Reaction vessel negative pressure distilled water separating apparatus

A separation device, distilled water technology, applied in liquid separation, separation method, grease/oily substance/float removal device, etc., can solve the problems of delayed reaction time, reduced production efficiency, poor solvent and water separation effect, etc. To achieve the effect of improving separation effect and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

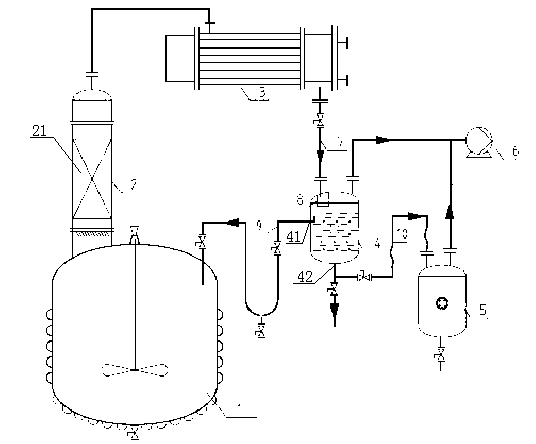

[0013] like figure 1 As shown, the present invention includes a reactor body 1, the reactor body 1 is provided with a separation device, and the separation device includes a distillation tower 2, a condenser 3, a separator 4, a receiving tank 5 and a vacuum pump 6, and the reactor body 1 The distillation tower 2 is communicated with the distillation tower 2 through a pipeline, and the distillation tower 2 is communicated with the inlet of the condenser 3 through a pipeline, and the outlet of the condenser 3 is communicated with the separator 4 through the discharge pipe 7, and a return port 41 is arranged on one side of the separator 4, and the return port 41 passes through The return pipe 9 communicates with the reactor body 1, and the bottom of the separator 4 is provided with a water riser 42, and the water riser 42 communicates with the receiving tank 5 through the rising water pipe 10, and the separator 4 and the top of the receiving tank 5 are respectively connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com