Coplane air floatation orthogonal decoupling and flexible membrane angle decoupling zero-stiffness vibration isolator

A vibration isolator and flexible membrane technology, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, bearing, etc., can solve the problem of high angular stiffness and natural frequency, prone to chord-membrane resonance, and poor positioning accuracy of air spring vibration isolators and other problems, achieve high positioning accuracy, good decoupling effect, and solve the effect of low positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

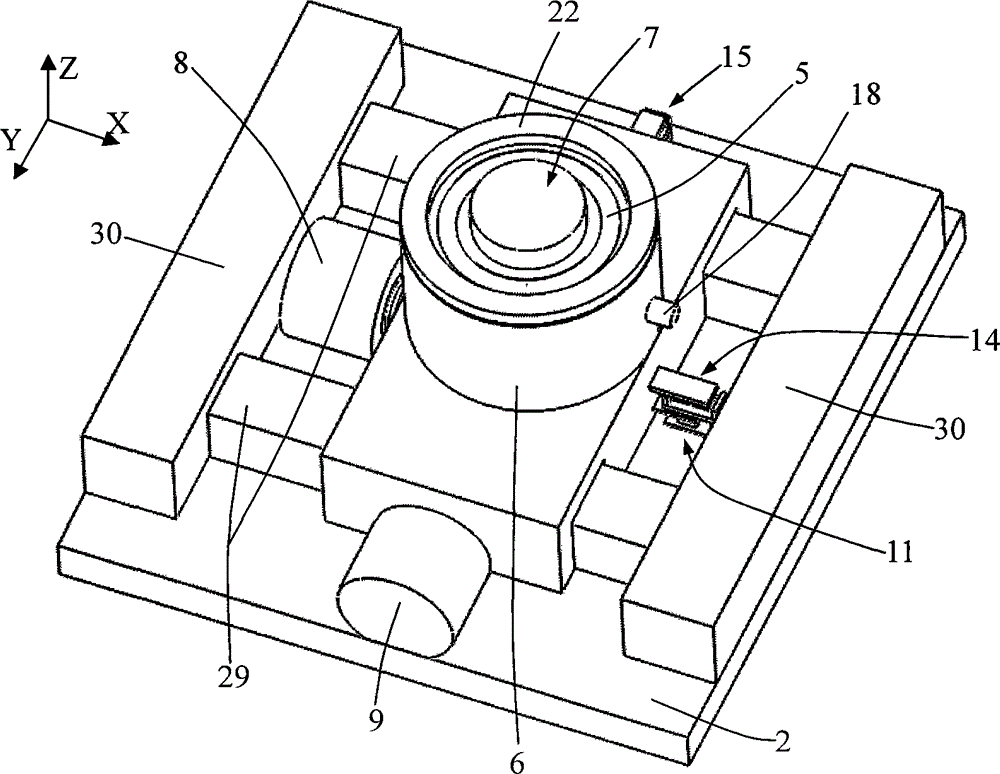

[0032] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings.

[0033] A zero-stiffness vibration isolator with coplanar air floatation orthogonal decoupling and flexible membrane angle decoupling, consisting of an upper mounting plate 1, a lower mounting plate 2, a clean compressed air source 3, an air pipe 26 and a vibration isolator body 4, The vibration isolator main body 4 is installed between the upper mounting plate 1 and the lower mounting plate 2, and the clean compressed air source 3 is connected to the vibration isolator main body 4 through the air pipe 26. In the structure of the vibration isolator main body 4, the sleeve 6 The lower surface and the lower mounting plate 2 are lubricated and supported by the axial bearing plane air bearing surface 21, the flexible membrane 5 is installed on the upper end of the sleeve 6, and is pressed and sealed by the pressure ring 22, the upper pressure plate 7a of the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com