Method for synthesizing liquid hydrocarbons

A technology for liquid hydrocarbons and synthesis gas, which is used in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems that parallel reactors cannot control the reaction depth in stages and the total pressure drop of series reactors, etc., and achieves a small pressure drop. , high activity and selectivity, avoiding the effect of large total pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

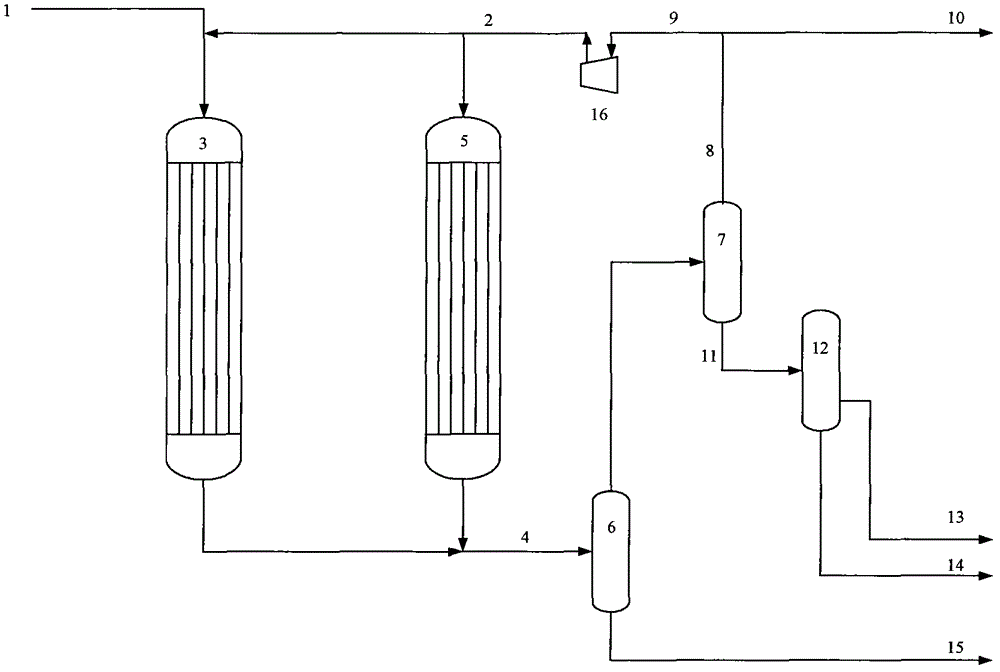

[0024] The preparation process of the Fischer-Tropsch synthesis catalyst used in the examples is as follows: take alumina powder, add distilled water dropwise to incipient wetness, record the volume of consumed water, then calculate according to the Co content (oxide) 27% by weight, prepare the Cobalt nitrate impregnation solution. Then impregnate alumina with this solution to incipient wetness, let it stand for 8 hours, then dry it at 120°C for 4 hours, and bake it in a muffle furnace at 450°C for 4 hours to prepare the catalyst. The particle size range of the catalyst is 1.5-2.5mm. This embodiment adopts the technological process shown in the accompanying drawing. The catalyst volume ratio of the first stage reactor to the second stage reactor catalyst volume is 1:1. The fresh feed gas was reacted under the process conditions listed in Table 1.

[0025] Table 1 process conditions

[0026] Process conditions

[0027] By adopting the method provided by the invent...

Embodiment 2

[0029]The preparation process of the Fischer-Tropsch synthesis catalyst used in the examples is as follows: take alumina powder, add distilled water dropwise to incipient wetness, record the volume of consumed water, then calculate according to Co content (oxide) 32% by weight, prepare Cobalt nitrate impregnation solution. Then impregnate alumina with this solution to incipient wetness, let it stand for 8 hours, then dry it at 120°C for 4 hours, and bake it in a muffle furnace at 450°C for 4 hours to prepare the catalyst. The particle size range of the catalyst is 1.5-2.5 mm. This embodiment adopts the technological process shown in the accompanying drawing. The catalyst volume ratio of the first stage reactor to the second stage reactor catalyst volume is 1:1.2. The fresh feed gas was reacted under the process conditions listed in Table 2.

[0030] Table 2 process conditions

[0031] Process conditions

[0032] By adopting the method provided by the invention, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com