Bottle supporting device

A bottle-supporting and bottle-supporting plate technology is applied in the field of bottle-supporting devices of filling machines, which can solve the problems of large occupied space, increased manufacturing cost, difficult maintenance, etc., and achieves the effects of small occupied space, reduced cost, and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

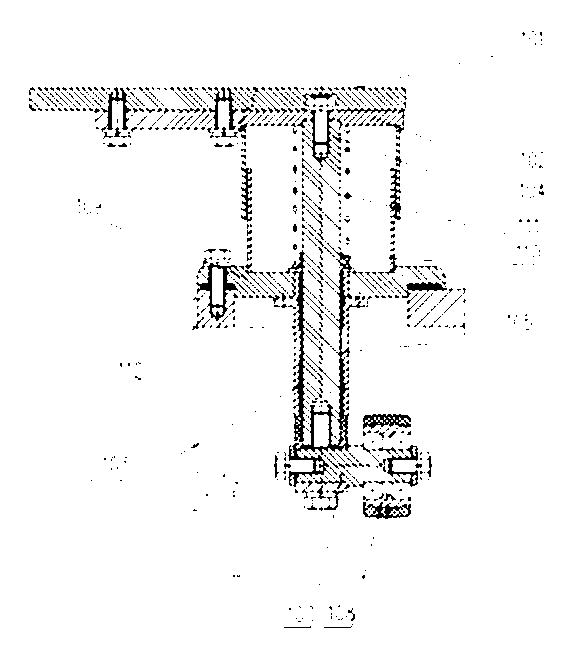

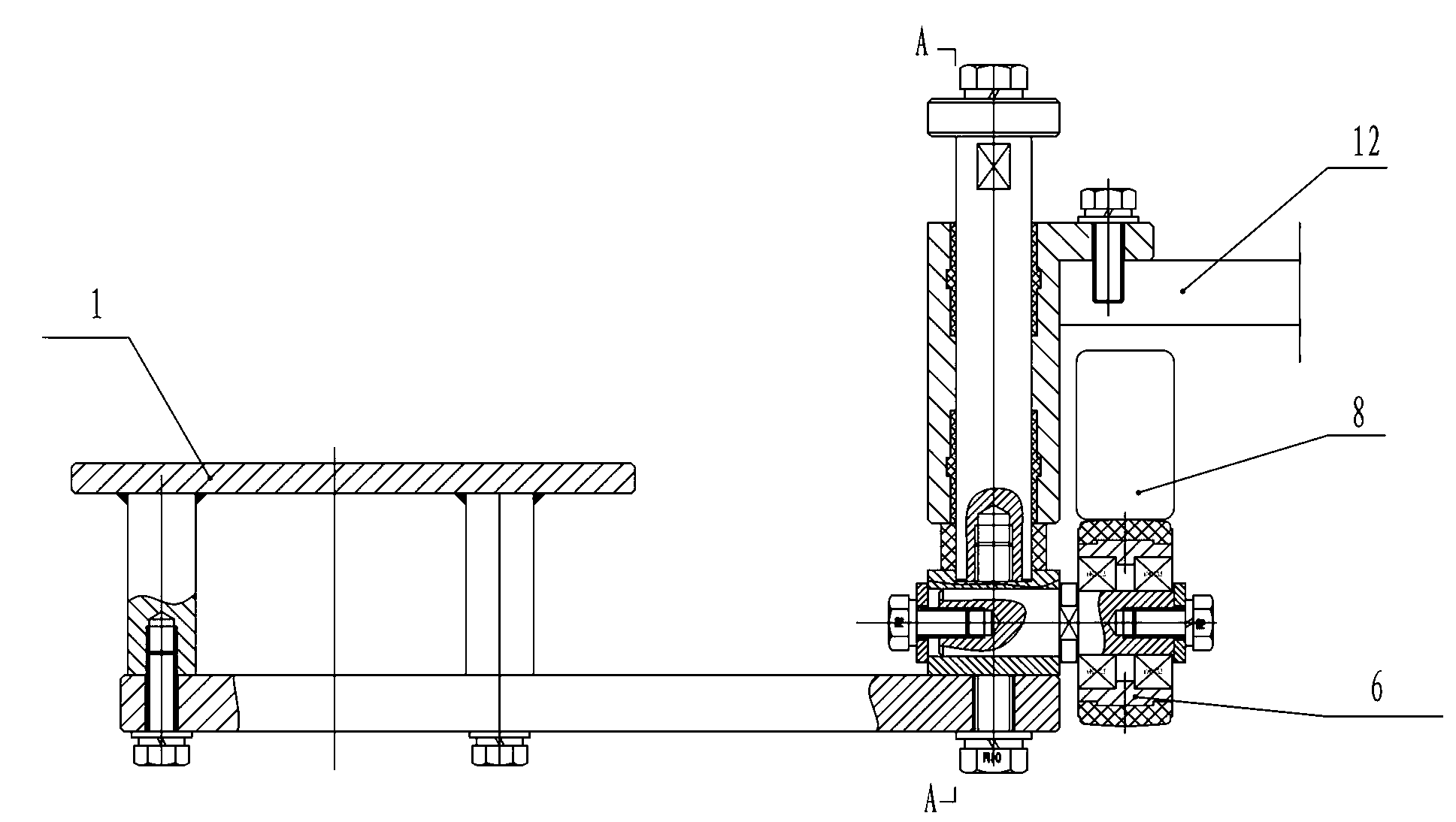

[0011] Embodiment 1: as Figure 3 to Figure 5 As shown, the connecting block 2 that drives the lifting of the bottle support plate 1 is connected to one end of the guide post 4 with the sliding bearing 11 passing through the bearing seat 3, and the other end of the guide post 4 is connected to the limit plate 5 to become one. A lifting device is provided, and the lifting device includes a spring 7 connected between the roller 6 on the connection block 2 and the bearing seat 3 , and the front end of the spring 7 contacts the limit plate 5 . Install the bearing seat 3 on the turntable 12. During the operation of the filling machine, the roller 6 runs on the single guide rail 8 with a height difference. As the trajectory of the guide rail 8 gradually decreases, the roller 6 is pressed down and gradually descends, thereby Drive the guide post 4 to slide downward, and then the guide post 4 drives the bottle support plate 1 to descend. The position plate 5, so the spring 7 is compr...

Embodiment 2

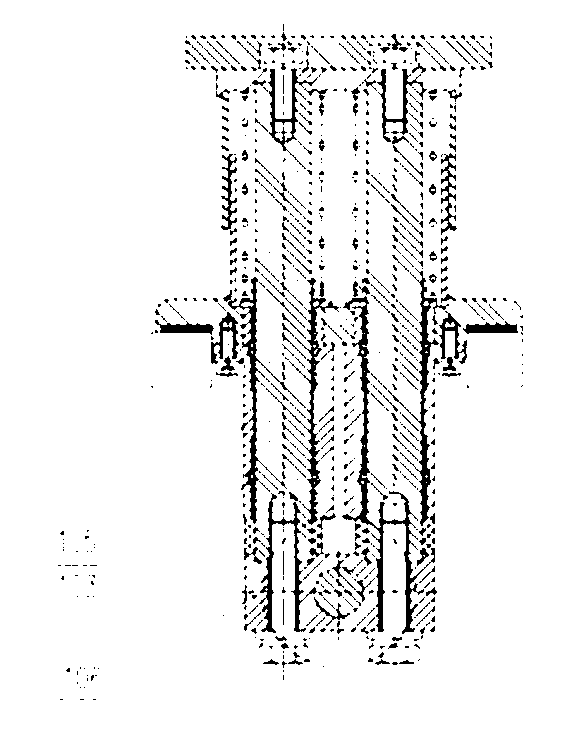

