Method for preparing sodium hydrosulphite from smeltery flue gas

A technology of sodium sulfite and smelting plant, which is applied in the direction of preparation, separation method, chemical instrument and method of alkali metal sulfite, which can solve problems affecting application, increase of production cost, unqualified quality of sodium sulfite products, etc., and achieve reduction of heat load , high purity, and realize the effect of recycling and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

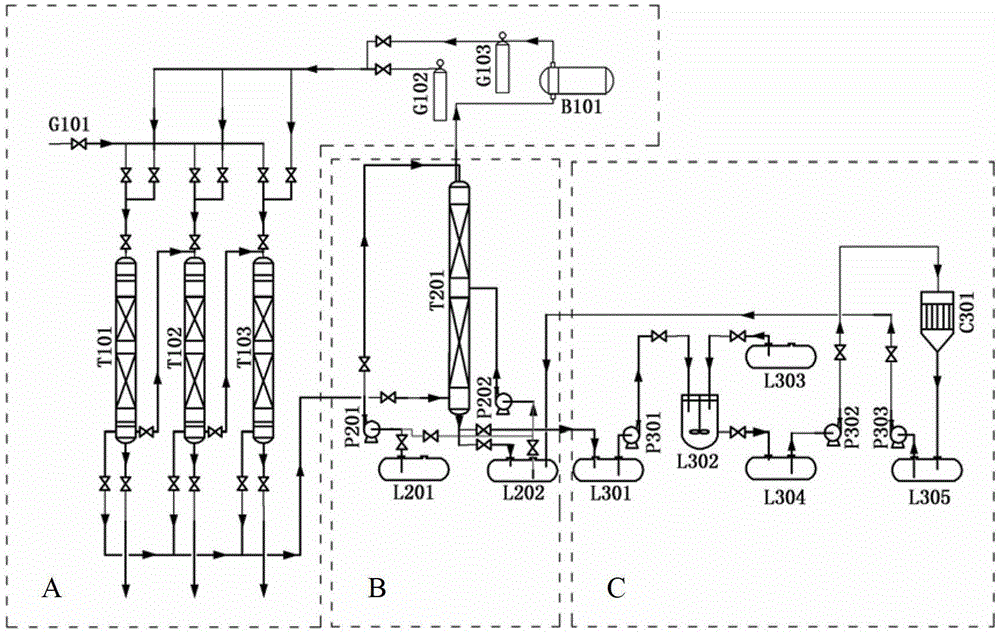

Embodiment 1

[0020] Flue gas composition is 10.0%SO 2 , 5.0%O 2 , and the rest are N 2 , flue gas flow 1m 3 / h, under the condition of normal pressure and 30°C, enter the furnace filled with Ala / γ-Al 2 o 3 The adsorption tower T101 ~ 103 (serial mode). When sulfur dioxide in flue gas selectively adsorbs and penetrates Ala / γ-Al 2 o 3 After the bed, use N 2 Enter the adsorption tower at 30°C to desorb T101-102, and desorb T103 at 50-120°C by temperature programming until it is completely desorbed. The desorbed gas enters the T201 absorption tower and is absorbed countercurrently with the water from the L201 storage tank. After the gas-liquid circulation is established in the absorption tower, the absorption liquid is extracted from the bottom circulating liquid tank L202 and injected into the top and middle of the absorption tower respectively. The ratio of tower top flow to mid-section circulation flow = 1:5, add 45% NaOH solution to L202 to adjust the pH value to 4-5, then put it i...

Embodiment 2

[0022] Flue gas composition is 5.0%SO 2 , 5.0%O 2 , and the rest are N 2 , flue gas flow rate 2m 3 / h, under the condition of normal pressure and 30°C, enter the Ala / γ-Al 2 o 3 The adsorption towers T101~102 (parallel mode) converge and then enter T103 (serial mode), when the sulfur dioxide in the flue gas selectively adsorbs and penetrates Ala / γ-Al 2 o 3 After fixing the bed layer, use N 2 Desorb T101-102 at 30°C, and desorb T103 at 50-120°C by temperature programming until complete desorption. The desorbed gas enters the absorption tower and is absorbed countercurrently with the water from the L201 tank, so that the tower establishes a gas-liquid cycle. The absorption liquid extracted from the circulating liquid tank L202 at the bottom of the absorption tower is poured into the top and middle section of the absorption tower respectively for circulation. The ratio of the flow rate at the top of the tower to the circulation flow in the middle section is 1:3. Add 45% NaO...

Embodiment 3

[0024] Flue gas composition is 1.0%SO 2 , 5.0%O 2, and the rest are N 2 , flue gas flow 3m 3 / h, under the condition of normal pressure and 20°C, enter the Ala / γ-Al 2 o 3 The adsorption and desorption towers T101-102 (parallel mode) converge and then enter T103 (serial mode). When sulfur dioxide in flue gas selectively adsorbs and penetrates Ala / γ-Al 2 o 3 After fixing the bed layer, use N 2 Desorb T101-102 at 30°C, and desorb T103 at 50-120°C by temperature programming until complete desorption. The desorbed gas enters the absorption tower and is absorbed countercurrently with the water from the L201 tank, so that the tower establishes a gas-liquid cycle. The absorption liquid extracted from the circulating liquid tank L202 at the bottom of the absorption tower is poured into the top and middle section of the absorption tower respectively for circulation, the ratio of the flow at the top of the tower to the circulating flow at the middle section is 1:2, and 46% NaOH s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com