Locking synchronizing module of shift transmission, as well as method for shifting shift transmission with lock synchronizing module

A technology for synchronizing components and transmissions, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve problems such as difficulty, cost, and high cost, and achieve the effect of low structural cost and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

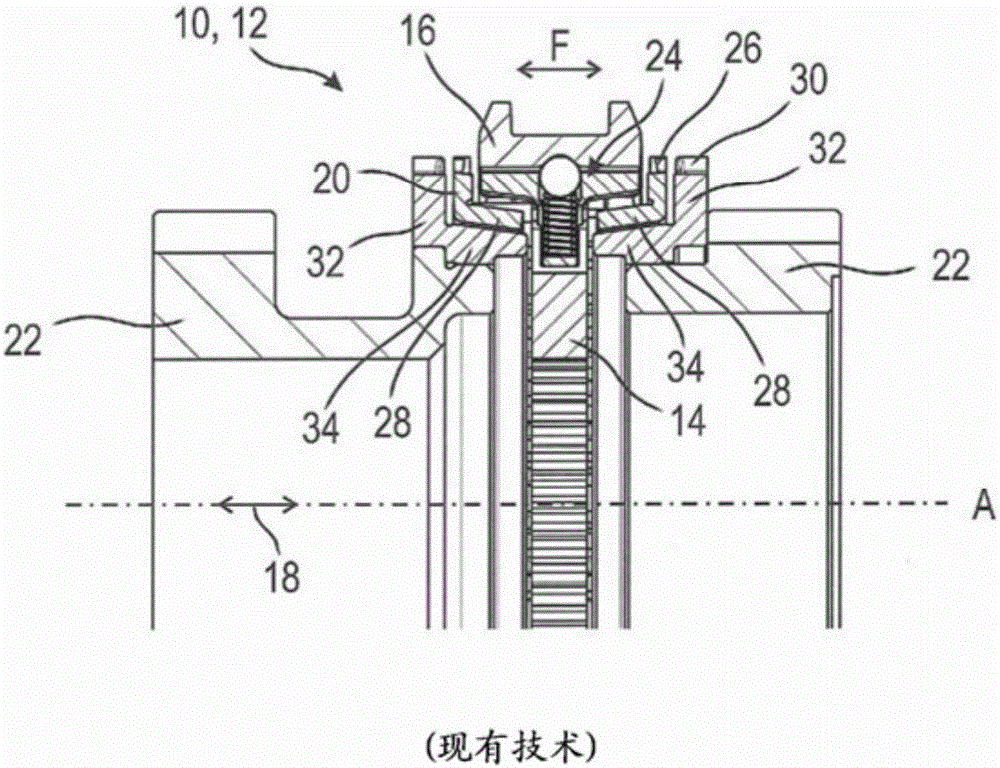

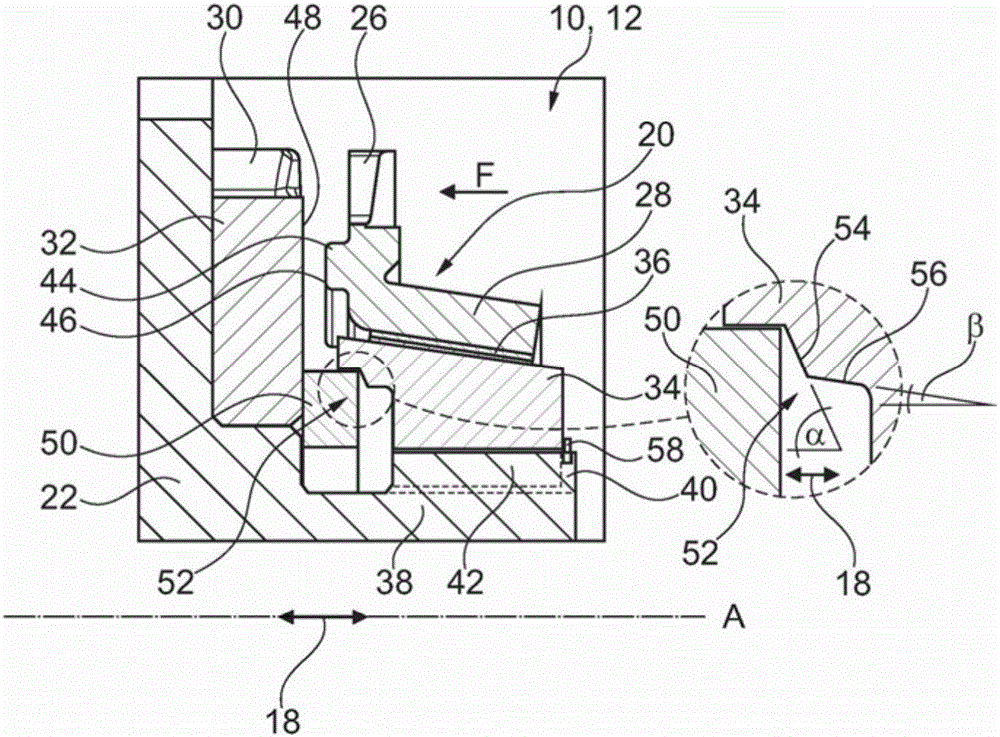

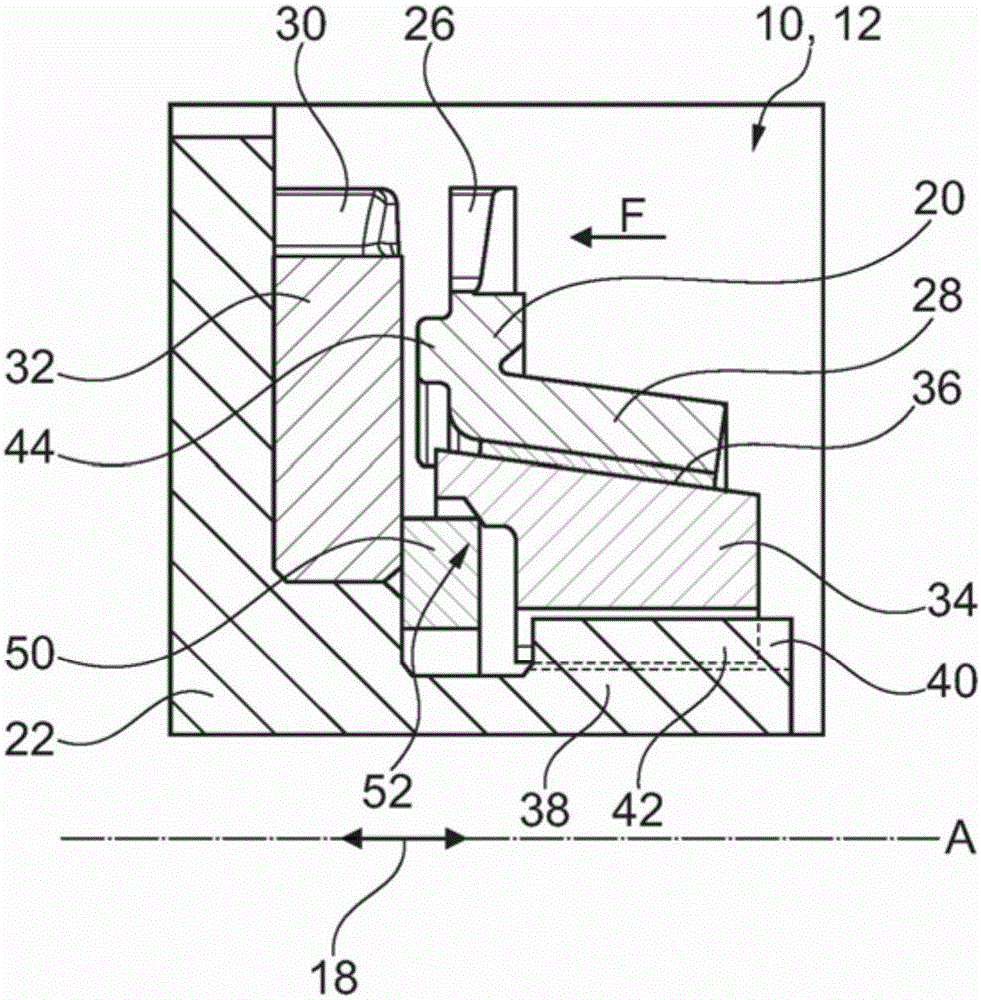

[0036] figure 1 A conventional shift transmission 10 for a vehicle is shown in the region of the lock-up synchronizer assembly 12 known from the prior art. The locking synchronizing unit 12 comprises: a synchronizing hub 14 , which is mounted in a rotationally fixed manner on the transmission shaft and rotates in the circumferential direction about the transmission axis A; The shifting sleeve is arranged displaceably in the axial direction 18 relative to the synchronizing hub 14 ; the synchronizing ring 20 is used to couple the synchronizing hub 14 to the shifting gear 22 of the shifting transmission 10 via a frictional connection and a presynchronization unit 24 which engages on the shifting sleeve 16 and acts on the synchronizing ring 20 towards the axial shifting of the shifting gear 22 to be coupled when the shifting sleeve 16 moves axially Force F.

[0037] The synchronizer ring 20 has a locking toothing 26 and a friction cone 28 which according to figure 1 Formed as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com