Method for preparing saponin by vacuum digestion

A technology of vacuum extraction and saponin, applied in the fields of biomass chemical industry and applied chemistry, to achieve the effects of low energy consumption for extraction and concentration, accelerated liquid phase mass transfer rate, and improved product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

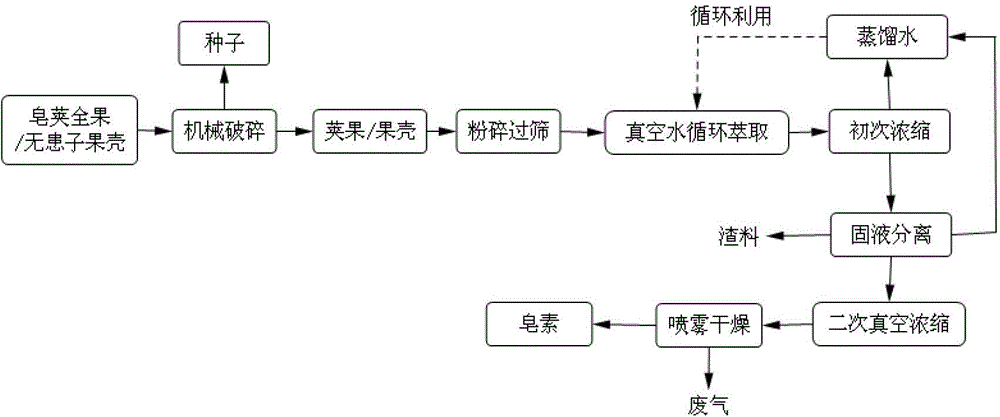

[0062] Such as figure 1 As shown, the specific process of the method for preparing saponin by leaching under a vacuum of 0.05 to 0.07Mpa according to the present invention is as follows:

[0063] (1) Raw material pretreatment;

[0064] Acacia pods are used as saponin raw materials, sorted, crushed and sieved, and set aside.

[0065] (2) Vacuum water circulation extraction;

[0066] When extracting, the mass ratio of saponins pods to water is 1:15, and the system is heated. When the system temperature reaches 45°C, vacuumize. When the vacuum degree of the system reaches 0.07MPa and is stable, continue to heat until the temperature is stable at 55°C. At this time, the water in the system is in a boiling state, and the water vapor is condensed and refluxed into the system, and vacuum refluxed for leaching for 3 hours.

[0067] (3) initial concentration;

[0068] After the vacuum water circulation extraction is completed, maintain the heating temperature and vacuum of the sys...

Embodiment 2

[0076] Such as figure 1 As shown, the specific process of the method for preparing saponin by leaching under a vacuum of 0.05 to 0.07Mpa according to the present invention is as follows:

[0077] (1) Raw material pretreatment;

[0078] Sapindus husk is used as saponin raw material, after sorting, crushing and sieving, it is ready for use.

[0079] (2) Vacuum water circulation extraction;

[0080] During extraction, the mass ratio of Sapindus husk to water is 1:15, and the system is heated. When the system temperature reaches 45°C, vacuumize. When the vacuum degree of the system reaches 0.07MPa and is stable, continue to heat until the temperature is stable at 50°C. At this time, the water in the system is in a boiling state, and the water vapor is condensed and refluxed into the system, and vacuum refluxed for 3 hours.

[0081] (3) initial concentration;

[0082] After the vacuum water circulation extraction is completed, maintain the heating temperature and vacuum of the...

Embodiment 3

[0090] Such as figure 1 As shown, the specific process of the method for preparing saponin by leaching under a vacuum of 0.05 to 0.07Mpa according to the present invention is as follows:

[0091] (1) Raw material pretreatment;

[0092] Acacia pods are used as saponin raw materials, sorted, crushed and sieved, and set aside.

[0093] (2) Vacuum water circulation extraction;

[0094] When extracting, the mass ratio of acacia pods to water is 1:10, and the system is heated. When the system temperature reaches 45°C, vacuumize. When the vacuum degree of the system reaches 0.06MPa and is stable, continue heating until the temperature is stable at 52°C. At this time, the water in the system is in a boiling state, and the water vapor is condensed and refluxed into the system, and vacuum refluxed for 1.5h.

[0095] (3) initial concentration;

[0096] After the vacuum water circulation extraction is completed, maintain the heating temperature and vacuum of the system and continue h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com