Long-service-life efficient safe type chain belt tray type conveyor

A conveyor and safety technology, applied in the field of long-life, high-efficiency and safety chain-belt tray conveyors, to achieve the effects of avoiding tooth loss, improving performance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

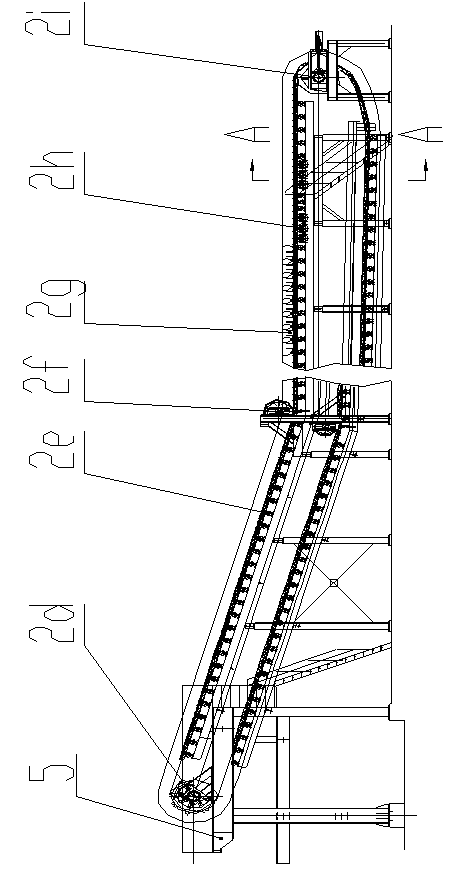

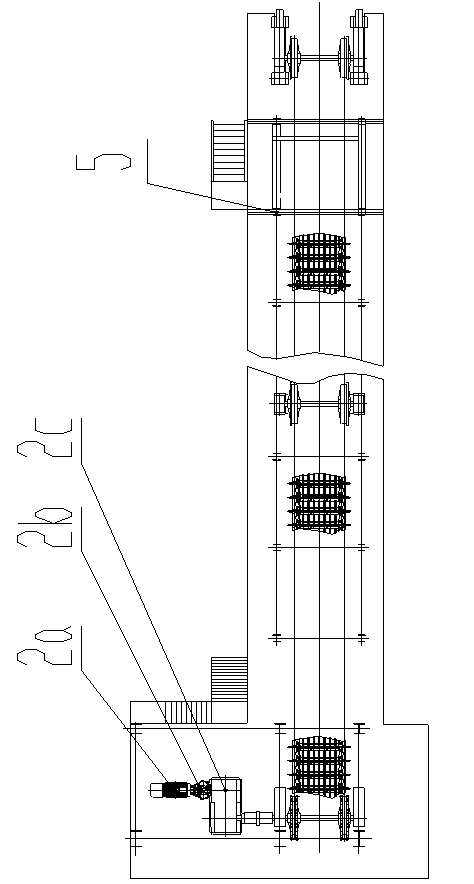

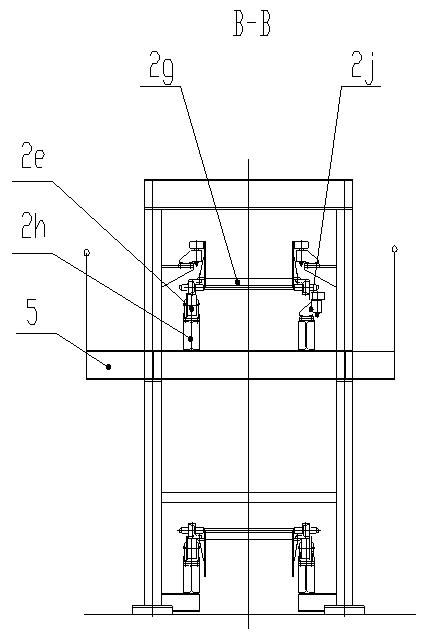

[0064] Such as figure 1 , figure 2 , image 3 As shown, the long-life, high-efficiency and safe chain-belt tray conveyor 2 is mainly composed of a motor 2a, a hydraulic coupling 2b, a reducer 2c, a driving sprocket device 2d, a roller device 2e, a guide wheel 2f, a chain-belt tray device 2g, and a support It consists of idler roller 2h, driven wheel device 2i and chain belt anti-deviation device 2j.

[0065] The electric motor 2a and the speed reducer 2c are connected through the hydraulic coupling 2b, so as to prevent accidents of damage to the overloaded equipment. When the chain-belt pallet conveyor jams during operation, causing the driving torque to increase sharply to exceed the preset torque of the hydraulic coupling, the reducer will no longer run, effectively protecting the chain-belt pallet conveyor equipment and Or the safety of the reducer and or the motor prevents accidents such as the chain-belt pallet conveyor equipment being pulled out, the reducer being op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com