[0014] Embodiment 2: The connection block 2 that drives the bottle support plate 1 up and down is connected to one end of the guide post 4 with the sliding bearing 11 passing through the bearing seat 3, and the other end of the guide post 4 is connected to the limit plate 5 to form one body. The connection block 2 A lifting device is arranged on it, and the lifting device is a roller 6 connected to the connecting block 2 . Install the bearing seat 3 on the turntable 12, the roller 6 moves on the double guide rails, and its upper end and lower end are in contact with the upper guide rail and the lower guide rail with a height difference respectively, and the curve trajectory of the upper guide rail and the lower guide rail is the same. In the middle, as the trajectory of the guide rail gradually decreases, the roller 6 is gradually lowered by the pressure of the upper guide rail, thereby driving the guide column 4 to slide downward, and then the guide column 4 drives the bottle ...

Embodiment 3

[0015] Embodiment 3: The connection block 2 that drives the bottle support plate 1 to lift is connected to one end of the guide post 4 with the sliding bearing 11 passing through the bearing seat 3, and the other end of the guide post 4 is connected to the limit plate 5 to form one body. The connection block 2 A lifting device is arranged on the top, and the lifting device includes a roller 6 connected to the connecting block 2. The lower end of the roller 6 contacts the highest position of the edge of the cam. The cam is connected to the stepping motor, and the bearing seat 3 is installed on the turntable 12. Drive the cam to rotate. When the highest position of the cam edge touches the roller 6, the roller 6 is raised, so that the connecting block 2 rises, and then drives the guide post 4, the limit plate 5 and the bottle support plate 1 to rise; when the cam rotates to the lowest position of the edge , the limiting plate 5, the guide post 4, the connecting block 2 and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com