Transmission structure of spiral spreading machine distributor

A technology of screw distributor and transmission structure, which is applied to roads, road repair, roads, etc., can solve the problems of inflexible loading and unloading, inconvenient production and maintenance, and poor anti-segregation effect, and achieves stable and reliable transmission effect. Simple structure and low assembly process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

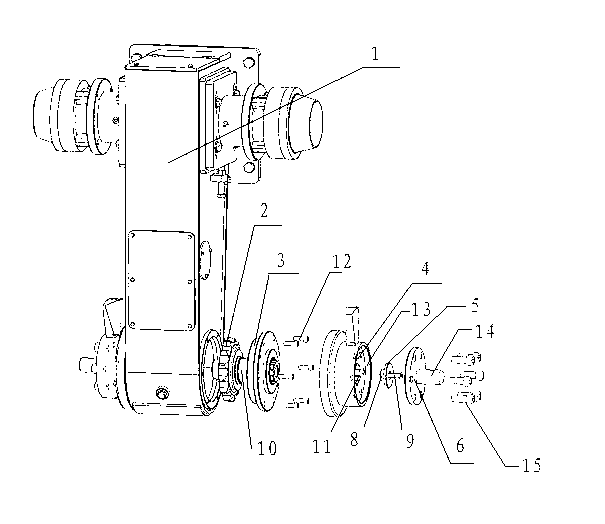

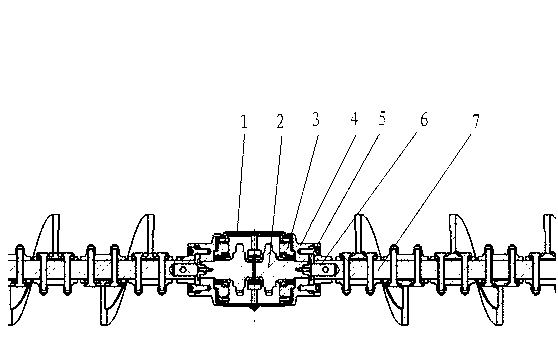

[0024] As shown in the figure, a transmission structure of a paver spiral distributor includes a spiral material distribution box 1, a driving wheel and a driven wheel 2 driven by the driving wheel are arranged inside the spiral material distribution box, and the driven wheel 2 passes through the bearing Installed in the spiral distribution box, the right part of the driven wheel is provided with a bearing end cover 3, a joint 4, an end plate 5, a main shaft fixed body 6, and a screw shaft 7, and the bearing end cover is fixedly connected to the spiral distribution box Above, the left end surface of the bearing end cover presses the driven wheel, and the driven wheel drives the joint to rotate. The end plate is provided with an embedded section 8 embedded in the driven tooth and a limiting section 9 for axially limiting the joint. The main shaft fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com