Continuous railroad bed compaction quality monitoring and controlling system and working method

A technology for compaction quality and railway subgrade, applied in the direction of roads, roads, road repair, etc., can solve the problems of inability to realize real-time control of the rolling process, no clear requirements, and time-consuming and labor-intensive point-by-point testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

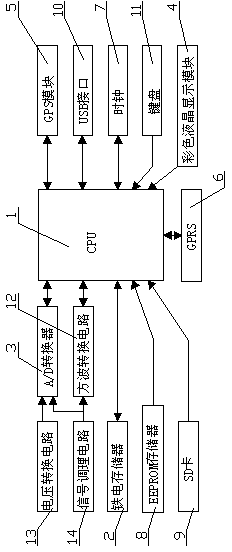

[0073] A railway subgrade continuous compaction quality monitoring and control system, its composition includes: single-chip microcomputer 1, described single-chip microcomputer is respectively connected with ferroelectric memory 2, A / D converter 3, color liquid crystal display circuit 4, GPS module 5, GPRS module 6, clock chip 7, EEPROM 8, SD card 9, USB interface circuit 10, keyboard circuit 11, square wave conversion circuit 12 are connected, and described A / D converter and voltage conversion circuit 13, The signal conditioning circuit 14 is connected, and the square wave conversion circuit is connected with the signal conditioning circuit.

[0074] The railway subgrade continuous compaction quality monitoring and control system comprises: RAM series single-chip microcomputer (STM32F103VET6), single-chip microcomputer and ferroelectric RAM memory (FM22L16), analog / digital converter through data bus, address bus and control bus form respectively (ADS8364), color liquid cryst...

Embodiment 2

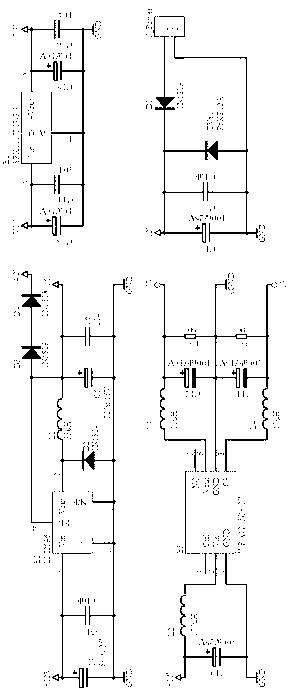

[0078] According to the railway subgrade continuous compaction quality monitoring and control system described in embodiment 1, as attached figure 1The signal conditioning circuit shown in the figure filters the input acceleration signal to remove interference, and then performs linear conversion to meet the requirements of the A / D conversion for the amplitude range of the input signal. The signal conditioning circuit and the A / D converter are under the control of the CPU. , collect the acceleration signal, and calculate the vibration compaction value according to the relevant vibration compaction process parameters of the vibratory roller VCV , and then use the vibration compaction value VCV Monitor and control the subgrade compaction process. The voltage conversion circuit part linearly transforms the working voltage of the device to meet the requirements of the A / D conversion for the input signal amplitude range. The voltage conversion circuit part and the A / D converter m...

Embodiment 3

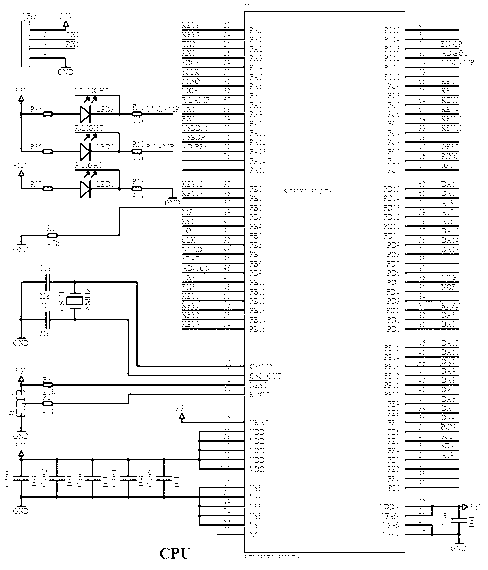

[0080] According to the railway subgrade continuous compaction quality monitoring and control system described in Embodiment 1, the attached figure 2 CPU (single-chip microcomputer) part of the circuit diagram. The CPU part is the core part of the railway subgrade continuous compaction quality monitoring and control system. figure 2 51~54, 63~66, and pins of U1 are respectively connected with Figure 9 The 1-8 pins of J-KEY1LAMP are connected. figure 2 The 23, 24, 33-36 pins of U1 are respectively connected with Figure 9 1-6 pins of J-KEY2 are connected. figure 2 Pins 61, 62, 81, 82, 38-41 of U1 are connected with Figure 10 2-9 pins of U5, 7-10, 13-16 pins of U7 and Figure 14 The 48-41 pins of U8 are connected.

[0081] figure 2 The 42-46, 55-57 pins of U1 are respectively connected with Figure 10 2-9 pins of U6, 29-32, 35-38 pins of U7 and Figure 14 The 40-33 pins of U8 are connected. figure 2 Pins 58-60, 85, and 86 of U1 are connected to and Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com