Feed plate of fiber rod opening device of free end spinning machine

A technology for feeding cotton sheets and fiber strips, which is applied in the directions of open-end spinning machines, spinning machines, and continuously wound spinning machines to achieve the effect of fixing, reducing structural costs, and cheap fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

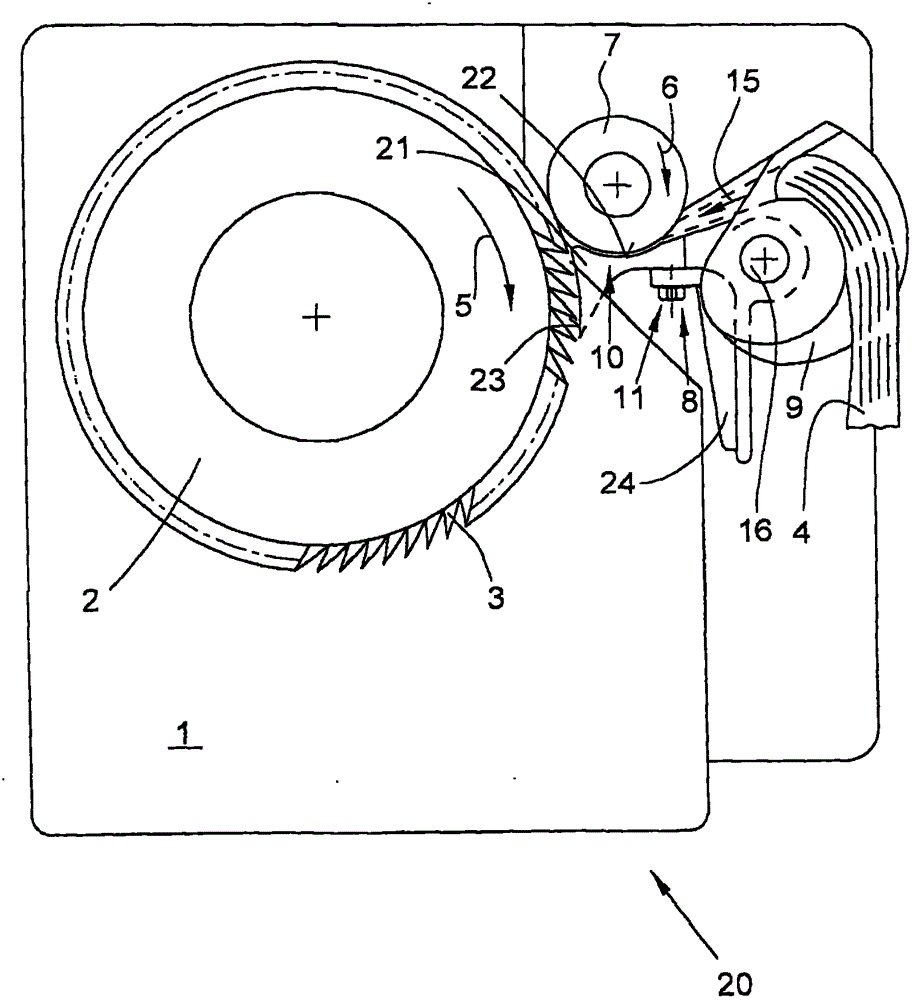

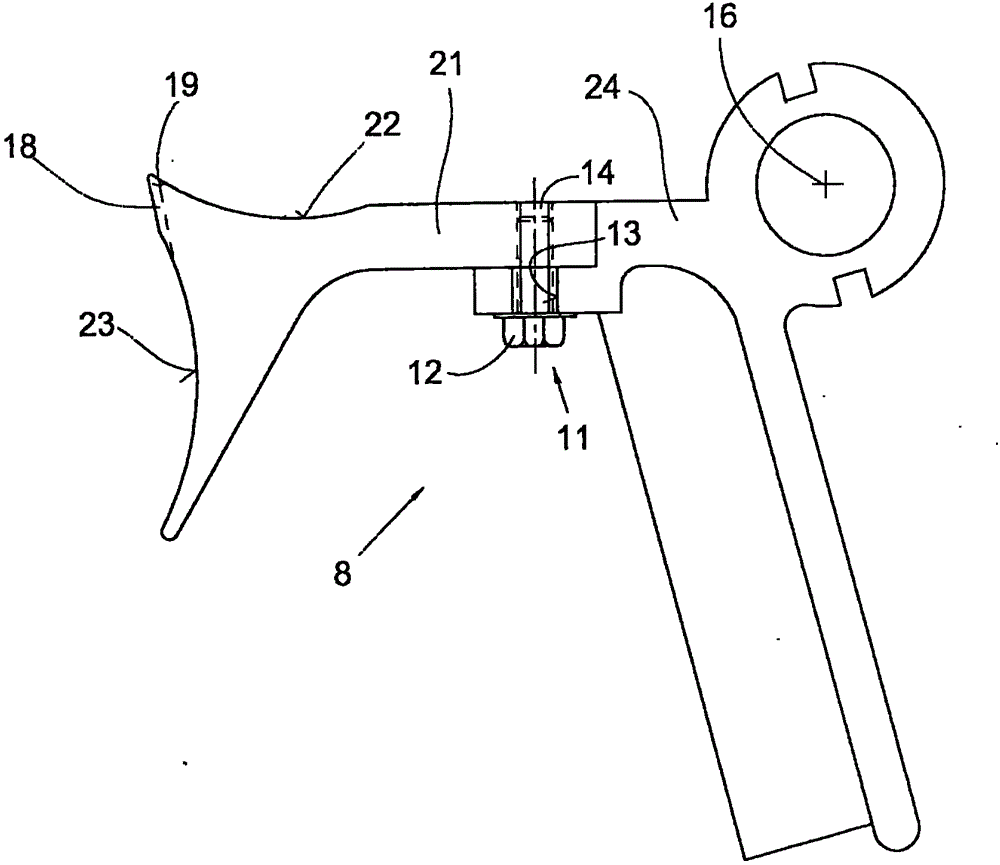

[0024] figure 1 The opening roller housing 1 of the sliver opening device, generally designated 20, of an open-end spinning machine (known and not further shown) is shown. An opening roller 2 is rotatably mounted in the opening roller housing 1, which rotates in the direction of the arrow 5 during spinning operation and has a so-called opening roller clothing 3 on its periphery for carding Feed the fiber bar 4. Furthermore, a fiber sliver feed roller 7 rotatable in the direction of the arrow 6 and an associated feed plate 8 are mounted in or on the opening roller housing 1 . Such as figure 1 As shown, the feed fiber sliver 4 that is usually stored in a spinning barrel not shown is guided via the fiber sliver compactor 9 in the direction of the arrow 15 into the clamping area 10, which is formed by the feeding plate 8 and the fiber sliver Feed to Lola 7 composition. Here, a spring element (not shown) presses the feed plate 8 in the direction of the sliver feed roller 7, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com