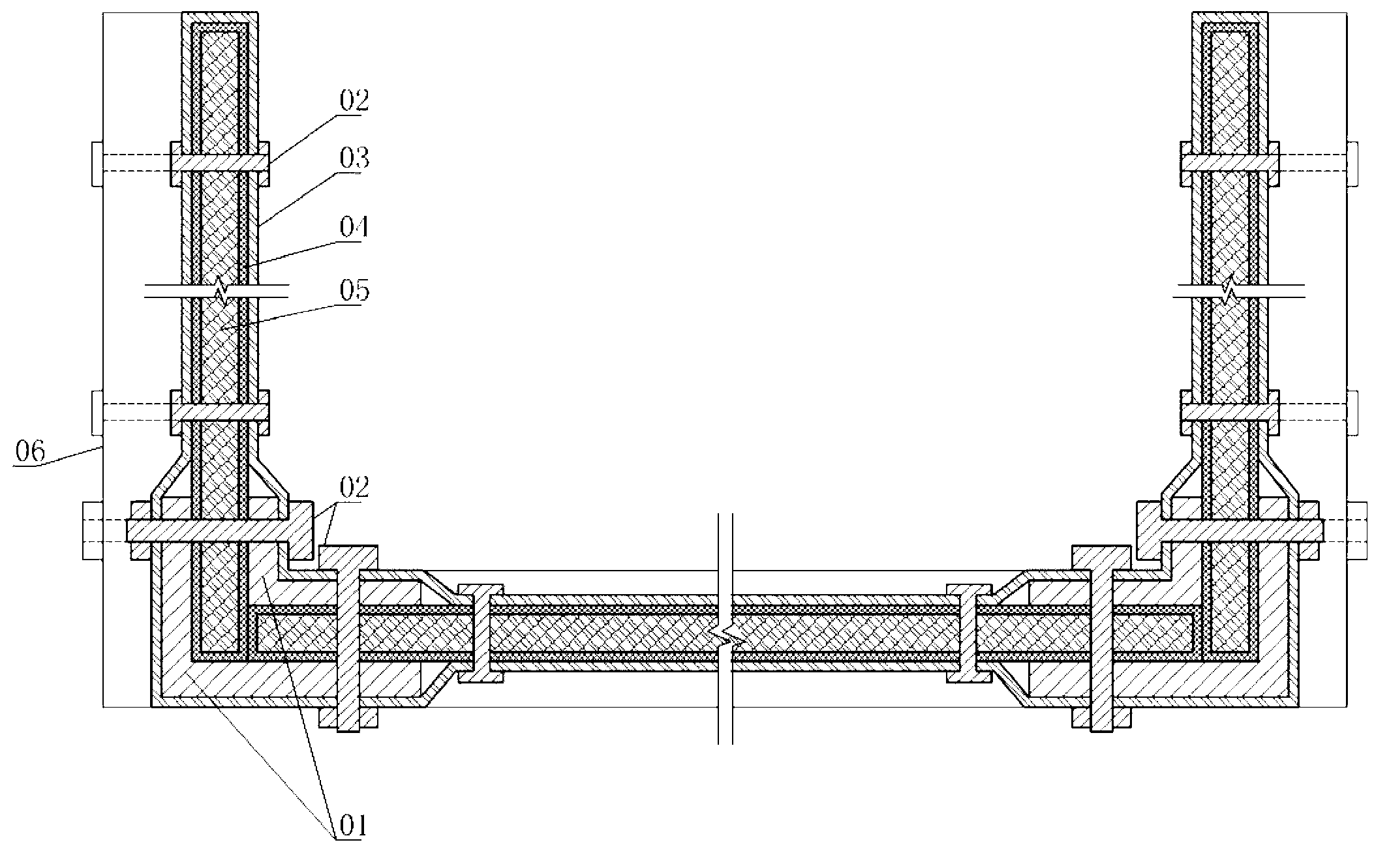

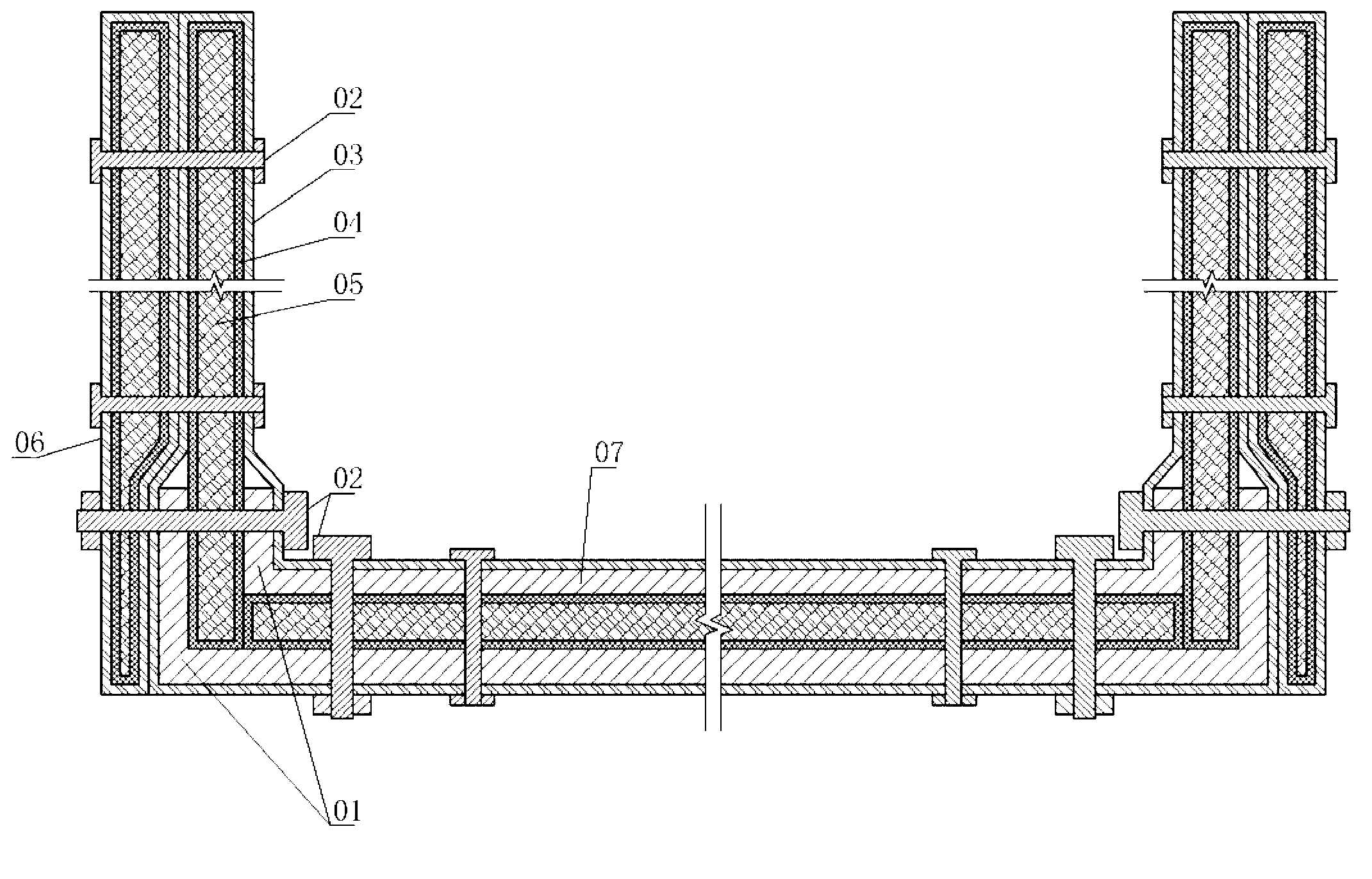

[0018] The light-weight, low-consumption and durable cable tray is composed of plate card 01, bolt 02, tin plate 03, waterproof coating 04, bamboo board 05, structural column 06 and transverse rib 07. Wherein, the surface of the bamboo board 05 is coated with one deck of waterproof paint 04. Board 01 is a pair of L-shaped angle steels of different sizes. The two angle steels overlap each other to form a fixing piece with an L-shaped groove. The L-shaped groove in each fixing piece consists of two vertical and horizontal Slot composition. A pair of horizontal slots of the fixing parts are arranged facing each other. The two ends of the bamboo board 05 with a thickness of not less than 60mm are respectively inserted into the horizontal slots of the pair of fixing parts and fixed by bolts, and each vertically arranged bamboo board 05 has a thickness of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com