Voltage type adhesive tape running speed and slip detection device and detection method

A technology of running speed and detection device, which is applied in the direction of transportation and packaging, conveyor control devices, conveyors, etc., can solve the problems of belt running speed and inaccurate slip detection, and achieve real and reliable belt speed, wide application range and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

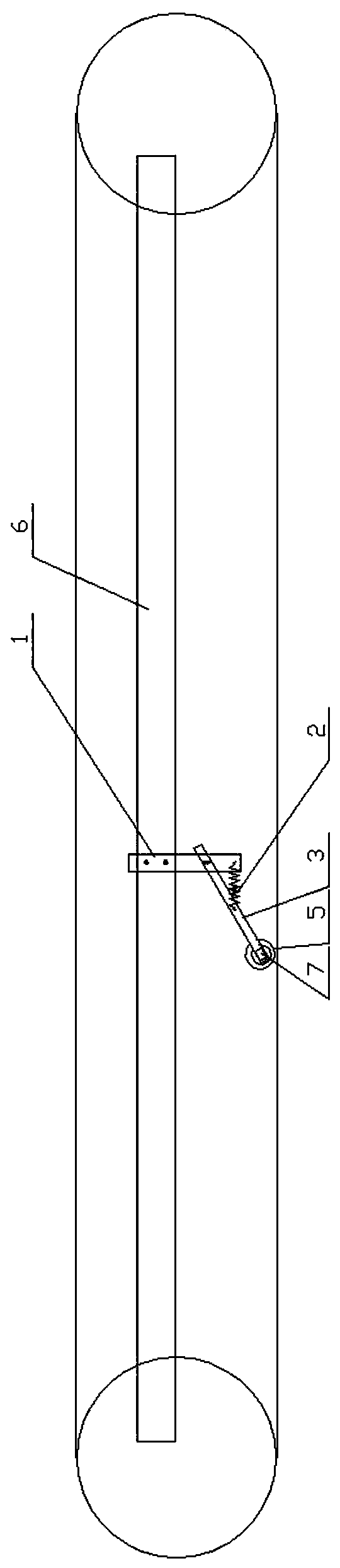

[0052] A voltage-type tape running speed and slip detection device is composed of a fixed column 1, a tension spring 2, a movable arm 3, a transmission shaft 4, a passive friction wheel 5, a voltage-type detection unit 7 and an alarm device. The fixed column 1 Fixedly connected on the tape machine frame 6, the middle part of the fixed column 1 is hinged with one end of the movable arm 3, one end of the tension spring 2 is fixed at the bottom of the fixed column 1, and the other end is fixed at the middle part of the movable arm 3, and the passive friction The wheel 5 is connected to the other end of the movable arm 3 through the transmission shaft 4, and the passive friction wheel 5 is in frictional contact with the tape, and the voltage detection unit 7 is fixedly connected to the movable arm 3, and is fixedly connected to one end of the transmission shaft 4;

