Maglev zero-stiffness vibration isolator and vibration isolation system with two-dimensional flexible hinge angle decoupling

A technology of flexible hinges and vibration isolators, applied in spring/shock absorbers, vibration suppression adjustment, non-rotational vibration suppression, etc. Coupling and other problems, to achieve high load capacity, to solve the effect of friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

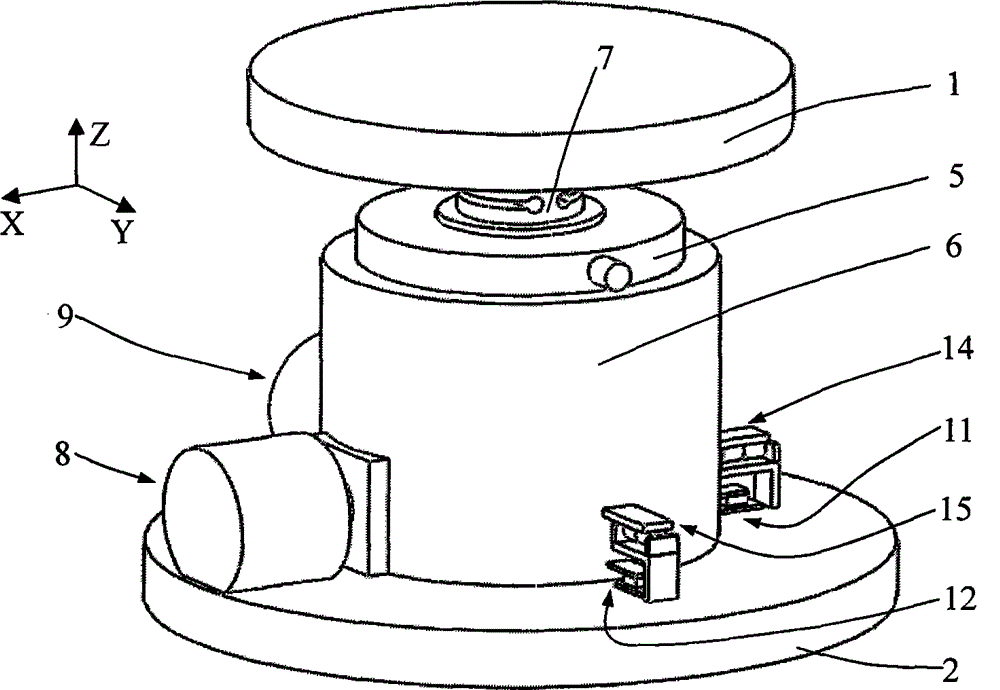

[0032] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings.

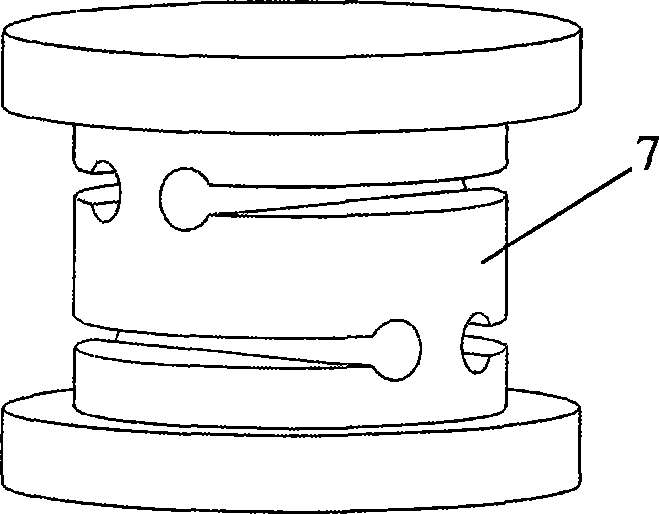

[0033] A maglev zero-stiffness vibration isolator with two-dimensional flexible hinge angle decoupling, consisting of an upper mounting plate 1, a lower mounting plate 2, a clean compressed air source 3, an air pipe 26 and a vibration isolator body 4, the vibration isolator body 4 is installed Between the upper mounting plate 1 and the lower mounting plate 2, the clean compressed air source 3 is connected to the vibration isolator main body 4 through the air pipe 26. The structure of the vibration isolator main body 4 is: the lower surface of the sleeve 6 and the lower mounting plate 2 Lubricated and supported by the magnetic thrust bearing 24, the piston barrel 5 is mounted upside down in the sleeve 6, and is lubricated and supported with the sleeve 6 through the radial bearing cylindrical air bearing surface 22, and the two-dimensional flexible hinge 7 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com