Wide lead belt production line continuous rolling synchronous control system

A technology of synchronous control and control system, applied in the direction of tension/pressure control, etc., can solve problems such as weakness, rigidity, and inability to adjust in different situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

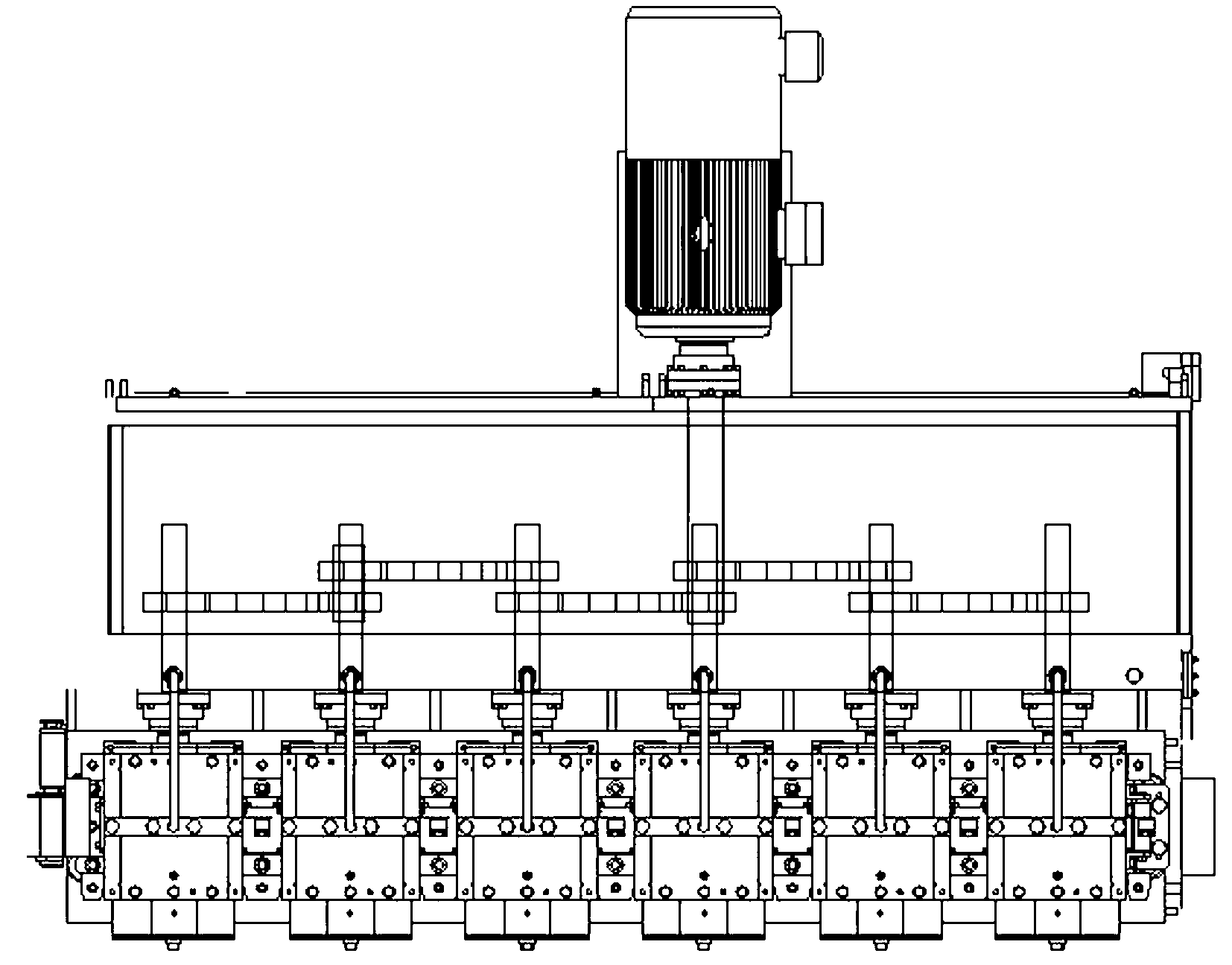

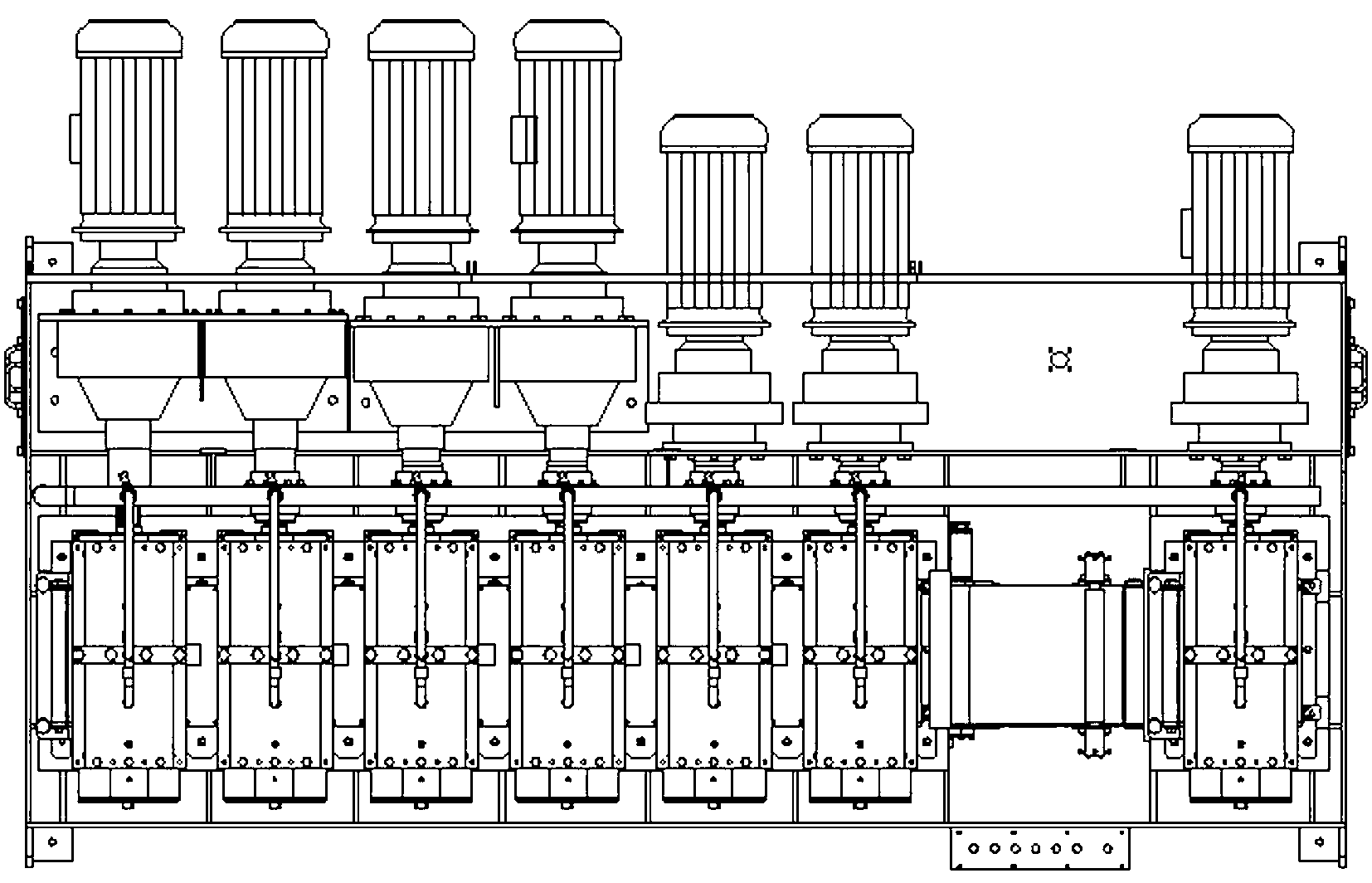

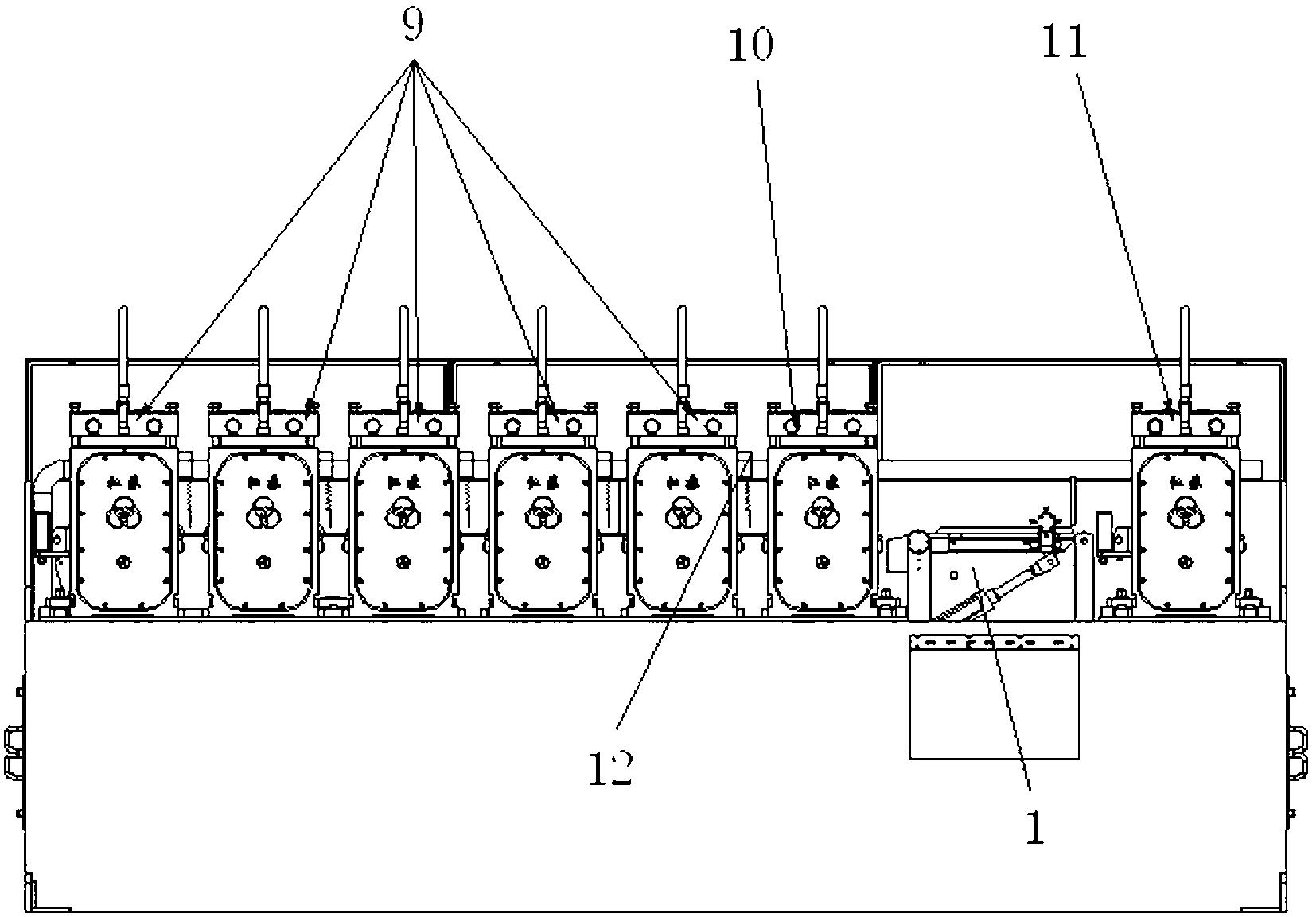

[0030] Such as figure 2 -Shown in 7, a kind of wide lead strip production line continuous rolling synchronous control system of the present invention comprises 7 motors, 6 roughing mills and 1 finishing mill, each motor controls a roughing mill or a finishing mill independently, all motors All are connected to the PLC control system, wherein the last roughing mill, that is, the roughing mill A, is followed by the finishing mill 11, and each of the five roughing mills except the roughing mill A is provided with a needle microswitch 12, The needle micro switch 12 is used to monitor whether the lead strips are accumulated between the rough rolling mills, and feed back the monitoring results to the PLC control system. If there is lead band accumulation between the rough rolling mills, the needle microswitch 12 will feed back the monitoring results to the PLC control system, and the PLC control system will control the speed of the corresponding rough rolling mills, so that the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com