Carbonate inhibitor and preparation method and application thereof

A technology of inhibitors and carbonates, applied in solid separation, flotation, etc., can solve the problems of high cost and difficulty in wastewater treatment, and achieve good environmental benefits, cost savings, and increased differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 50g of grass coal (the mass percentage of organic matter is 50%), grind it to a particle size of less than 1mm, mix it with water at a mass ratio of 1:10 and stir evenly, add 50% of the mass percentage of grass coal Na 2 CO 3 , shaking and extracting at 85°C for 60 minutes. After the extraction process is completed, filter the slurry to remove residue (the diameter of the filter hole is 40 μm), and the obtained filtrate is the carbonate inhibitor.

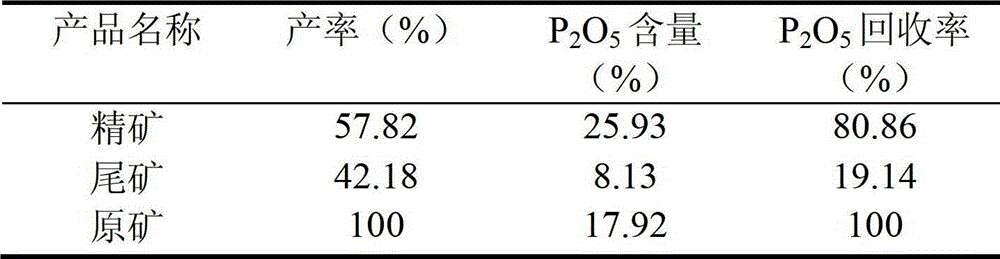

[0023] Taking the three-layer ore of Dayukou phosphate rock in Hubei as the raw ore, the positive flotation effect of the carbonate inhibitor prepared in this example was investigated. The specific flotation method is as follows: Weigh 300g of phosphate rock sample (mineral particle size is 2mm, accounting for 100%) and place it in a rod mill, add 148ml of clean water with a measuring cylinder (grinding concentration is 66.96%). Put the ground pulp into a 0.75L flotation tank, adjust the temperature to 52±2°C, and add...

Embodiment 2

[0031] Take 50g of grass coal (the mass percentage of organic matter is 60%), grind it to a particle size of less than 1mm, mix it with water at a mass ratio of 1:10 and stir evenly, add 25% of grass coal mass percentage Na 2 CO 3 , shaking and extracting at 85°C for 60 minutes. After the extraction process is completed, filter the slurry to remove residue (the diameter of the filter hole is 40 μm), and the obtained filtrate is the carbonate inhibitor.

[0032] According to the method of Example 1, the positive flotation effect of the obtained carbonate inhibitor prepared in this example was investigated.

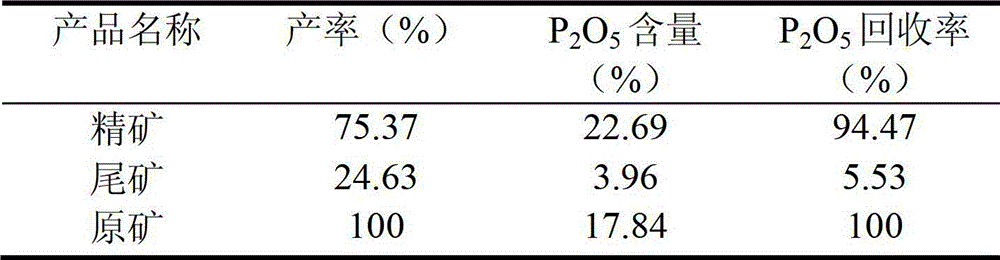

[0033] The test indicators are shown in Table 2:

[0034] Table 2. Test results of Dayukou three-layer mine

[0035]

[0036] It can be seen from the table that after the raw ore is separated by flotation, the concentrate P 2 o 5 content increased from 17.84% to 22.69%, and the concentrate recovery rate was 94.47%; tailings P 2 o 5 The content is 3.96%, and its re...

Embodiment 3

[0038] Take 50g of grass coal (the mass percentage of organic matter is 70%), grind it to a particle size of less than 1mm, mix it with water at a mass ratio of 1:10 and stir evenly, add 12.5% of grass coal mass percentage Na 2 CO 3 , shaking and extracting at 85°C for 60 minutes. After the extraction process is completed, filter the slurry to remove slag (the diameter of the filter hole is 100 μm), and the obtained filtrate is the carbonate inhibitor.

[0039] According to the method of Example 1, the positive flotation effect of the obtained carbonate inhibitor prepared in this example was investigated.

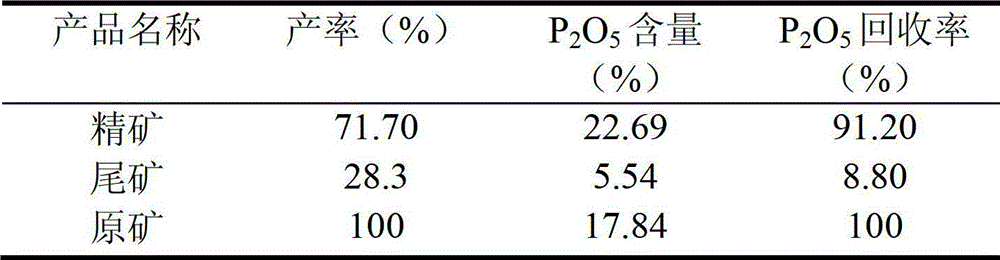

[0040] The test indicators are shown in Table 3:

[0041] Table 3. Test results of Dayukou three-layer mine

[0042]

[0043] It can be seen from the table that after the raw ore is separated by flotation, the concentrate P 2 o 5 content increased from 17.84% to 22.69%, and the concentrate recovery rate was 91.20%; tailings P 2 o 5 The content is 5.54%, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com