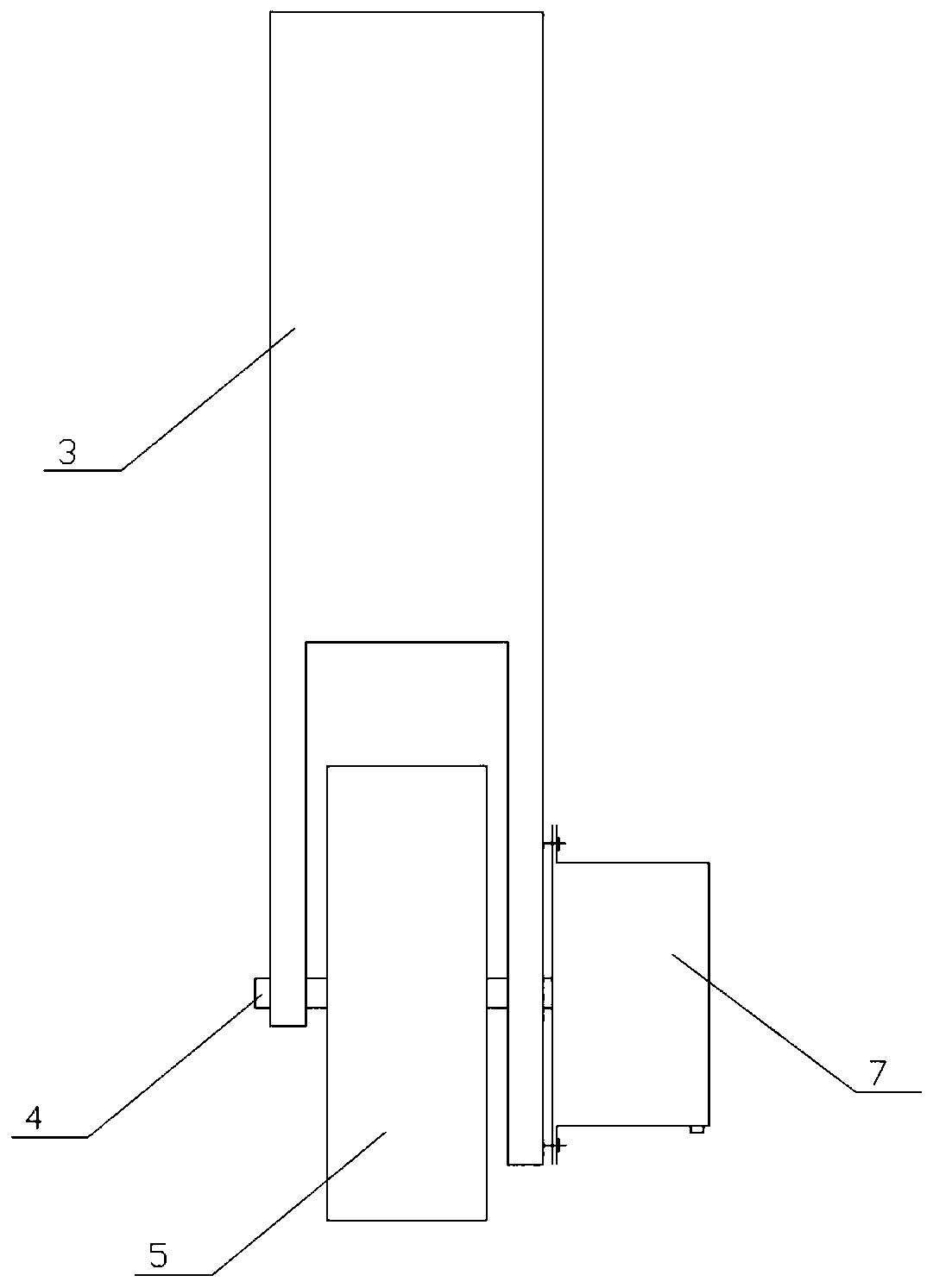

[0053]Described voltage detection unit is made up of box body 71, active large gear 72, passive pinion 73, generator ...

Embodiment 2

[0056] A method for detecting the running speed of an adhesive tape, using the voltage-type adhesive tape running speed and slip detection device of Embodiment 1, comprising the following steps:

[0057] 1) Turn on the tape machine and the detection device, and the host computer receives the voltage signal from the generator in the device;

[0058] 2) The upper computer calculates the actual running speed of the tape of the tape machine according to formula 5;

[0059] The calculation principle is:

[0060] The tape to be monitored is in close contact with the passive friction wheel in the device, and is driven by friction, so the actual running speed of the tape is S 胶 The linear speed S of the contact point between the passive friction wheel and the tape 线 equal, according to the radius R of the passive friction wheel 摩 The speed N of the passive friction wheel can be calculated 摩 ,which is:

[0061] S 胶 = S 线 =0.002πR 摩 N 摩 (1)

[0062] In the formula, S 胶 : The...

Embodiment 3

[0082] A method for detecting tape slippage, using the voltage-type tape running speed and slip detection device of embodiment 1, comprising the steps of:

[0083] 1) Set the running speed of the tape machine during normal operation in the upper computer, and receive the voltage signal sent by the generator in the device;

[0084] 2) Use the host computer to monitor the actual running speed of the tape corresponding to the received voltage signal and set the running speed of the tape;

[0085] 3) Monitoring alarm

[0086] When the tape frequency is running:

[0087] When the running speed of the tape is lower than 95% of the rated speed of the tape, it means that the tape is slipping, and the upper computer notifies the alarm device to alarm;

[0088] When the tape frequency is running:

[0089] When the running speed of the tape is lower than 95% of the given speed of the tape, it means that the tape is slipping, and the upper computer notifies the alarm device to alarm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com