Abrasive belt grinder steel pipe fixing device

A technology for abrasive belt grinding and fixing devices, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc. It can solve the problems that round pipes are not easy to clamp and easy to slide up and down, and achieve strong fastening force, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be further described in detail below.

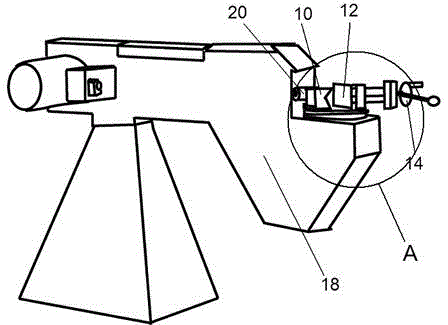

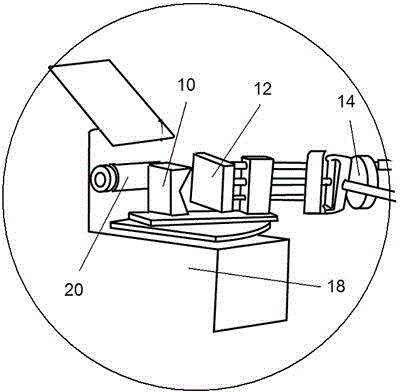

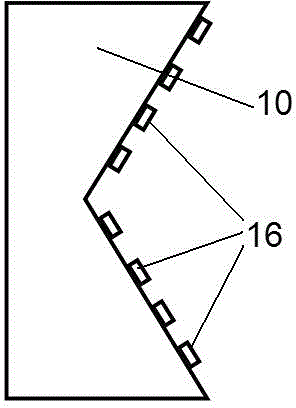

[0013] like Figure 1 to Figure 4 As shown, a steel pipe fixing device for a belt grinder of the present invention includes a fixed block 10 and a moving block 12 facing the fixed block 10 , wherein the moving block 12 can move relative to the fixed block 10 under the drive of the handle 14 . The cross section of the side of the fixed block 10 opposite to the moving block 12 is V-shaped. Several protruding friction blocks 16 are arranged on the side.

[0014] When the steel pipe fixing device of the abrasive belt grinder of the present invention is in use, the round pipe is placed in the middle of the V-shaped surface of the fixed block 10, and then the handle 14 drives the moving block 12 to move relative to the fixed block 10, and the round pipe is clamped in the moving Between the block 12 and the fixed block 10. Start the abrasive belt wheel 20 of the abrasive belt grinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com