Water cooled rubber crusher

A rubber breaker and water cooling technology, which is applied in recycling technology, plastic recycling, etc., can solve the problem of high temperature of the roller wall, and achieve obvious effects and good gel breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

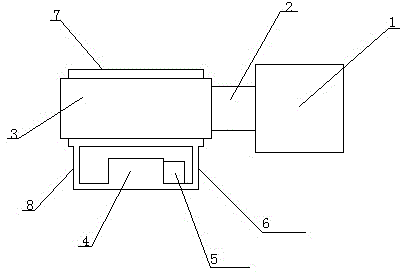

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, a water-cooled rubber breaking machine, including a motor 1, a feed port 2 and a roller 3, the right side of the roller 3 is provided with a feed port 2, and the right side of the feed port 2 is provided There is a motor 1, a cooling water pool 4 is provided under the roller 3, the cooling water pool 4 is connected to a water inlet 6 and a water outlet 8, a water pump 5 is arranged on the right side of the cooling water pool 4, and the water inlet 6 is connected to a cooling water pipe 7 , the cooling water pipe 7 is connected to the water outlet 8 .

[0010] When this water-cooled rubber breaker is working, start the water pump 5 to cool the roller 3, and the cooling water circulates through the water inlet 6 to make the cooling water pipe 7, and finally flows back into the cooling water pool 4 through the water outlet 8, and the use effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com