Preparation method for special slow-release long-acting compound fertilizer for corn

A special technology for compound fertilizer and corn, which is applied in the direction of fertilizer mixture, application, fertilization device, etc., can solve the problems of waste of resources, soil pollution, low nitrogen utilization rate, etc., to improve yield and quality, save phosphate rock resources, and use fertilizer efficiently high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Prepare slow-release long-acting compound fertilizer special for corn according to the preparation method of the present invention

[0081] Specifically include the following steps:

[0082] ①. Preparation of potassium fertilizer and nitrogen fertilizer compound

[0083] First, after heating and melting 30 parts by weight of urea, add 10 parts by weight of ammonium sulfate and 25 parts by weight of potassium sulfate and mix uniformly to obtain potassium fertilizer and nitrogen fertilizer compound containing potassium, sulfur and ammonium, which are set aside;

[0084] ②. Preparation of mixed phosphate fertilizer

[0085] a. Preparation of apatite powder

[0086] will contain P 2 o 5 10%~20% apatite is ground into powder, the fineness of apatite powder is controlled to 100 mesh ±10, and it is reserved;

[0087] b. mix

[0088] Mix 50 parts by weight of diammonium phosphate, 30 parts by weight of calcium magnesium phosphate and 20 parts by weight of apatite powder p...

Embodiment 2~ Embodiment 7

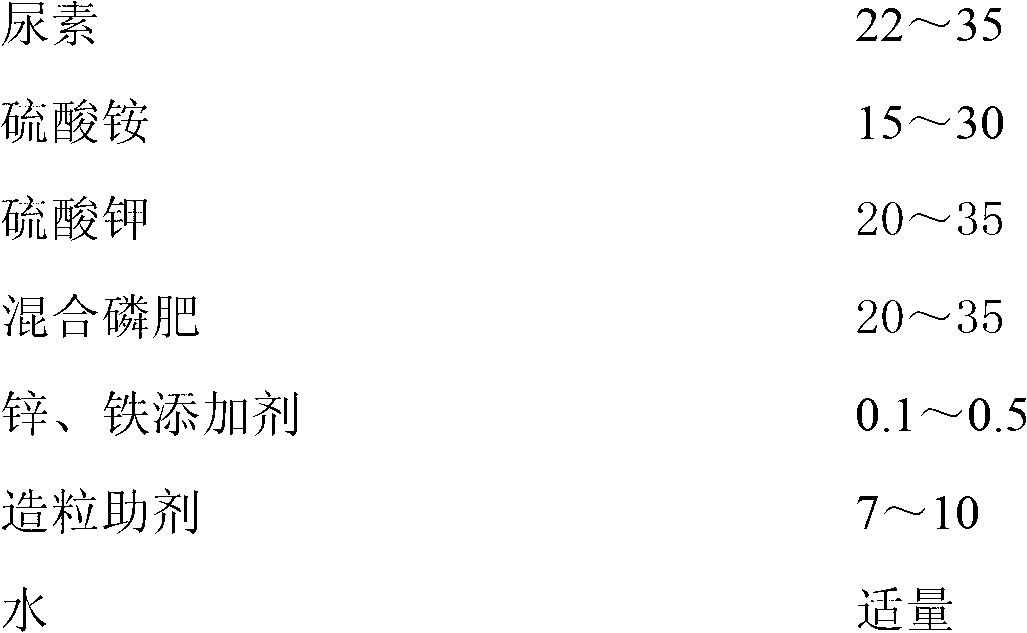

[0108] According to the method and steps of Example 1, prepare the special slow-release long-acting compound fertilizer for corn according to the raw material formula of Table 1

[0109] Table 1

[0110]

[0111] The slow-release long-acting compound fertilizer granules specially made for corn have a round appearance and no peculiar smell;

[0112] The product quality has reached the following technical indicators:

[0113]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com